Stencil printer

A printing machine and stencil technology, which is applied to stencil printing equipment, printing, office printing equipment, etc., can solve the problems of increasing the cost of stencil printing machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

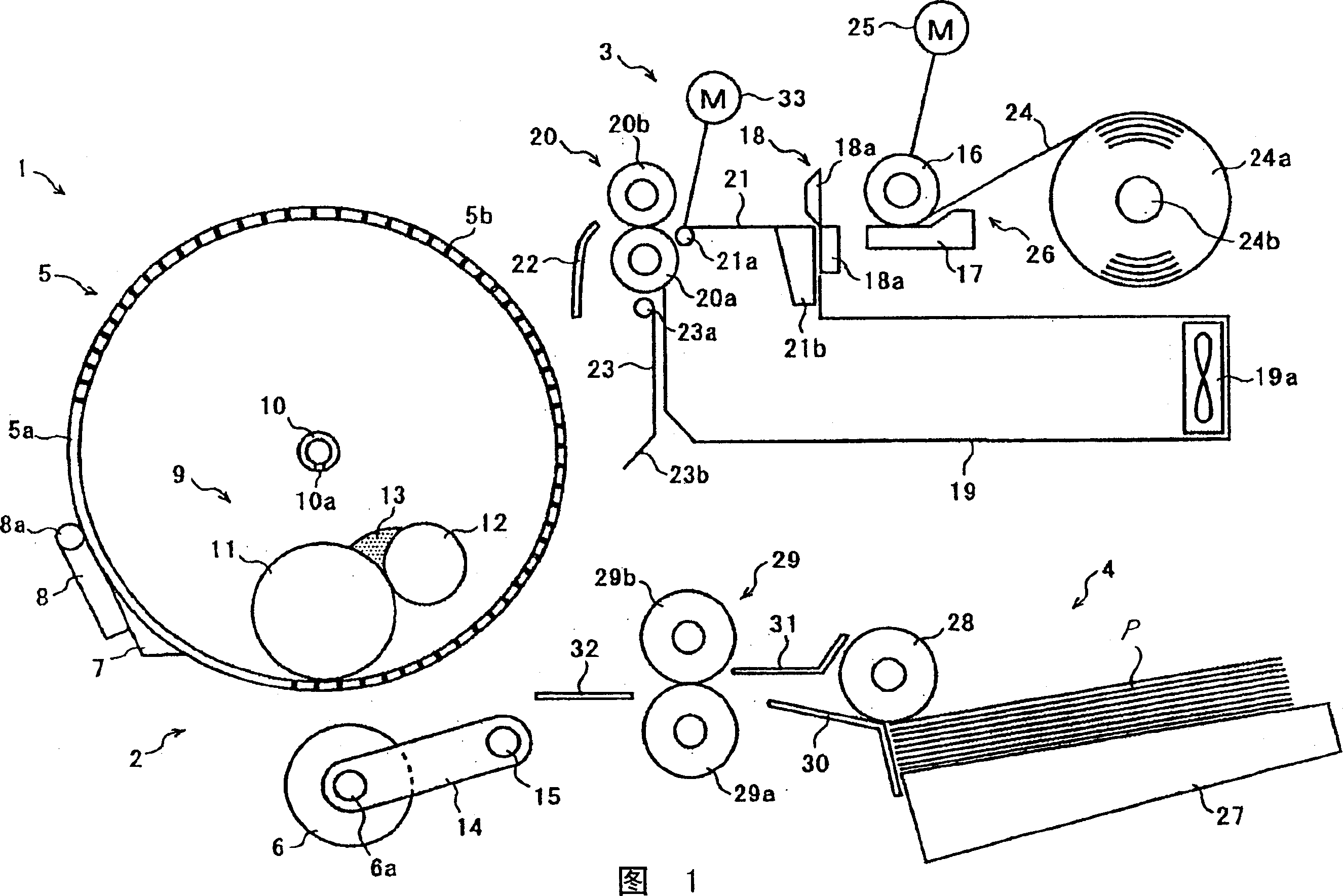

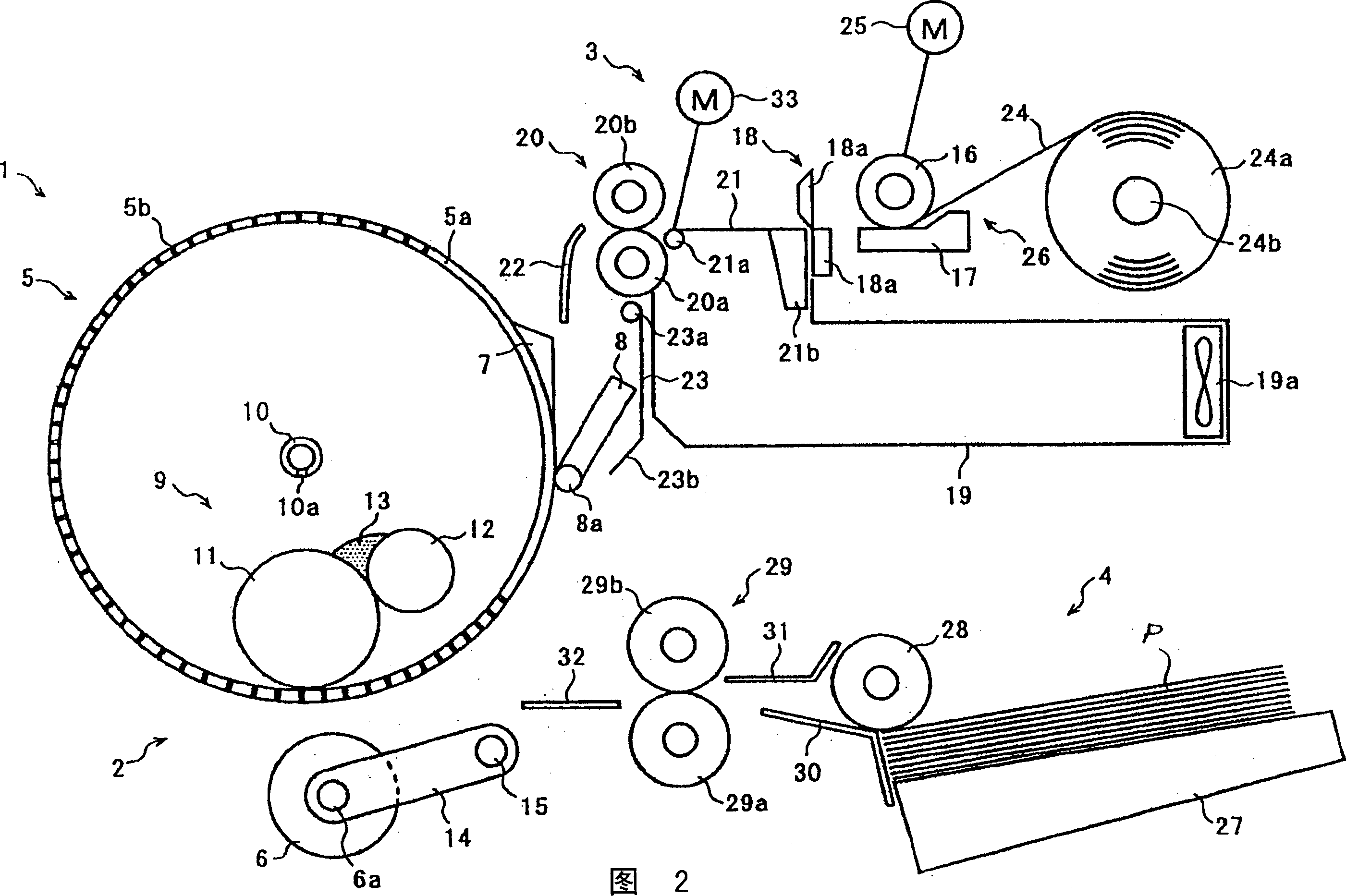

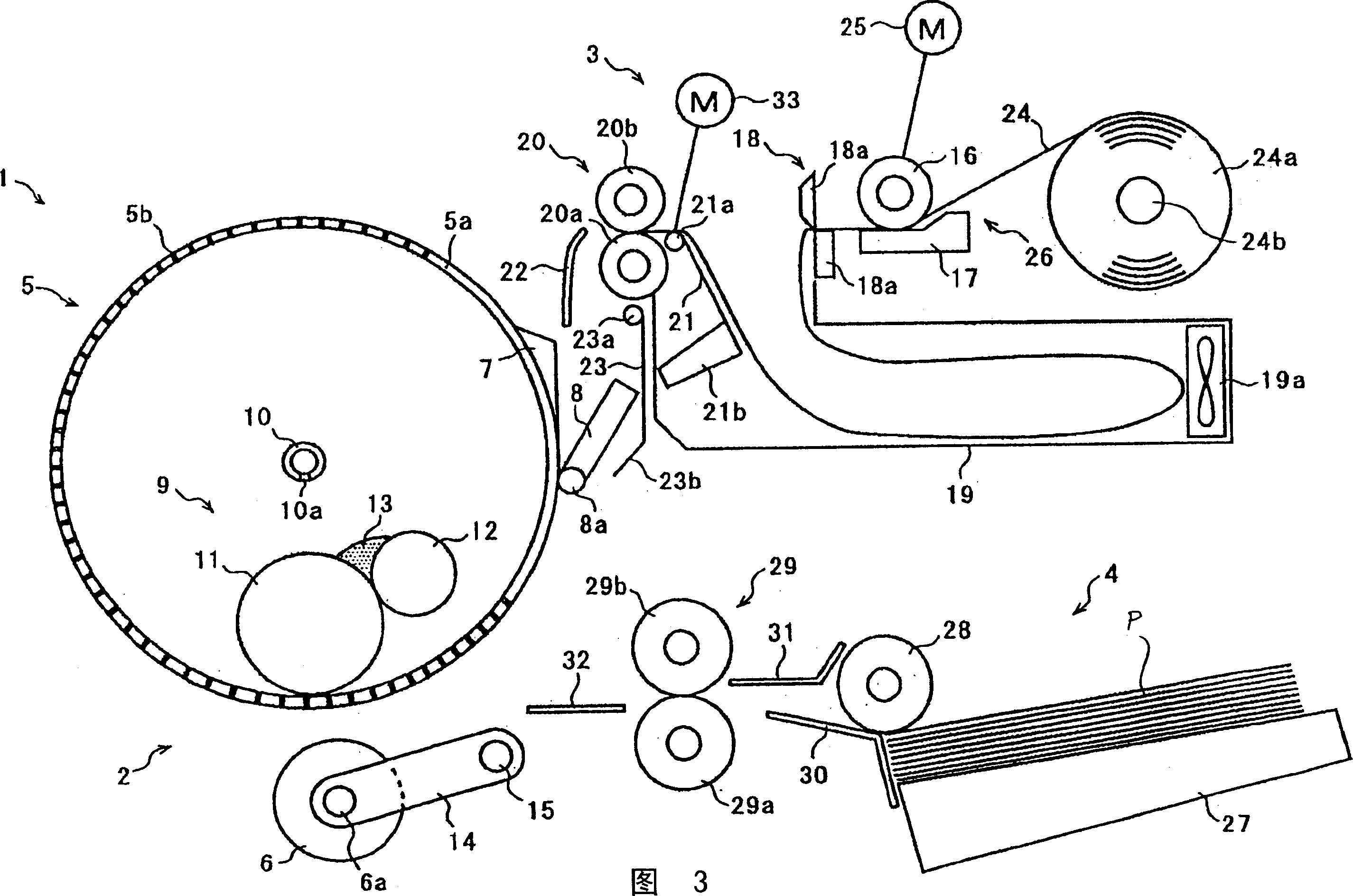

[0022] Referring to Figure 1 of the drawings, a stencil printing machine embodying the invention is shown and generally designated by the reference numeral 1 . As shown, the stencil printing machine 1 generally includes a printing section 2 , a master making and conveying section 3 , and a sheet feeding section 4 .

[0023] The printing section 2 comprises a printing drum 5 and a pressure roller 6 . The printing drum 5 is positioned at the approximate center of an unillustrated printing machine body, and is caused to rotate clockwise by an unillustrated printing drum driving device, as shown in FIG. 1 . The pressing roller 6 is movable toward and away from the printing drum 5 , and presses the sheet or recording medium P supplied from the sheet feeding section 4 against the printing drum 5 while moving toward the printing drum 5 .

[0024] The printing drum 5 has a pair of flanges at its axially opposite ends, although not specifically shown. The porous support 5a is fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com