Ceramic roller cleaning device

A cleaning device, ceramic roller technology, applied in the direction of grinding drive device, cleaning method and utensils, cleaning method using gas flow, etc., can solve the problems of glass surface scratches, unqualified, difficult to do, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]To make the object of the present invention, technical solutions and advantages more clearly understood, the following through examples, the technical solution of the present invention will be further specified in detail. Limitation of a ceramic roller cleaning device.

[0037] Further, in the following detailed description, for ease of interpretation, many specific details are set forth to provide a comprehensive understanding of embodiments of the present disclosure. Apparently, however, one or more embodiments may also be implemented in the absence of these specific details.

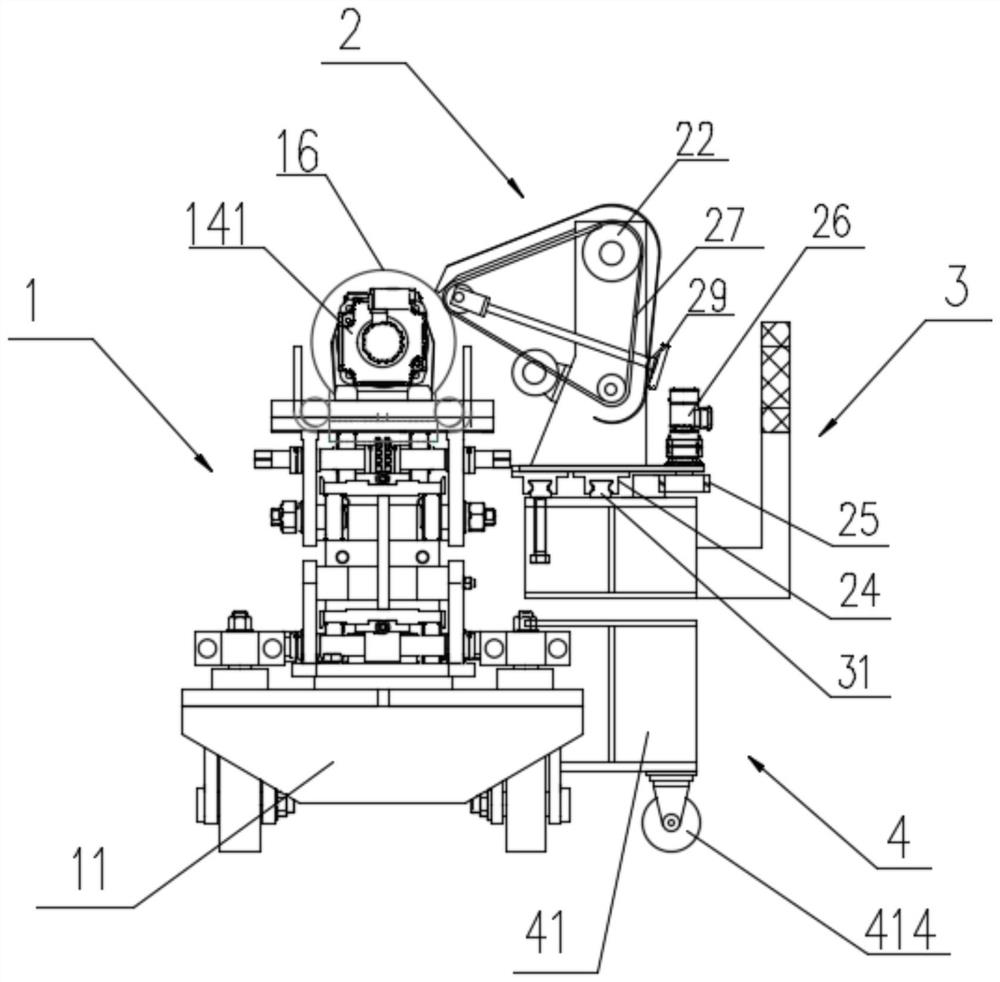

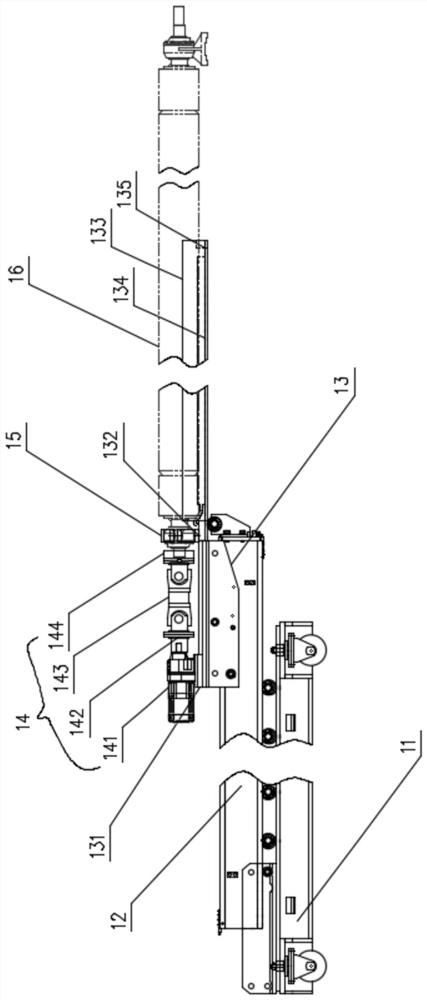

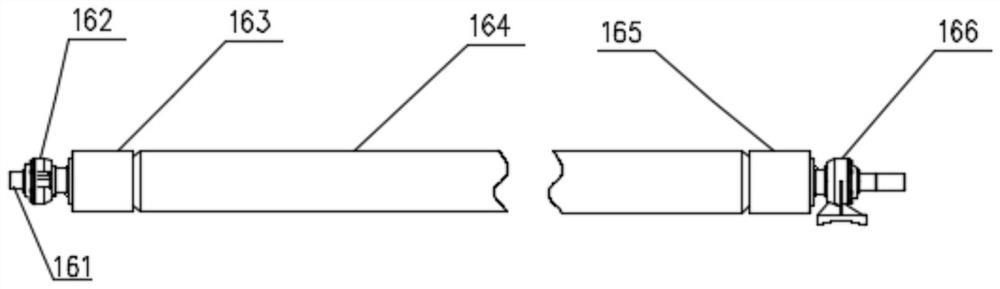

[0038] According to a general technical concept of the present invention, such as Figure 1-10 As shown, a ceramic roller cleaning device is provided, comprising a roller change unit 1, a cleaning unit 2, a walking unit 3 and a quick mounting support 4;

[0039] The roller changing unit 1 includes a fixed base 11 with a first travel wheel 414, a moving seat 13 with a rotating unit 14, a first suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com