Light mask and diffuse-reflecting board

A technology of diffuse reflector and photomask, which is applied to diffuse elements, optics, optical elements, etc., can solve the problems of high reflective brightness, difficult quality management, poor repeatability, etc., and achieve the effect of improving reflective brightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

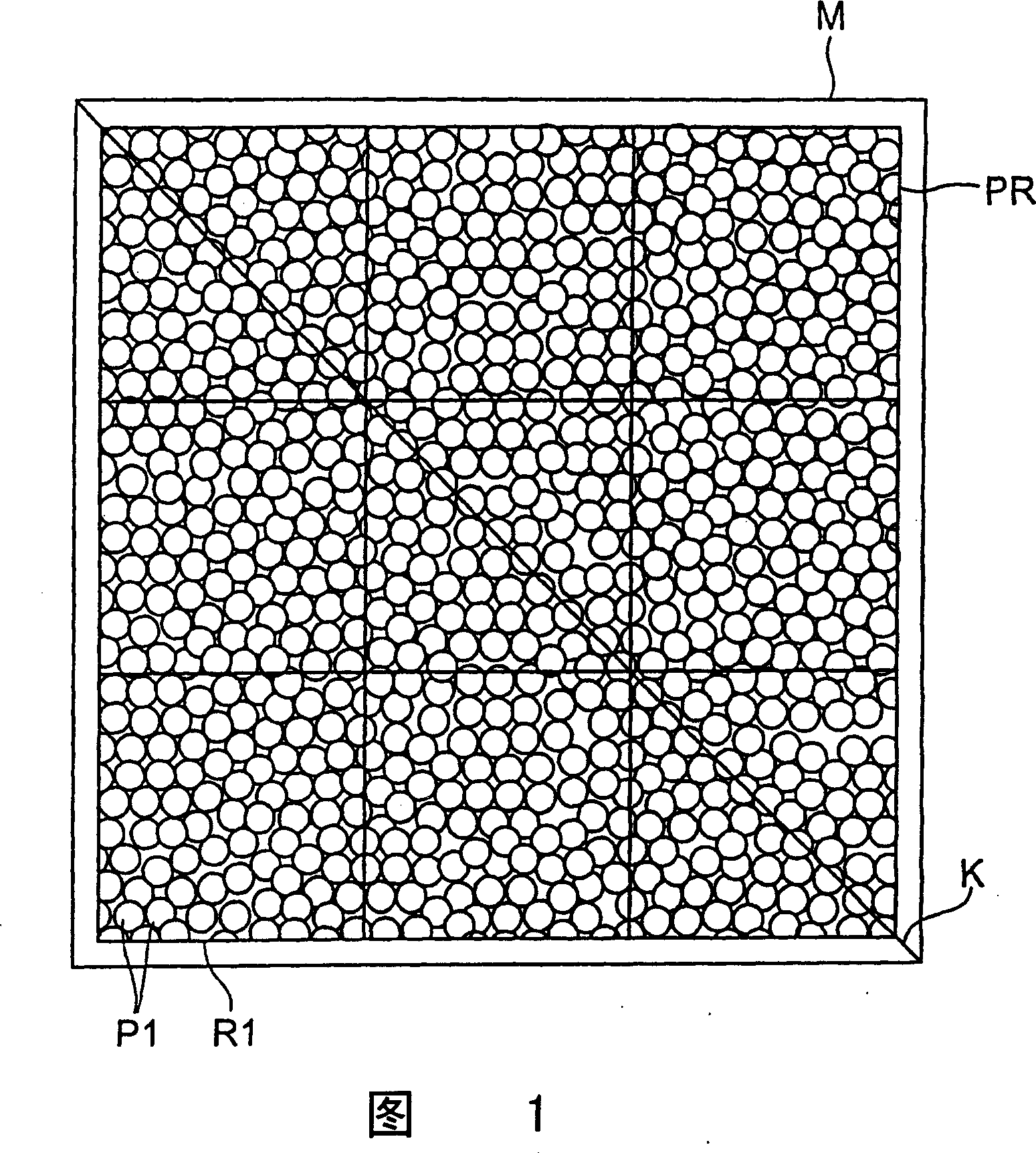

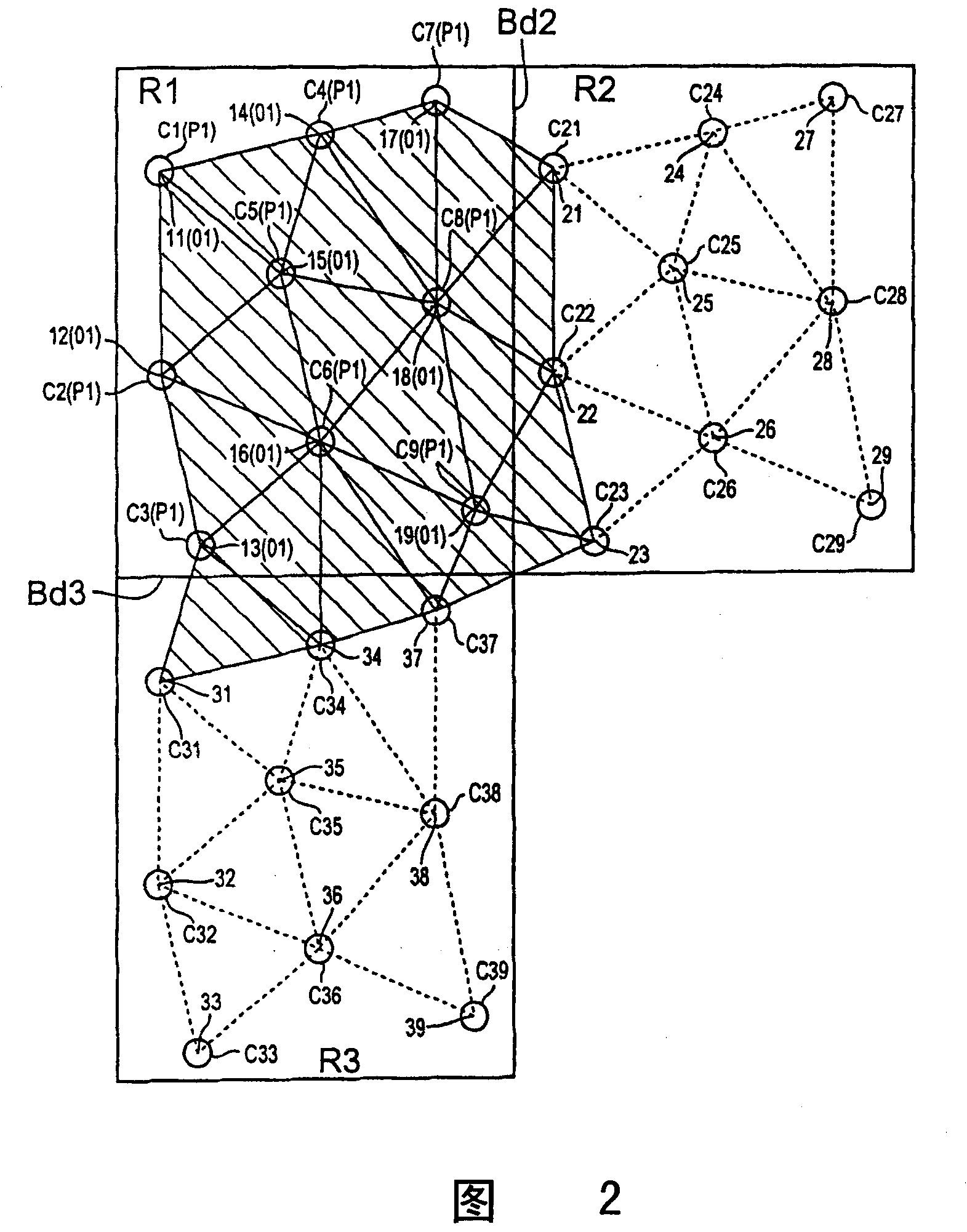

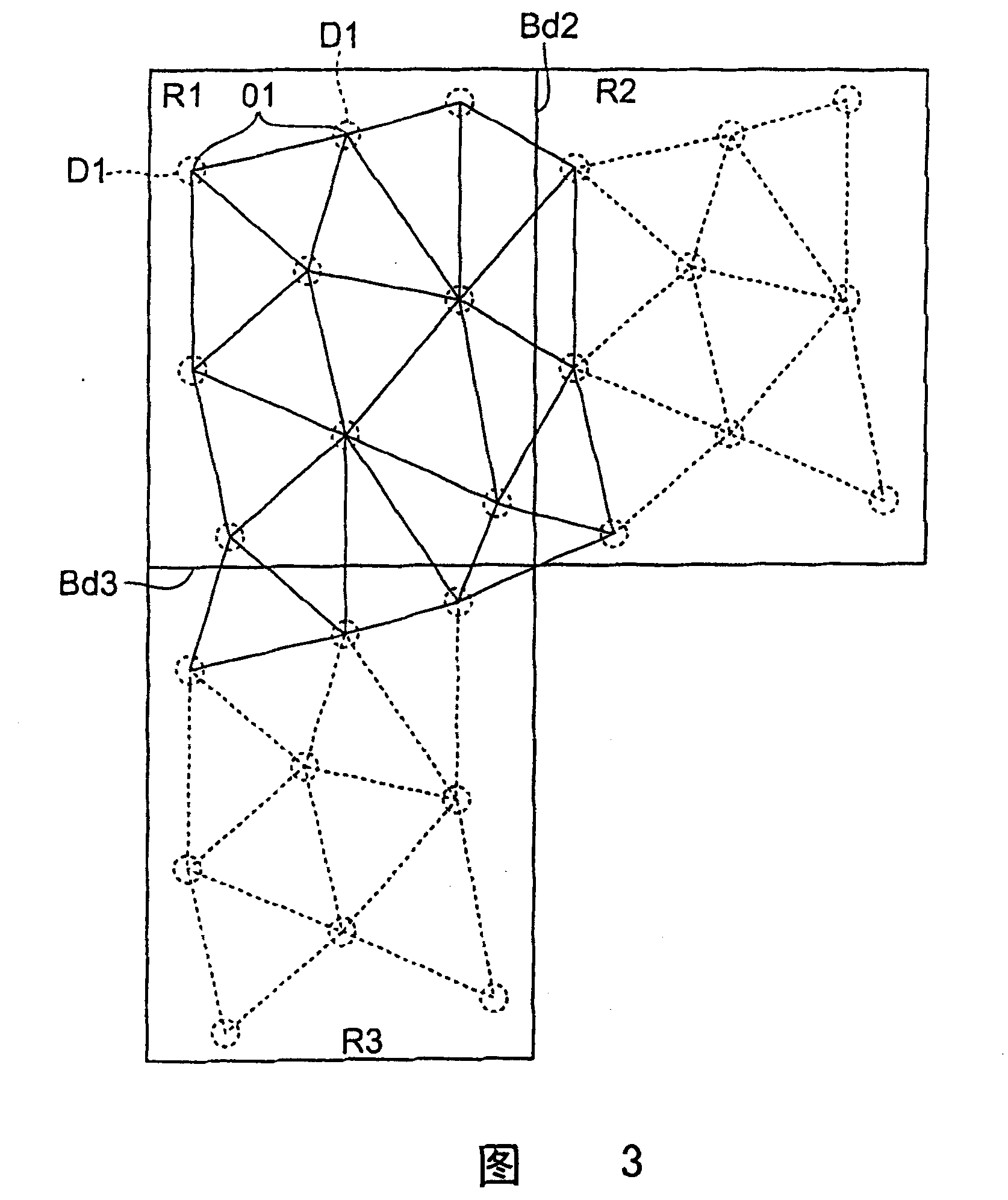

[0104] In the rectangular unit area (66 μm×198 μm) constituting the pattern area of the photomask, center points (73) of circular translucent portions with an outer diameter of 9 μm were arranged in a predetermined arrangement. The configuration is determined by the above method using random numbers. In the resulting configuration, the mean value A prescribed by the Dorronai triangle group (X) is 90 μm 2 , the value of B / A is 0.2. A filter plate with a diffuse reflection plate was fabricated using a photolithography technique realized by proximity exposure using this photomask. In addition, the unit area and the light-transmitting part on the photomask correspond to the unit pixel and the concave-convex part of the color filter.

[0105] First, on a cleaned glass substrate (Corning 1737) of 370×470×0.7 mm, a carbon black-added light-absorbing resist film (transmittance: 0.2 / μm) with a film thickness of 1.1 μm was applied. The resulting resist film was pre-baked on a hot p...

Embodiment 2)~( Embodiment 5

[0114] Within the scope of satisfying the above conditions (1) and (2), change the area of the rectangular unit area, the number of light-transmitting parts, the average value A and B / A, and make a photomask with the pattern area according to the present invention, Using this photomask, a diffuse reflection plate was produced in the same process as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com