Two stroke operation engine and its two stroke operation process

A working method and engine technology, applied in the fields of engines and internal combustion engines, can solve the problems of low work efficiency, high power, and high friction loss of the mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

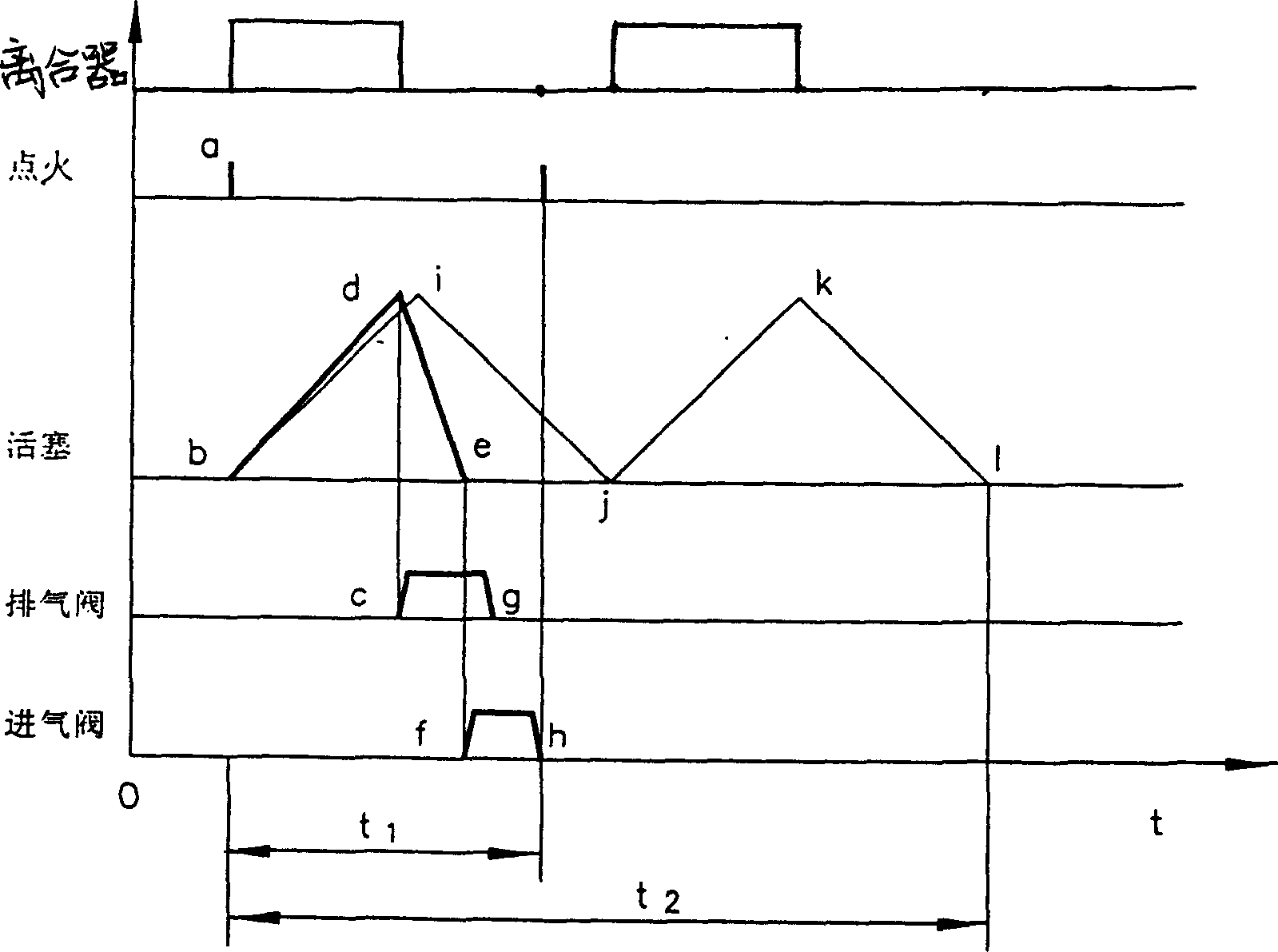

[0017] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings.

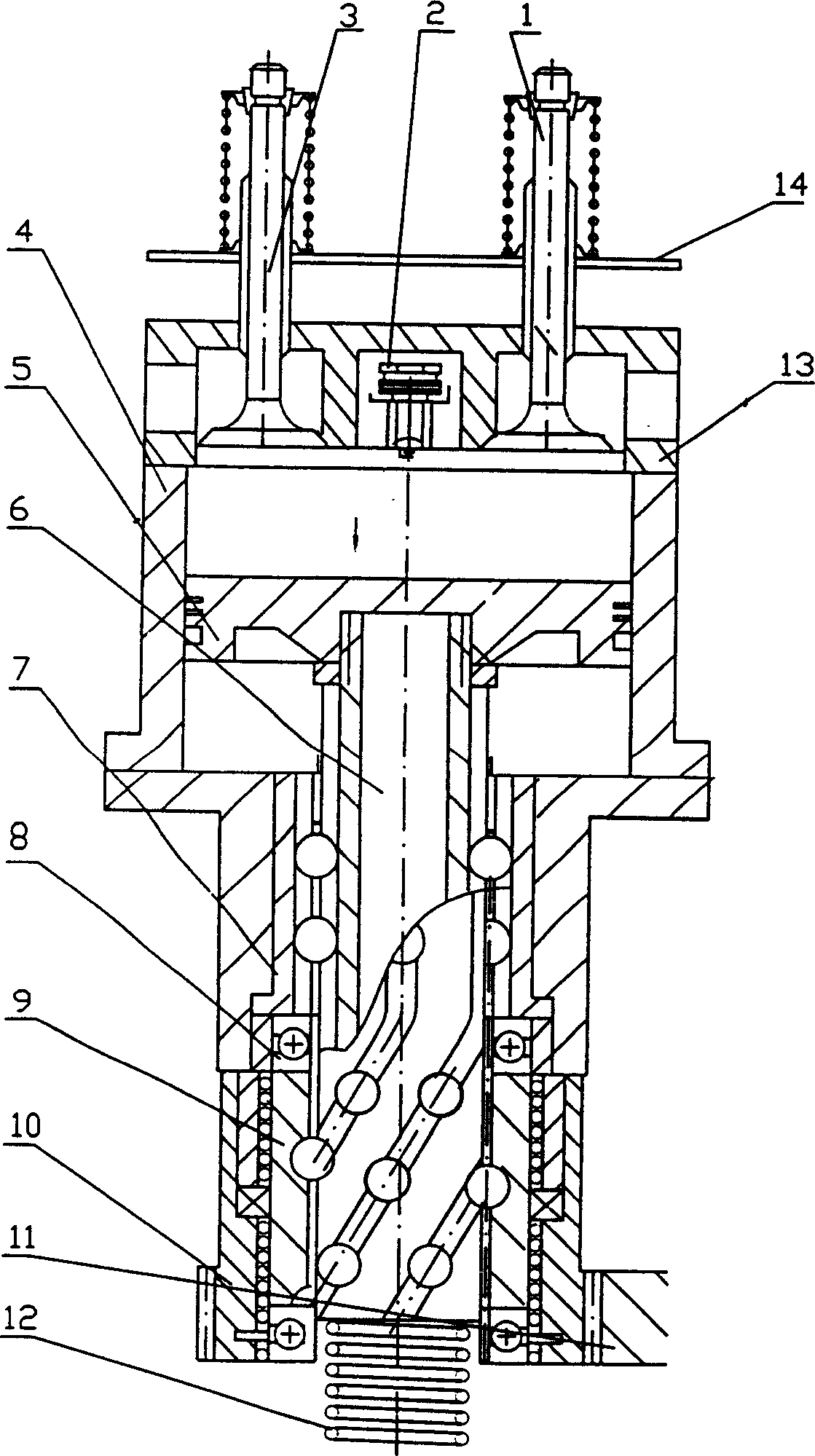

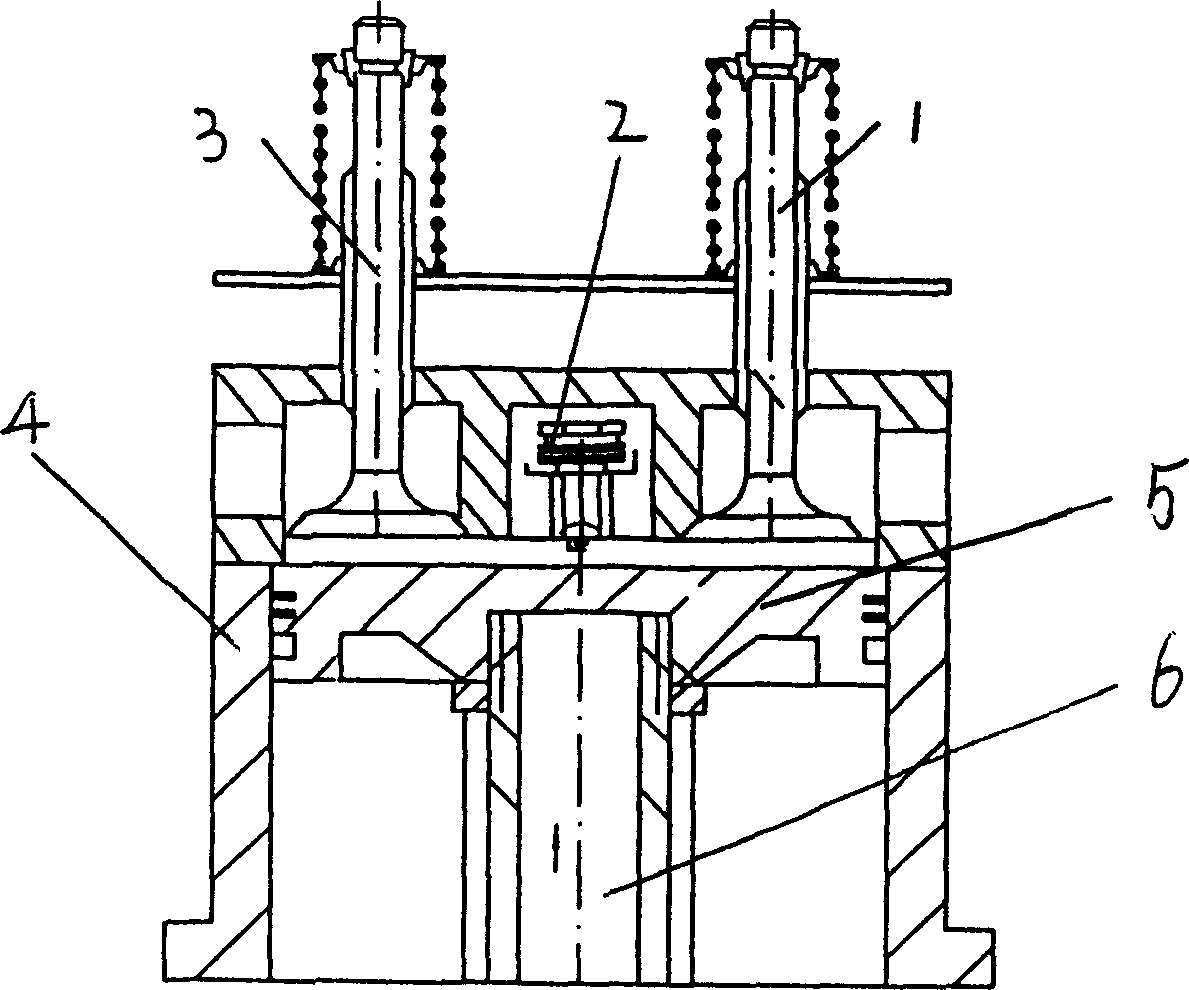

[0018] figure 1 It is a schematic diagram of the structure of the piston motion transformation mechanism.

[0019] In the figure, 1-- is the electromagnetic intake valve, 2-- is the electric spark igniter, 3-- is the electromagnetic exhaust valve, 4-- is the cylinder liner, 5-- is the piston, 6-- is the screw, 7- - is the straight spline cover, 8--thrust bearing, 9--is the spiral sleeve, 10--the electromagnetic rope clutch overcoat and gear, 11--is the output gear, and 12--is the reciprocating spring. 13---is cylinder head, and 14 is the heat insulation plate of fixing electromagnet.

[0020] The above-mentioned two-stroke engine comprises an engine cylinder liner 4, an intake valve 3 controlled by a solenoid valve, an exhaust valve 1, a conversion assembly from linear motion to rotary motion, a return spring 12, and a clutch assembly; it is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com