Vertical eyclone filtering dust collector

A cyclone filtration and dust collector technology, applied in the fields of dispersed particle filtration, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of easy breakage, bury filter rods, reduce separation efficiency, etc., and achieve the effect of high-efficiency backwashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

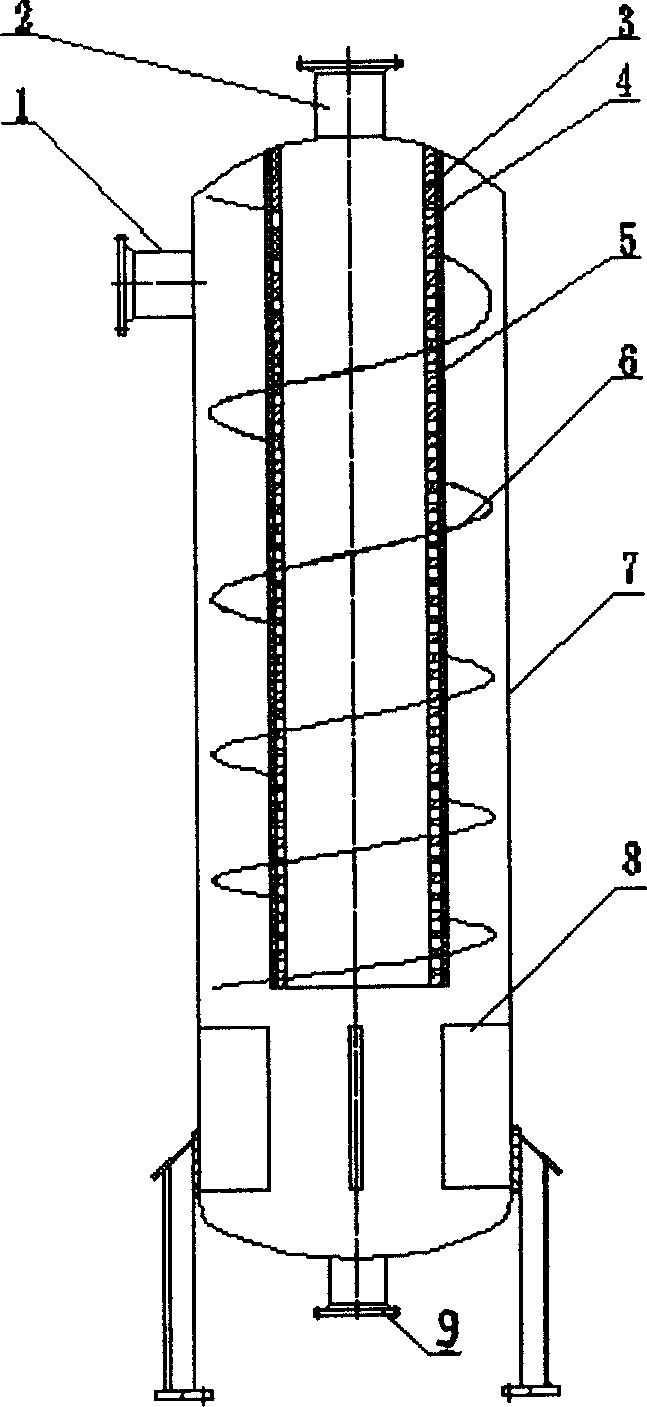

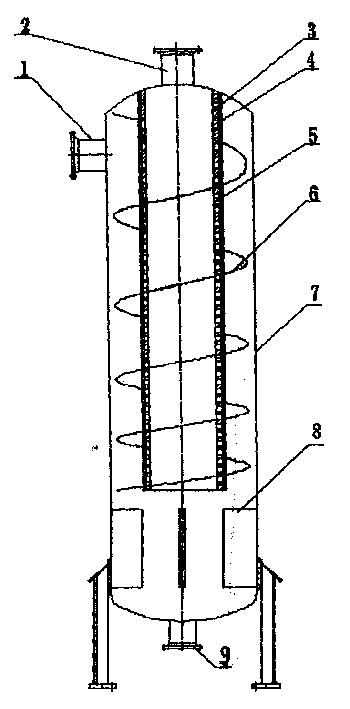

[0019] Further illustrate the present invention below in conjunction with accompanying drawing.

[0020] Referring to Fig. 1, the vertical cyclone filter dust collector is mainly composed of a separator shell 7, a filter rod 3, a filter screen 5 wound on the filter rod, etc. It is characterized in that the filter rod 3 has an opening 4, And the number of openings is sparse on the top and dense on the bottom, its upper end is connected with the separator exhaust port 2, and its lower end is sealed, and a helical guide vane 6 with variable pitch is installed on the filter rod, and the pitch gradually becomes smaller from top to bottom, so There is a certain gap between the spiral guide vane 6 and the inner wall of the separator shell 7, and a sewage outlet 9 is also provided at the bottom of the separator.

[0021] Installing the broken rotary plate 8 at the lower part of the dust collector can effectively prevent the natural gas from continuing to swirl after passing through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com