Coloring Photosensitive Resin Composition Used For Forming Right Side Light Shielding Layer Of Display Device

A technology of photosensitive resin and light shielding layer, applied in the direction of photosensitive materials, optics, and opto-mechanical equipment used in opto-mechanical equipment, can solve the problems of poor productivity, time-consuming, large material consumption, etc. Effect of yellowing and coloring, improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0197] Preparation of colorant dispersion composition

[0198] By means of a sand mill, by mixing 60.51 g of TR-81 (available from HUNTMAN), 1.21 g of BYK-180 (available from BYK) as a dispersant, and 38.28 g of propylene glycol monomethyl ether acetate as a solvent / Dispersion was carried out for 2 hours to prepare a colorant dispersion composition of a colored photosensitive resin composition for forming a front light-shielding layer. Among them, TR-81 has 93% SiO 2 、Al 2 o 3 Surface treated TiO with organic materials 2 .

Embodiment 1

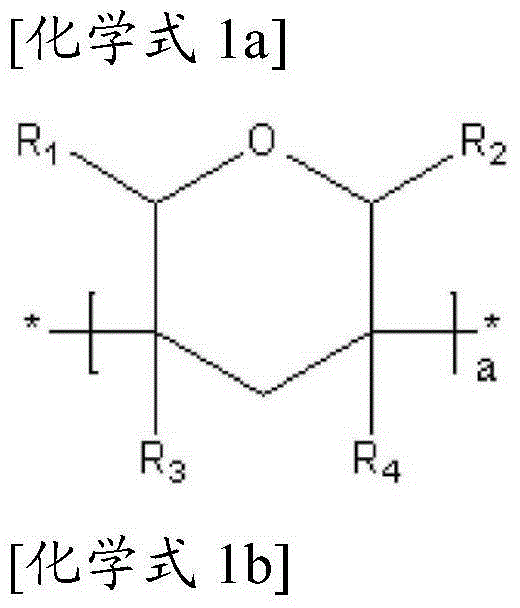

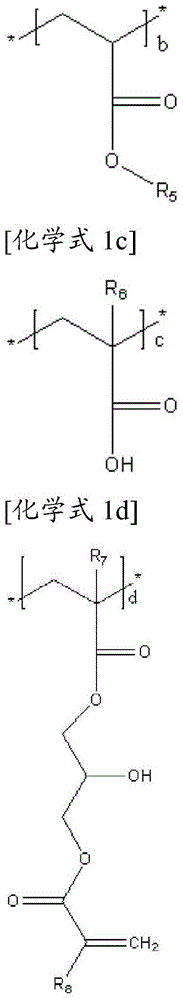

[0200] A colored photosensitive resin composition for forming a front light-shielding layer of a display device including an acrylic copolymer represented by Chemical Formula 8 in Table 1 below was prepared using composition ratios given in Table 1.

[0201]

[0202] The weight average molecular weight (Mw) of the compound of Chemical Formula 8 was about 10000, and the ratio of a':b':c':d' was 15:15:40:30.

[0203] [Table 1]

[0204]

Embodiment 2

[0206] Except for using the compound of chemical formula 8 whose ratio of a':b':c':d' is 20:15:40:25, the front light for forming the display device is prepared by the same method as the above-mentioned Example 1 A colored photosensitive resin composition for a shielding layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com