Microfluidic configuration for dosing liquids

A technology of micro-liquid and flow-cutting devices, which can be used in measuring devices, enzymology/microbiology devices, sampling devices, etc., and can solve problems such as pressure shocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

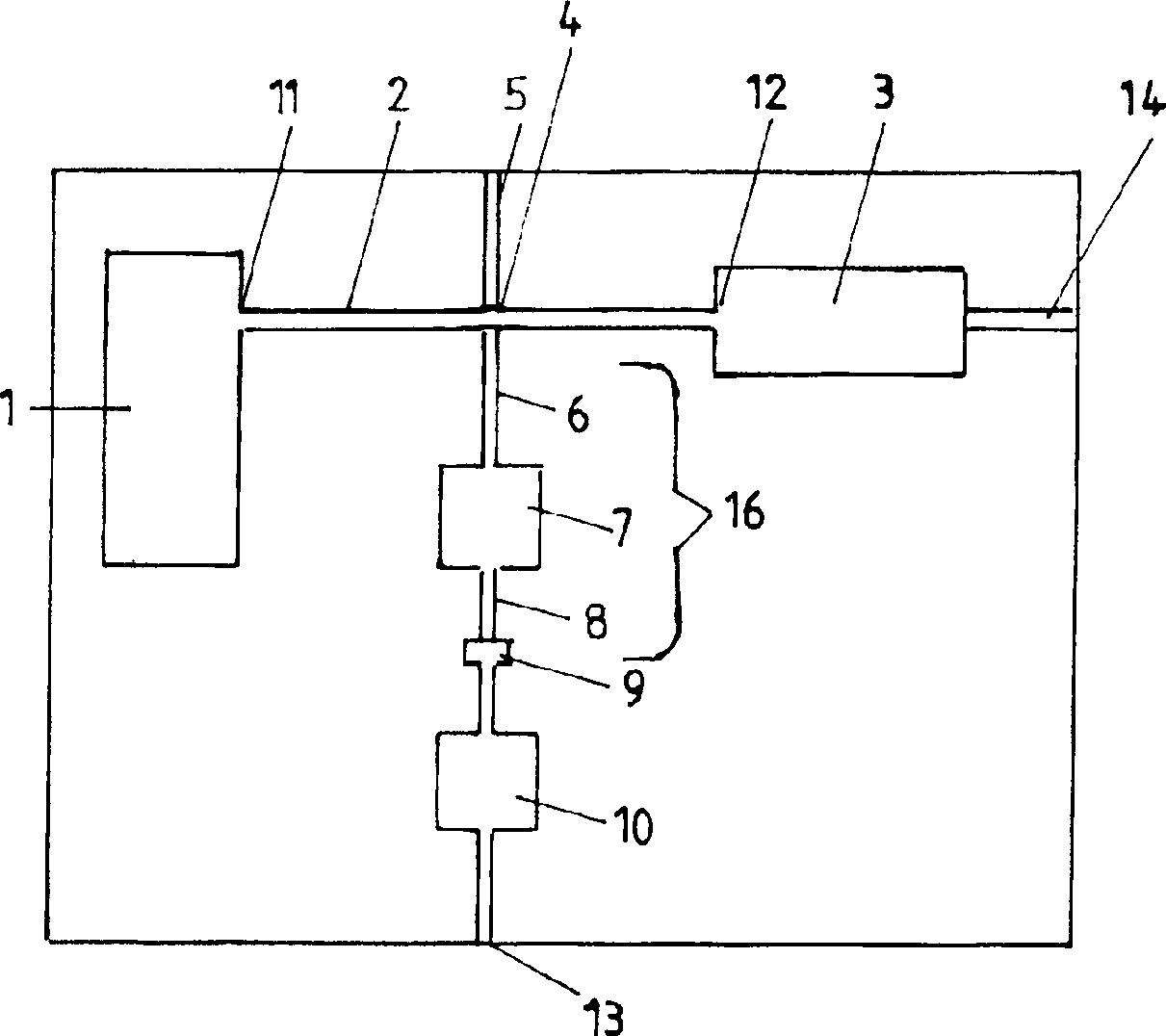

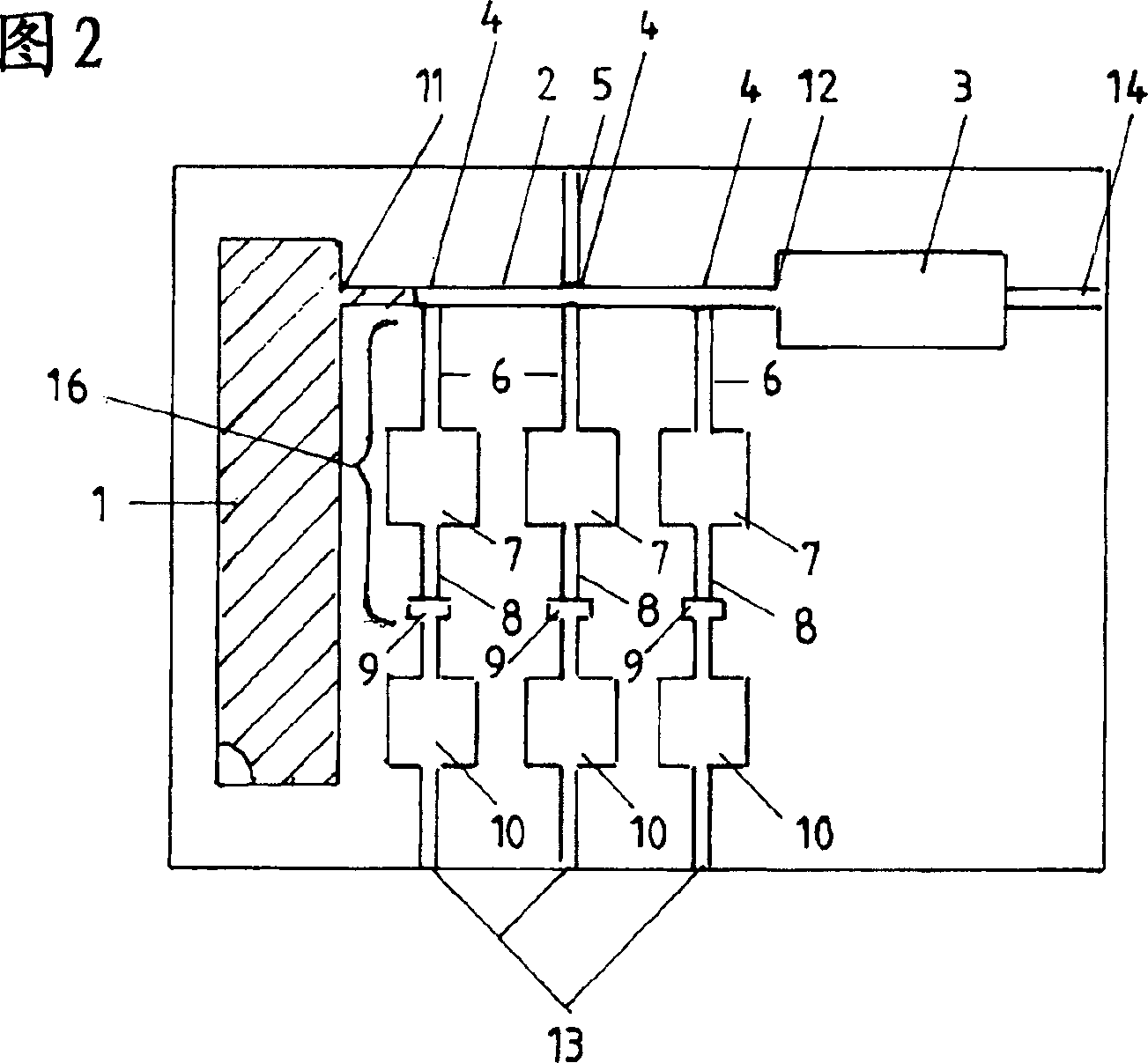

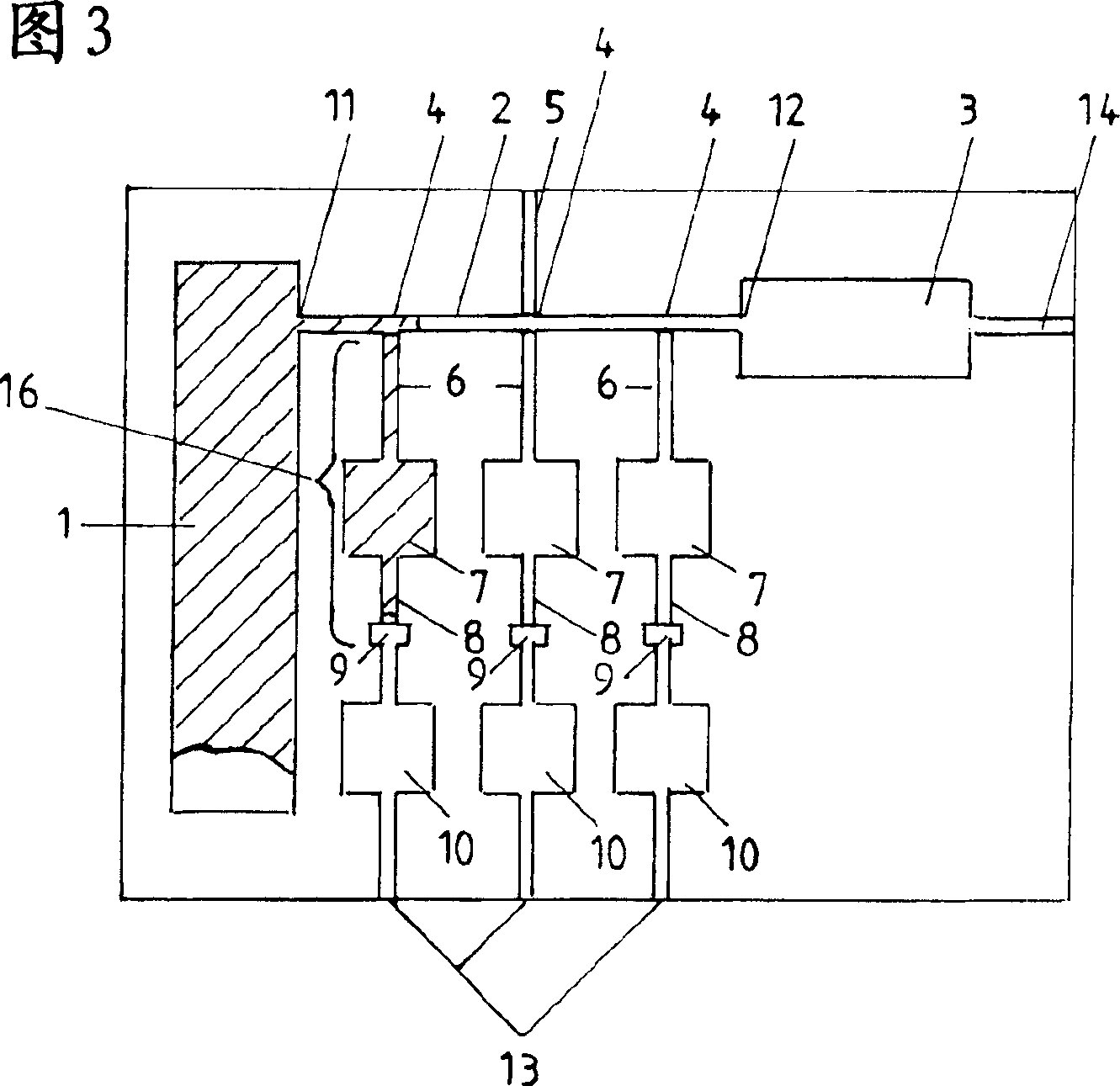

[0023] Figure 1-8c The embodiments of microfluidic devices shown in can be part of a larger general arrangement. For example, they can be provided for the same purpose or for a different purpose with further microfluidic devices, in particular microtiter plates, placed on eg plastic or silicon sample holders.

[0024] Now rely on the basis Figures 8a-8c The simplified embodiment of the present invention illustrates the principles according to the invention. in accordance with Figures 8a-8c The microfluidic device has a first channel 2 with an inlet and an outlet 12. At the tap point 4 of the second channel 2 between the inlet 11 and the outlet 12 , a second channel 16 is tapped off from the first channel 2 . This second channel 16 has a greater capillary force at the tap point 4 than the first channel 2 . Furthermore, the second channel 16 has a precisely defined volume. The liquid entering the first channel 2 through the inlet 11 is transported to the tap point 4 due...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com