Switch

A switch and operating handle technology, applied in the field of switches, can solve the problems of not easy to visually see the operating position of fingers, difficult to distinguish the operating position, etc., and achieve the effect of beautifying the appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

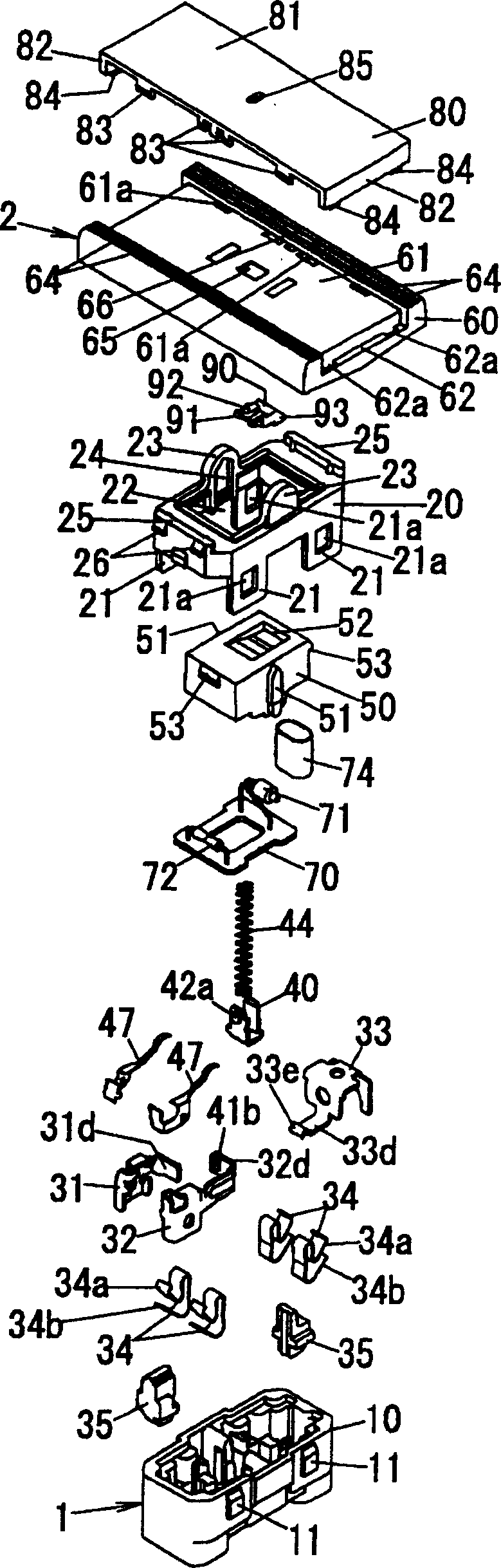

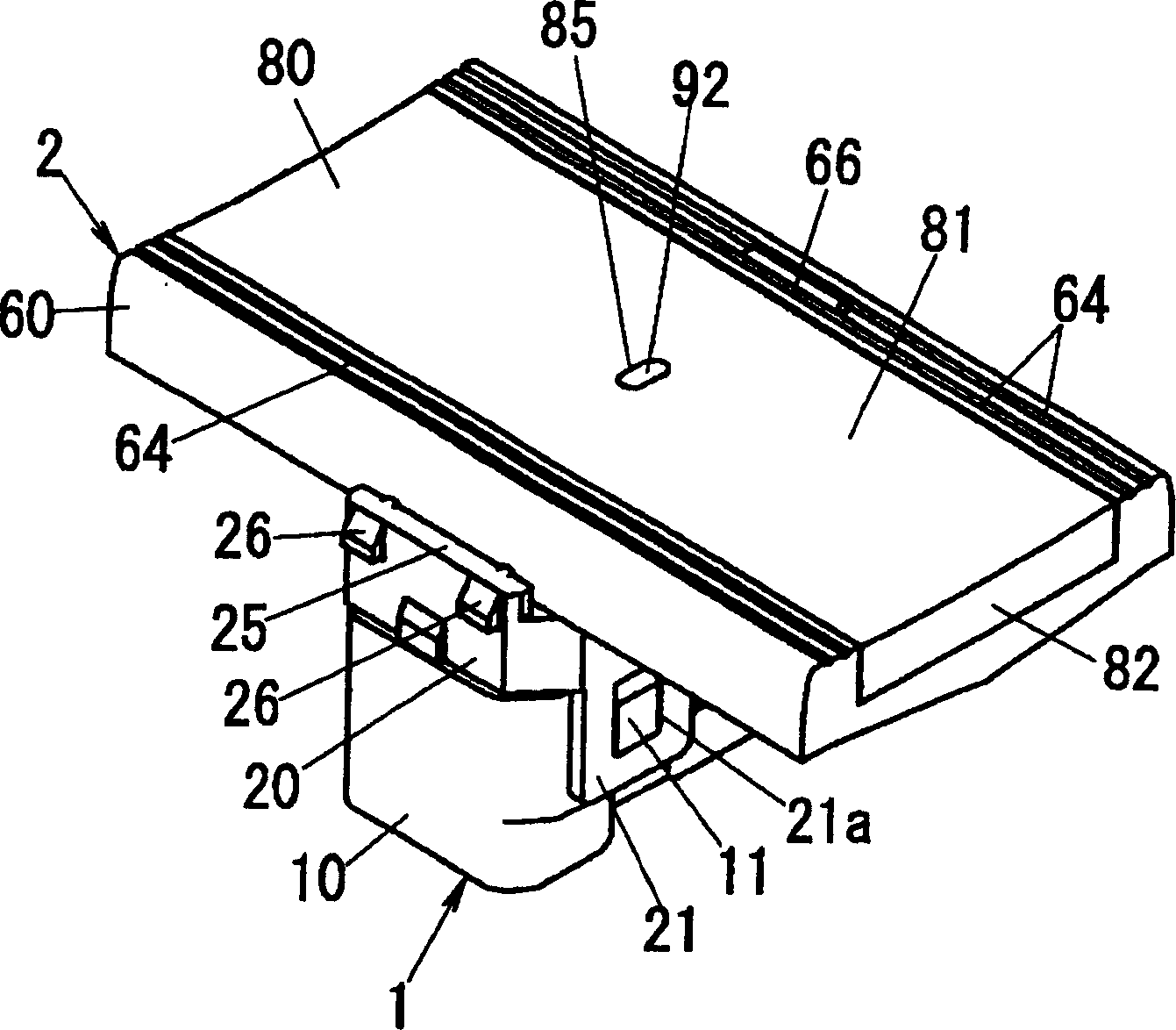

[0050] The switches of this embodiment, such as Figure 1 ~ Figure 4 As shown, there is a body 1 composed of a rectangular parallelepiped synthetic resin molded case 10 with an open front and a synthetic resin molded cover 20 formed in a rectangular frame shape and joined to the front side of the case 10 . On the two outer sides in the width direction (transverse direction) of the housing 10, a pair of mounting protrusions 11 are projected at intervals in the longitudinal direction of the housing 10, and a mounting tongue 21 is extended backward from the rear end edge of the cover 20. , engage the fitting protrusion 11 in the fitting hole 21 a provided on the fitting tongue 21 , and thus combine the case 10 and the cover 20 .

[0051] Regarding the housing 10, at one end in the longitudinal direction ( Figure 4 The left end of the center) accommodates two terminal boards 31, 32, and the other end ( Figure 4 A terminal board 33 is accommodated in the right end portion of th...

Embodiment 2

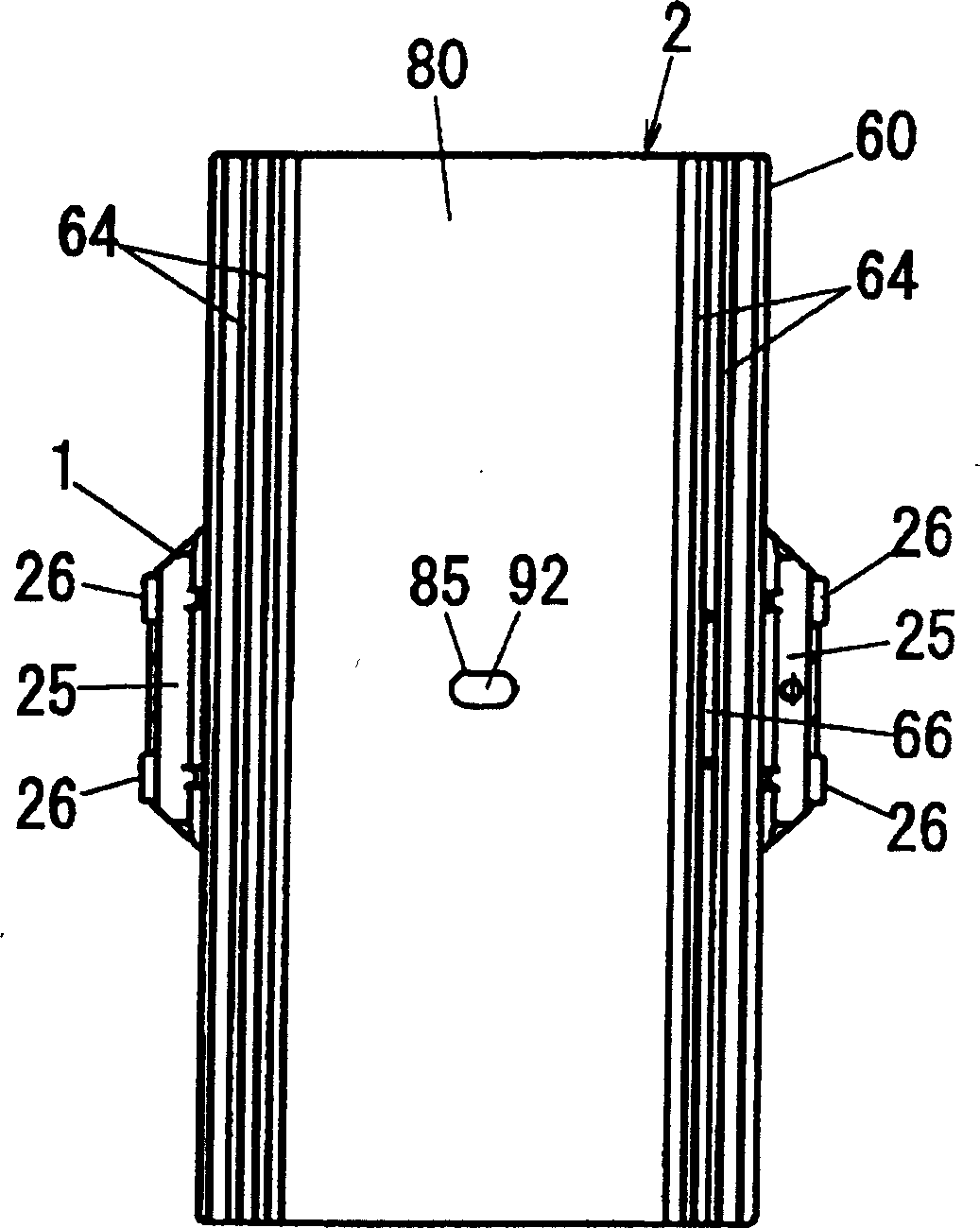

[0079] The basic structure of the switch of this embodiment is roughly the same as that of Embodiment 1, as Figure 12 As shown, the dimensions of the operating handle body 60 and the handle cover 80 are different from those of the first embodiment. That is, in this embodiment, the size of the operating handle 2 is different from that of the operating handle 2 for one described in the first embodiment. In addition, the same code|symbol is attached|subjected to the same component as Example 1, and description is abbreviate|omitted.

[0080]The operating handle 2 of this embodiment is called the operating handle 2 for two because the operating handle main body 60 is formed to cover the size of the two window holes 120a of the mounting frame or the plate frame 120 . That is, the size of the operating handle 2 for two is the same as that of the operating handle 2 for one in the direction along the widthwise direction of the window hole 120a of the plate frame 120, and the dimensi...

Embodiment 3

[0082] The basic structure of the switch of this embodiment is roughly the same as that of Embodiment 1, as Figure 22 and 23 As shown in (a), the dimensions of the operating handle main body 60 and the handle cover 80 are different from those of the first embodiment. That is, in this embodiment, the size of the operating handle 2 is different from that of the operating handle 2 for one described in the first embodiment. In addition, the same code|symbol is attached|subjected to the same component as Example 1, and description is abbreviate|omitted.

[0083] The operating handle 2 of this embodiment is called a three-purpose operating handle 2 because the operating handle main body 60 is formed with the size of the three window holes 120a covering the installation frame or the plate frame 120 . That is, the size of the operating handle 2 for three is the same as that of the operating handle 2 for one in the direction along the widthwise direction of the window hole 120a of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com