Multifunctional dismantled cleaning method and its cleaning device

A cleaning device and multi-functional technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of unreachable parts, unfavorable environmental protection, increased costs and working hours, etc., to achieve the method Fast, site-free, resource-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

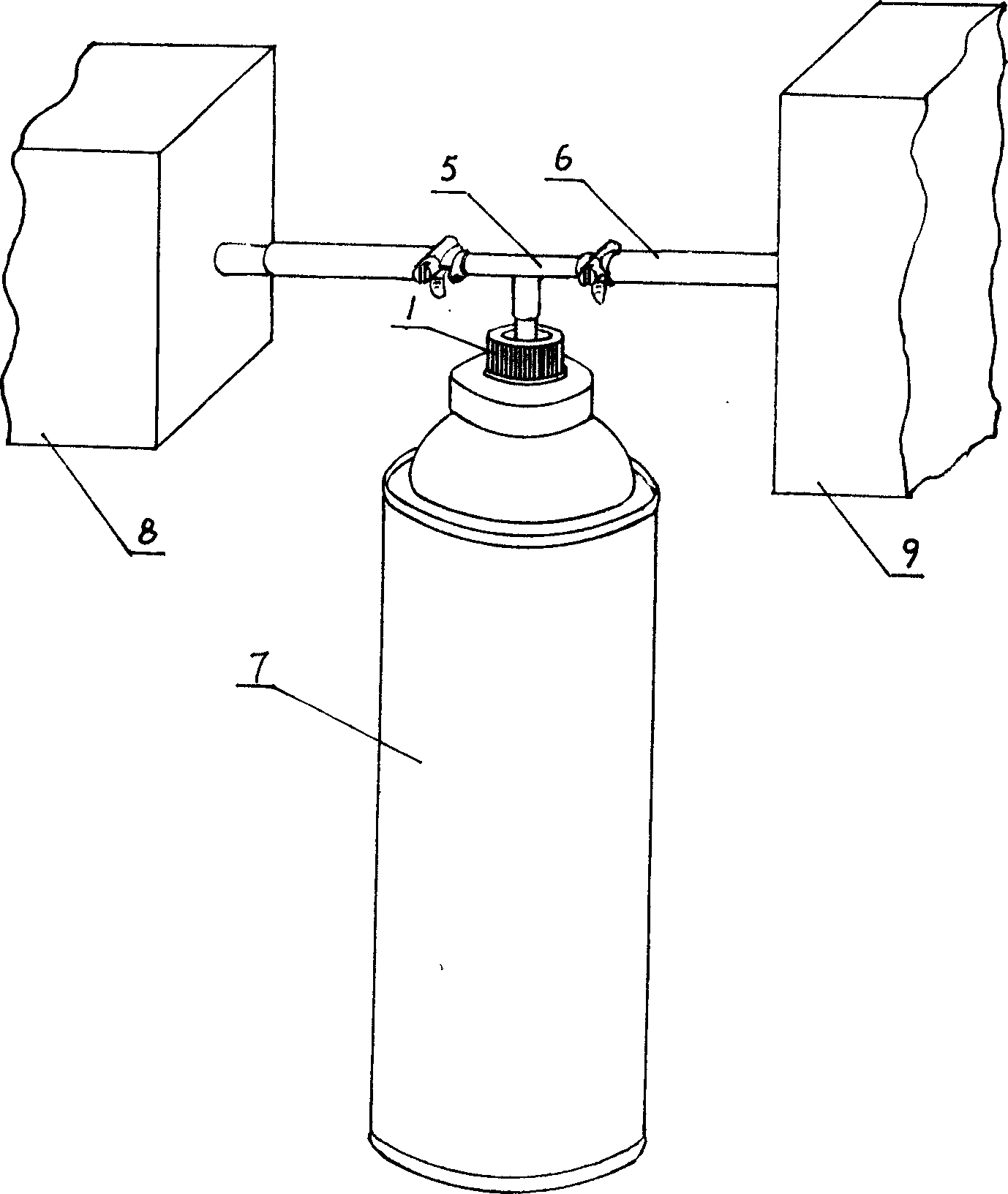

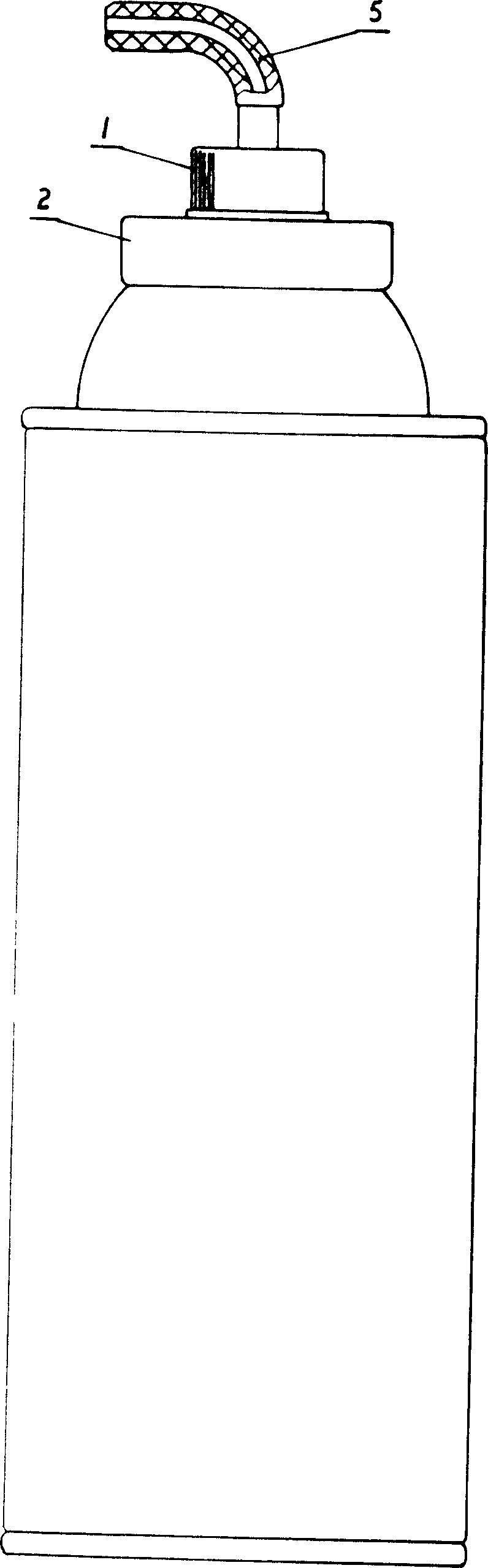

[0012] as attached figure 1 As shown, to adopt the method of the present invention to clean, it is only necessary to connect the cleaning device of the present invention in the oil delivery pipeline 6 between the oil reservoir 8 and the injector 9, and to observe the flow of the cleaning liquid through the transparent connecting valve 5 by rotating the regulating switch 1. Depending on the size of the output and the speed of the output, the cleaning solution can be a prepared chemical cleaning agent. The cleaning liquid in the aerosol pressure tank 7 flows into the pre-cleaning equipment through the main oil pipeline 6 of the equipment under the pressure of 0.6-0.8Mpa in the tank for cleaning. Save time and effort. Use the method of the present invention to clean and then connect the main oil pipeline 6 of the equipment.

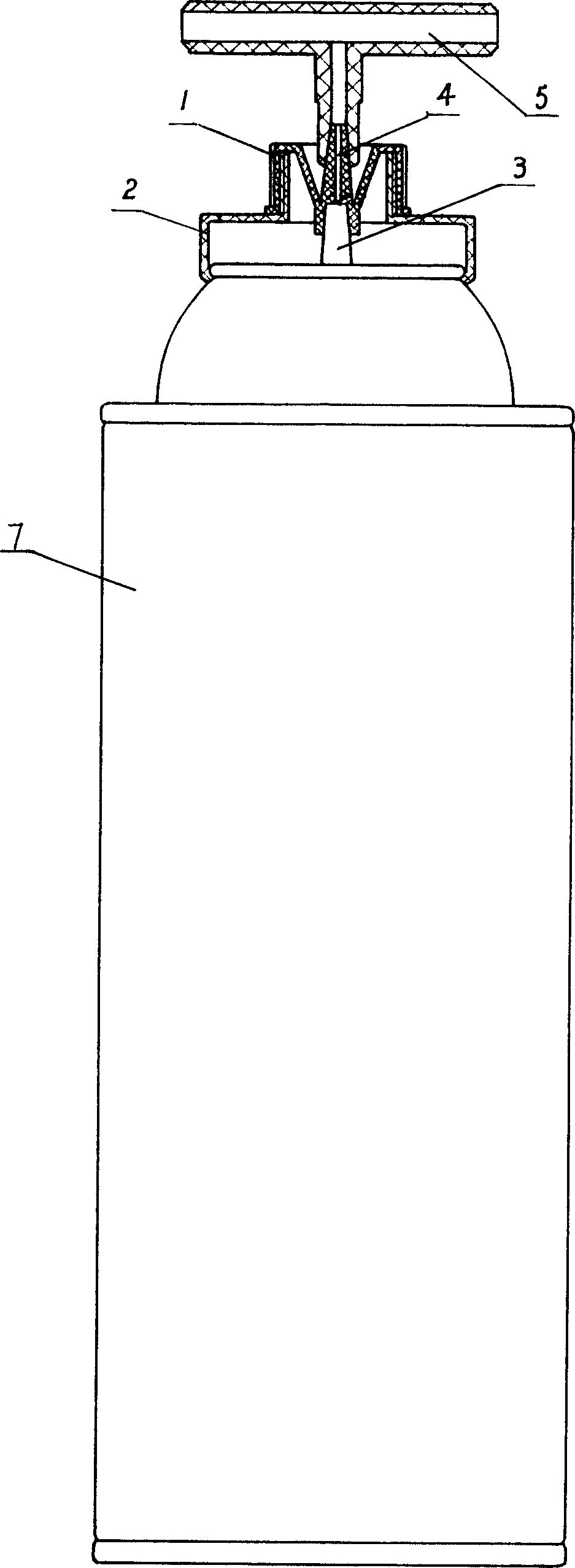

[0013] as attached figure 2 As shown, the cleaning device of the present invention is mainly composed of an aerosol pressure tank 7 and a communication ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com