replaceable nozzle icp generator in plasma chemical etching equipment

A technology for generating device and plasma, which is applied to discharge tubes, electrical components, circuits, etc., to achieve the effects of micro-removal, reduction of heat deposition, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below with reference to the accompanying drawings and examples.

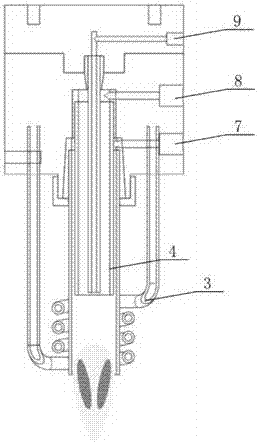

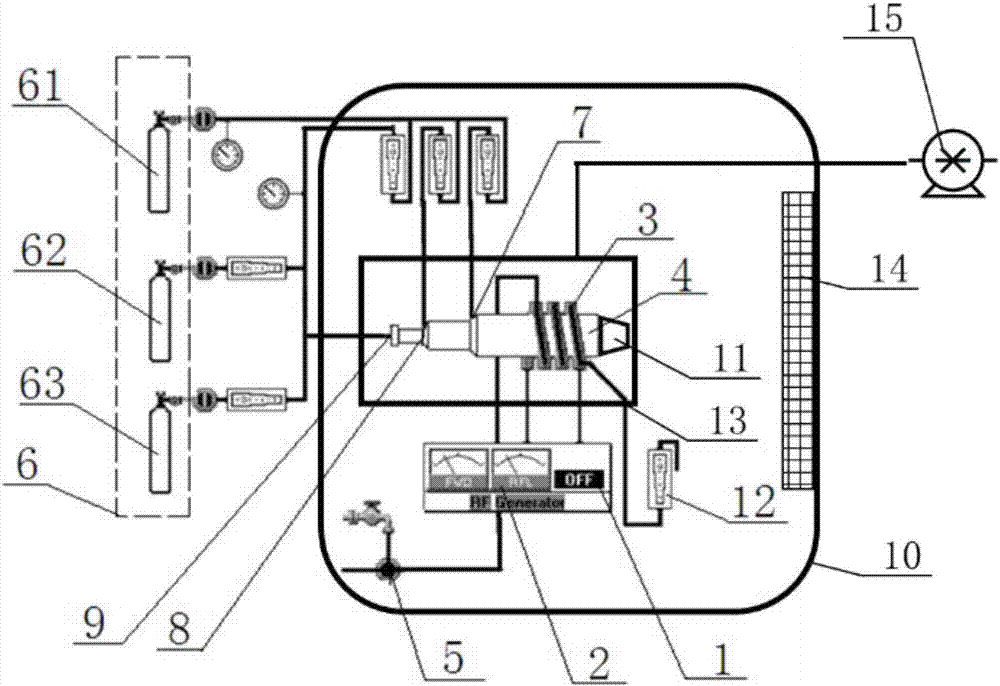

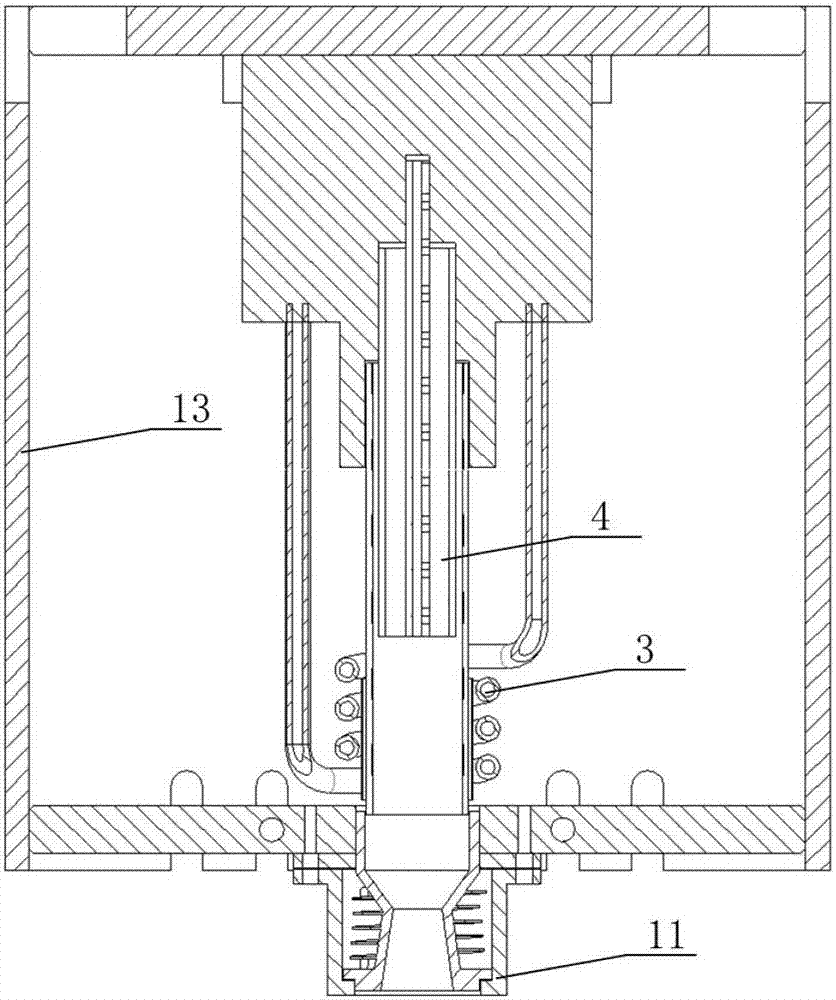

[0027] as attached figure 1 As shown, the present invention provides a replaceable nozzle ICP generating device in plasma chemical etching equipment, the ICP generating device includes a nozzle 11, a plasma torch 4, and an induction coil 3 sleeved outside the plasma torch , high-voltage Tesla ignition coil 12, shielding cover 13, radio frequency power supply 1 and matching device 2, the radio frequency power supply 1 and matching device 2 cooperate to supply power for the induction coil 3, and the high-voltage Tesla ignition coil 12 is powered by an external power supply, said The shielding cover 13 sets the plasma torch 4 and the induction coil 3 inside; the nozzle 11 is detachably fixedly connected to the front end of the plasma torch 4 in the ICP generating device, and the removal is realized by replacing the nozzle 11 with a different inner diameter. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com