Backlight plate device

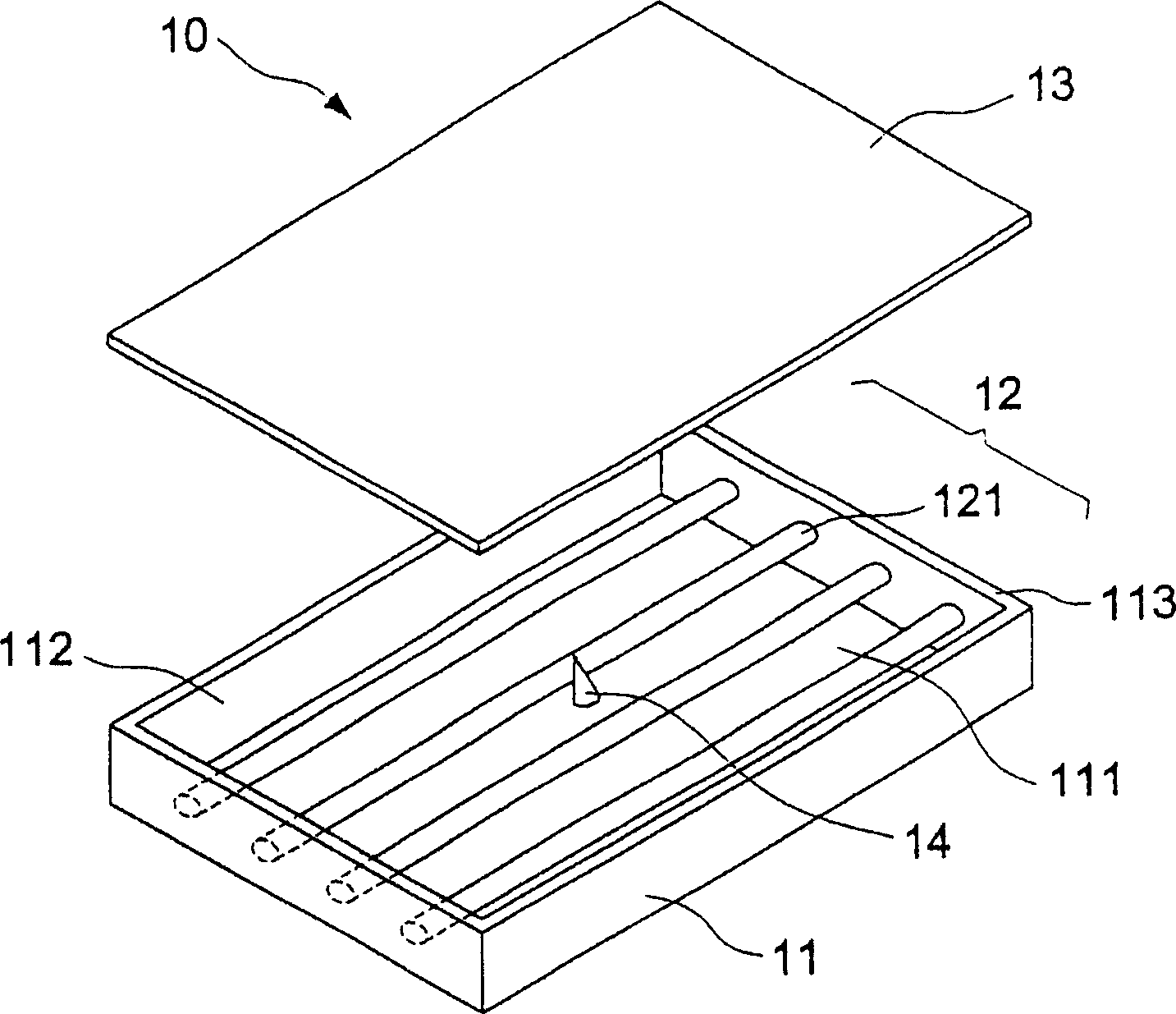

A technology for a backlight plate and a diffuser plate, which is applied in the directions of light guides, optics, and optical elements, etc., can solve problems such as the loss of illumination light source, the increase of the deformation of the diffuser plate 13 and the downward depression, and the phenomenon of bright and dark images.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

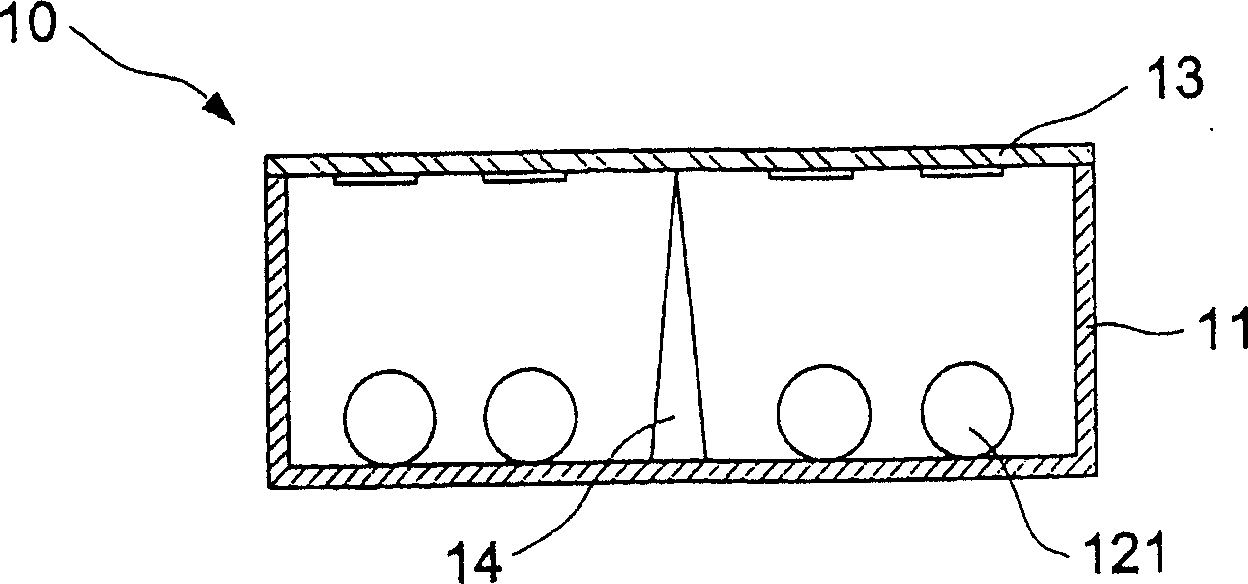

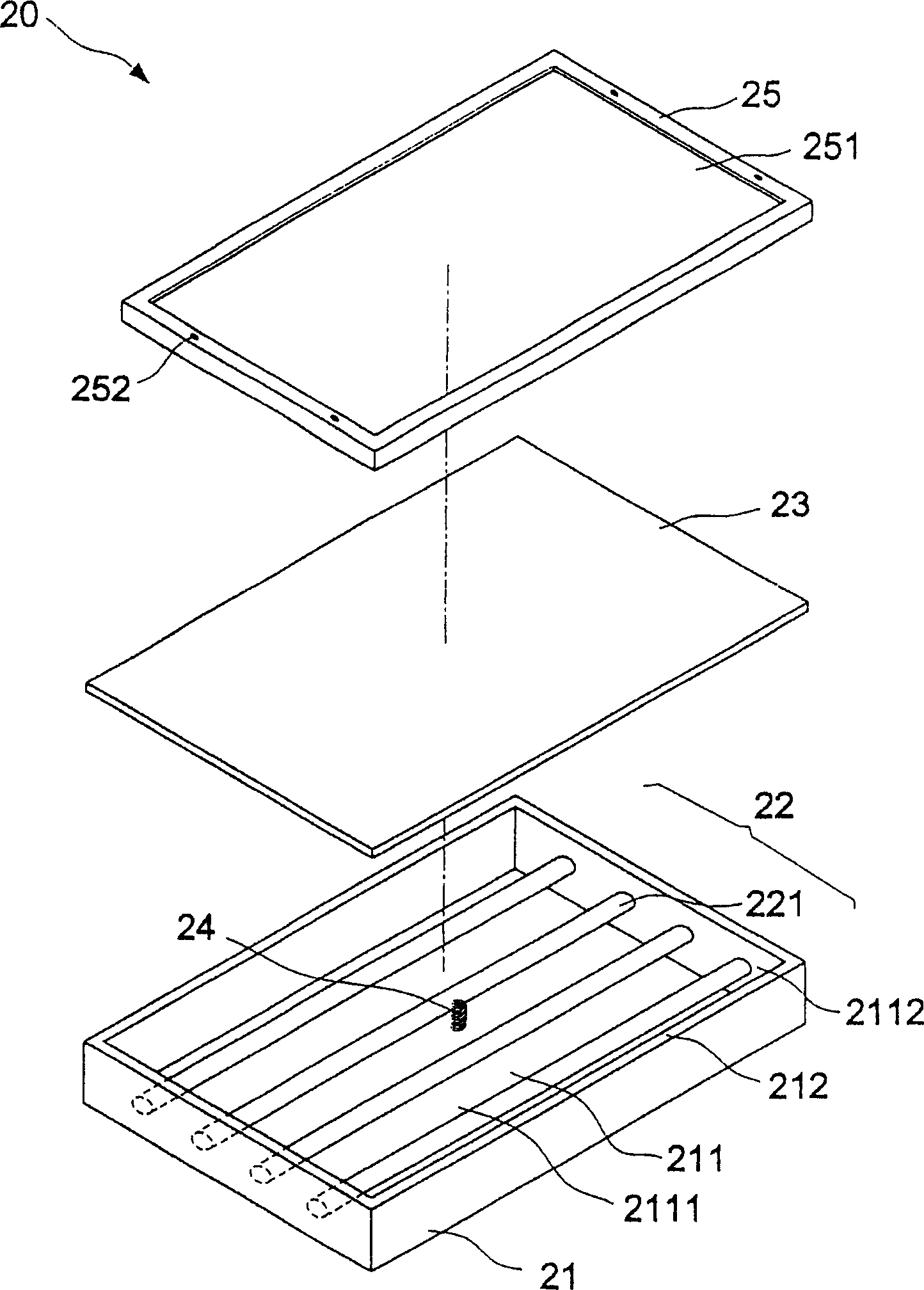

[0019] refer to image 3 , the backlight device 20 of the present invention includes a rectangular frame body 21, a light source group 22, a diffusion plate 23, at least one elastic element 24 and a cover plate 25;

[0020] Wherein the rectangular frame body 21 has a groove 211 and a top surface 212, the bottom surface 2111 and the inner side wall surface 2112 of the groove 211 are pasted with a reflective layer to reflect the light beam provided by the light source group 22 to the diffuser plate 23; the light source The group 22 is arranged in the groove 211 and includes a plurality of cold cathode fluorescent lamps 221 (CCFL). The lamps 221 are horizontally arranged in the groove 211 at an appropriate interval, and the two ends are respectively connected to the inner wall surface 2112 of the frame body 21 and fixed. The diffusion plate 23 is arranged on the top surface 212 of the rectangular frame body 21, and the surface of the diffusion plate 23 facing the lamp 221 serves ...

no. 2 example

[0025] refer to Figure 7 As shown, the present embodiment is the same as the above-mentioned first embodiment or equivalent elements are marked with the same figure number. The difference between this embodiment and the above-mentioned embodiment is that the elastic element 24 can also be a spring made of metal, and the elastic element 24 A convex body 241 can be arranged above the elastic element 24. Since the spring of the transparent or highly reflective optical material of the first embodiment is replaced, the cost can be reduced, and the convex body 241 can be made of a transparent material or a highly reflective material. For example, this embodiment adopts a tapered convex body 241 of transparent material, so that the contact surface between the convex body 241 and the diffusion plate 23 is reduced and does not block light, so as to avoid black spots appearing on the diffusion plate 23 . In addition, the convex body 241 can also be made of elastic material to prevent i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com