Collar shape keeping piece

A technology for retaining parts and collars, applied to collars, special packaging items, clothing, etc., can solve the problems of increased manufacturing costs, complicated operations, and difficulty in realizing automation, and achieve the effect of preventing downward deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

reference example 1

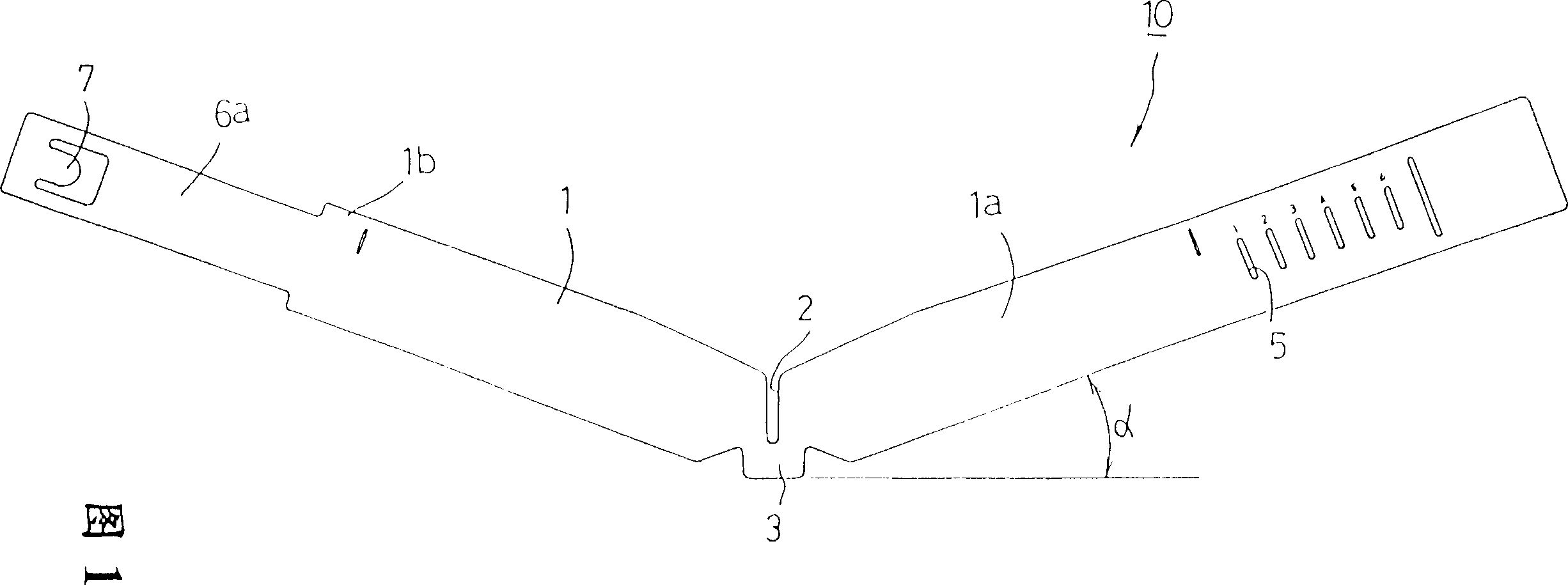

[0043] 1 shown in FIG. 1 is a shape holder main body formed of a flexible synthetic resin thin plate. The shape holder main body 1 has two left and right pieces 1a, 1b ascending and slanting from the center to the end to form a V-shape. The inclination α is 15°-30°, and the ideal angle is 20°.

[0044]In addition, in the shape holder main body 1, the tip portion of the left piece 1b is formed as an insertion portion 6a with a slightly narrow width.

[0045] 2 is a notch formed at the upper edge of the central portion of the shape holder main body 1. 3 is a support part formed by protruding from the lower part of the cutout 2.

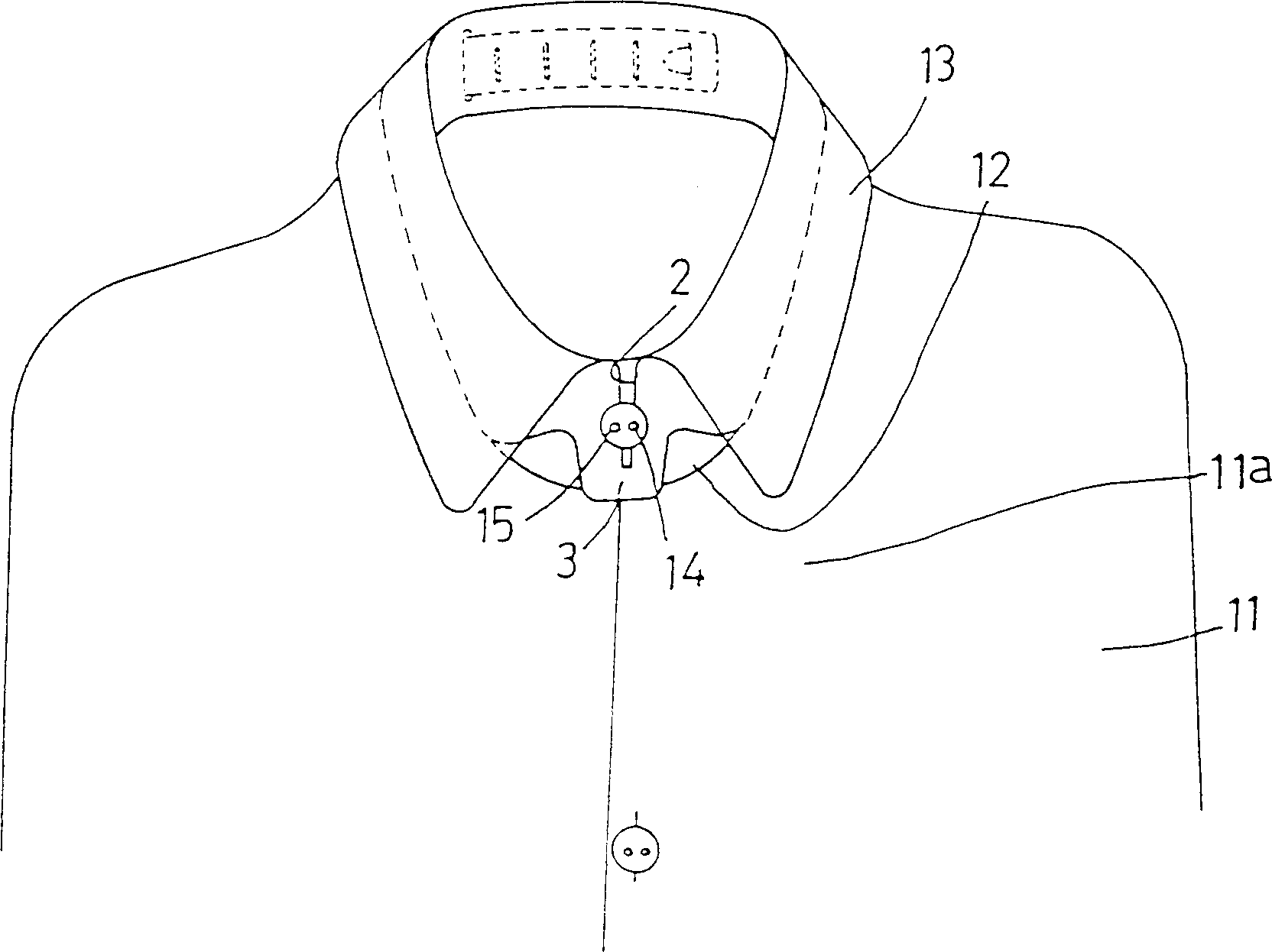

[0046] The cutout 2 and the supporting portion 3 are formed with such a size and position that when the mounting line 15 for attaching the button 14 is fitted into the cutout 2 under the button 14 mounted on the lower collar, The lower end of the supporting portion 3 is in contact with the root portion where the lower collar 12 is mounted on the front and r...

reference example 2

[0079] Such as Figure 8 As shown, the shape holder main body 1 of the reference example of this embodiment is composed of a flexible synthetic resin thin plate like the reference example 1 and the above-mentioned embodiment, and the left and right two pieces 1a, 1b are the same as those of the reference example of the above-mentioned embodiment. 1 Similarly, it has a predetermined angle (15°-30°, preferably about 20°), and is inclined upward toward both ends.

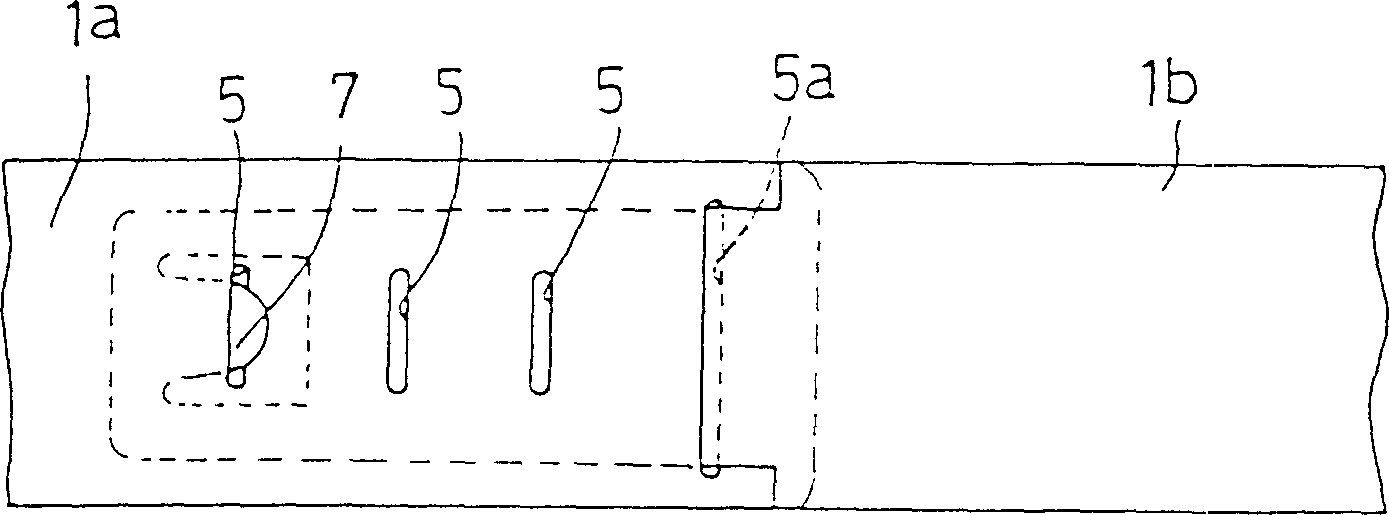

[0080] Moreover, similar to the above-mentioned embodiments, the right piece 1a is provided with an insertion hole 5a and a plurality of stop holes 5, and a narrow insertion portion 6a is formed at the top end of the left piece 1b, and the insertion portion 6a is formed by The incision forms a protruding piece 7.

[0081] The shape retainer 10 constituted by the shape retainer body 1 described above is connected along the inner circumference of the lower collar 12 in the same manner as in the above-mentioned embodiments. B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com