Reduction gear box of electric machine

A reduction gear box and reduction box technology, applied in the direction of gear transmission, belt/chain/gear, electrical components, etc., can solve the problems of high manufacturing difficulty, affecting the smooth rotation of gears, complex structure, etc., and achieve manufacturing and assembly Simplicity and convenience, improved sealing performance, and simplified overall machine structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

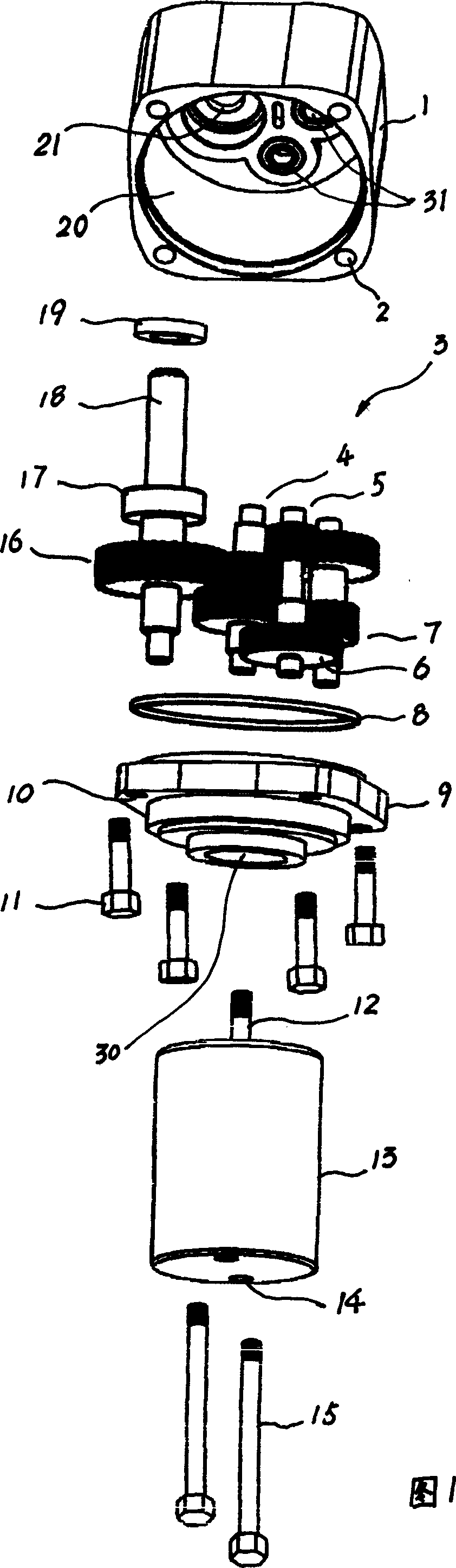

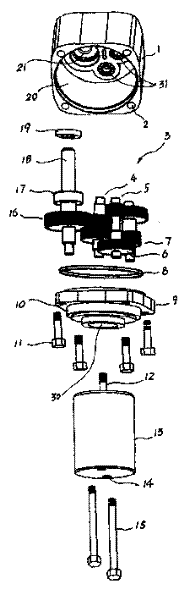

[0010] As shown in the figure, 1_reduction box, 2_threaded hole, 3_reduction mechanism, 4_the third transmission part of the deceleration mechanism, 5_the first transmission part of the deceleration mechanism, 6_the first transmission part gear of the deceleration mechanism, 7_the gear of the deceleration mechanism The second transmission part, 8_sealing ring, 9_end cover, 10_through hole, 11_screw, 12_motor drive shaft, 13_motor, 14_through hole, 15_screw, 16_fourth transmission part of the reduction mechanism, 17_bearing, 18_reduction mechanism output shaft, 19_ oil seal, 20_ airtight chamber, 21_ shaft seam, 30_ through hole, 31_ accommodating hole.

[0011] Referring to FIG. 1 , a motor reduction gearbox includes a motor 13 , a reduction box body 1 , an end cover 9 and a gear reduction mechanism 3 . The gear reduction mechanism 3 is a four-stage gear reduction mechanism, which is arranged in a closed chamber between the reduction box body 1 and the end cover 9 . The four-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com