An etching process

A technology of etching and etching solution, which is applied in the manufacture of electrical components, semiconductor/solid-state devices, circuits, etc., can solve problems such as uneven etching, unsteady maintenance of oxalic acid concentration, and influence on process effects, so as to ensure stable progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

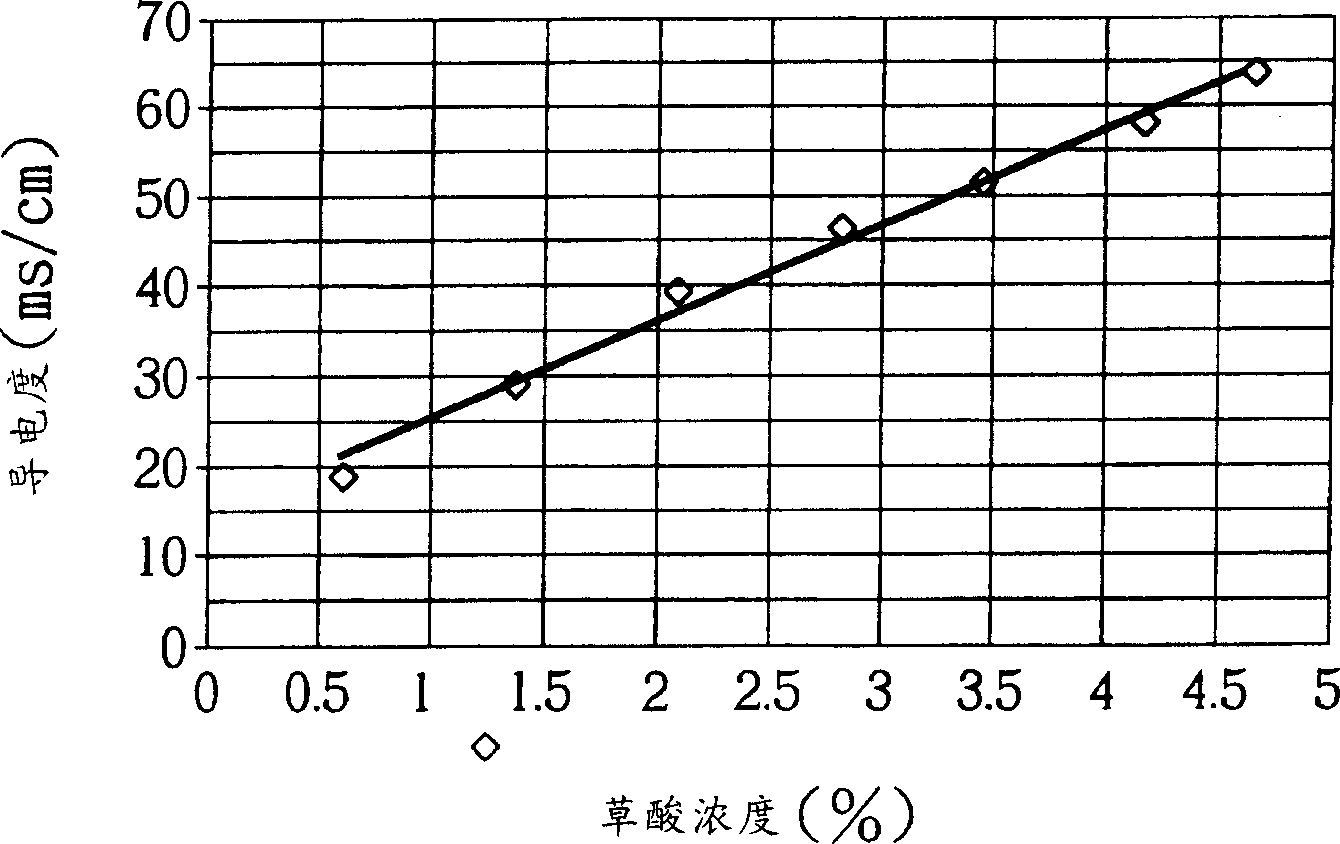

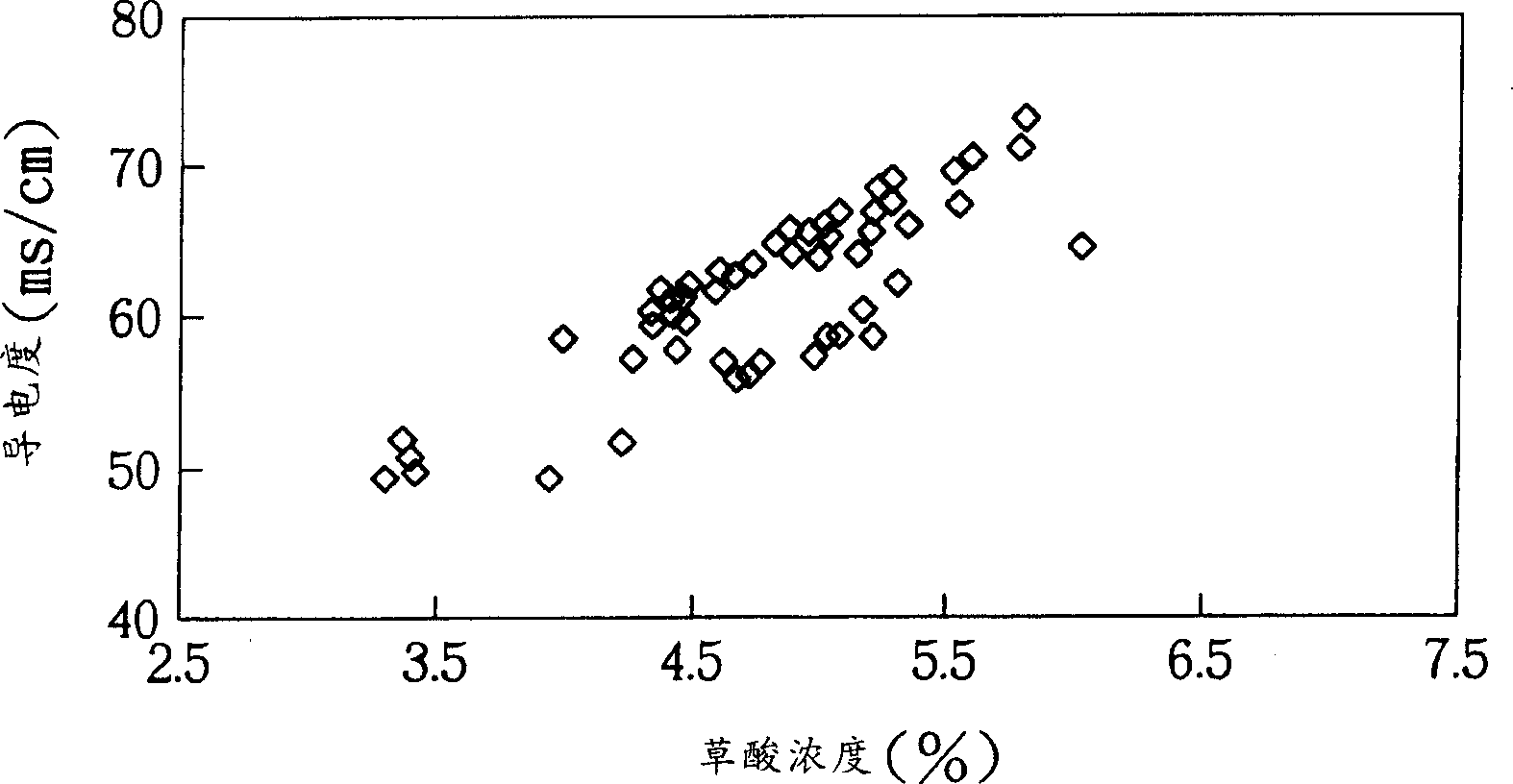

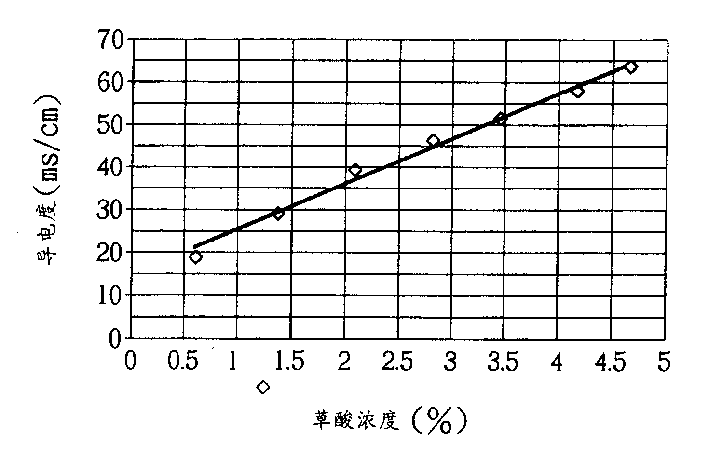

[0012] In a preferred embodiment of the present invention, a liquid crystal display panel is first provided, which includes a glass substrate, a transparent conductive layer is provided on the surface of the substrate, and a mask layer is covered on the surface of the transparent conductive layer to define the pattern of the pixel electrode . Then soak the glass substrate in the oxalic acid etchant, use a conductivity meter to detect the conductivity of the oxalic acid etchant, and adjust the concentration of oxalic acid according to the conductivity, so that its concentration is maintained in a predetermined range, so as to use the oxalic acid etchant to remove impurities. The transparent conductive layer covered by the mask layer defines the pixel electrode. Wherein the material of the transparent conductive layer is indium tin oxide (ITO), and the concentration of the oxalic acid etchant is maintained at about 3.4 wt%.

[0013] Since in the ITO etching process, except for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com