Manufacturing method of large caliber direct through plastic pipe joint

A manufacturing method and technology of plastic pipes, which are applied in the field of manufacturing plastic pipe joints, can solve the problems that straight-through plastic pipe joints cannot be matched with large-diameter plastic winding pipes, etc., and achieve the effects of saving equipment investment, high economic benefits and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

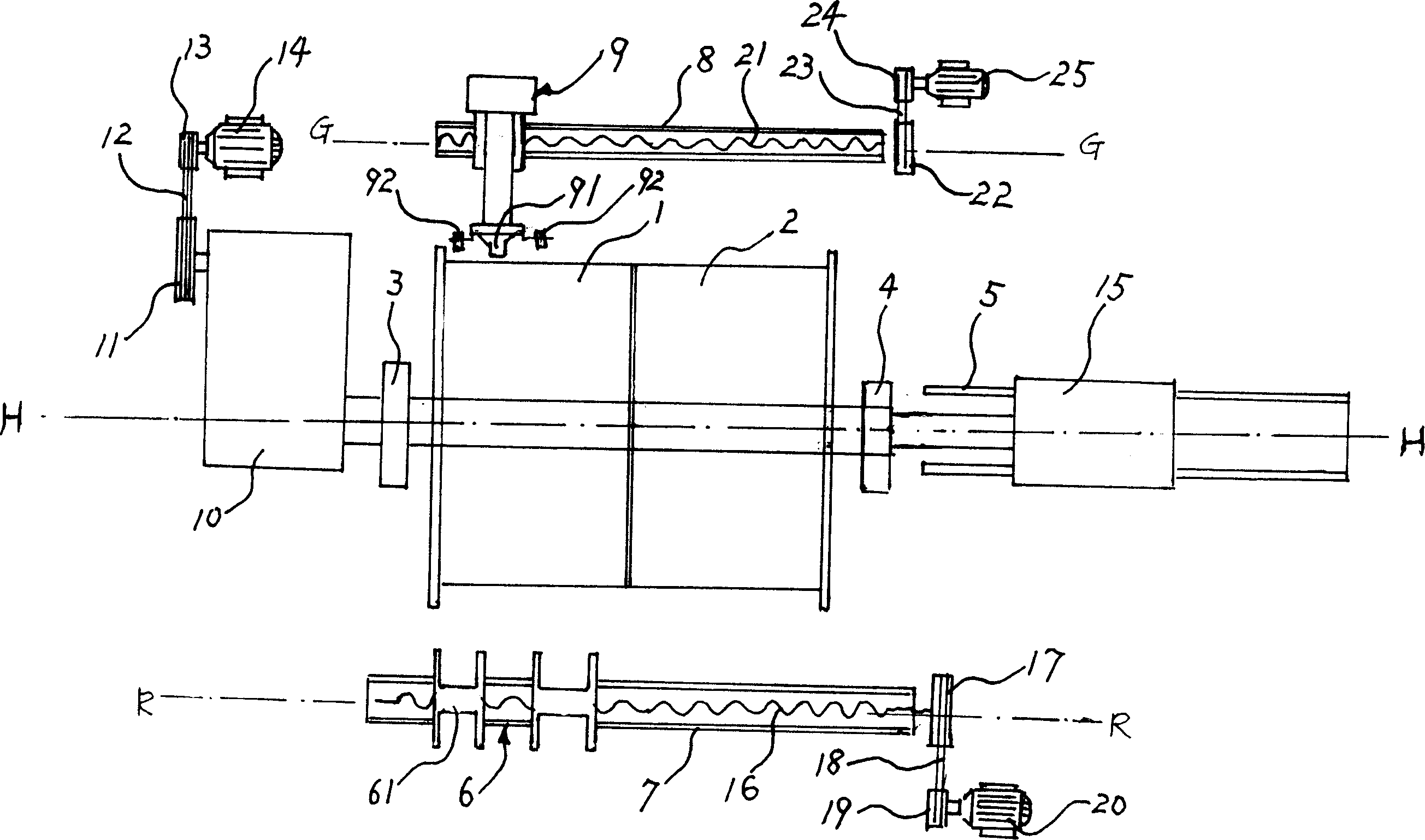

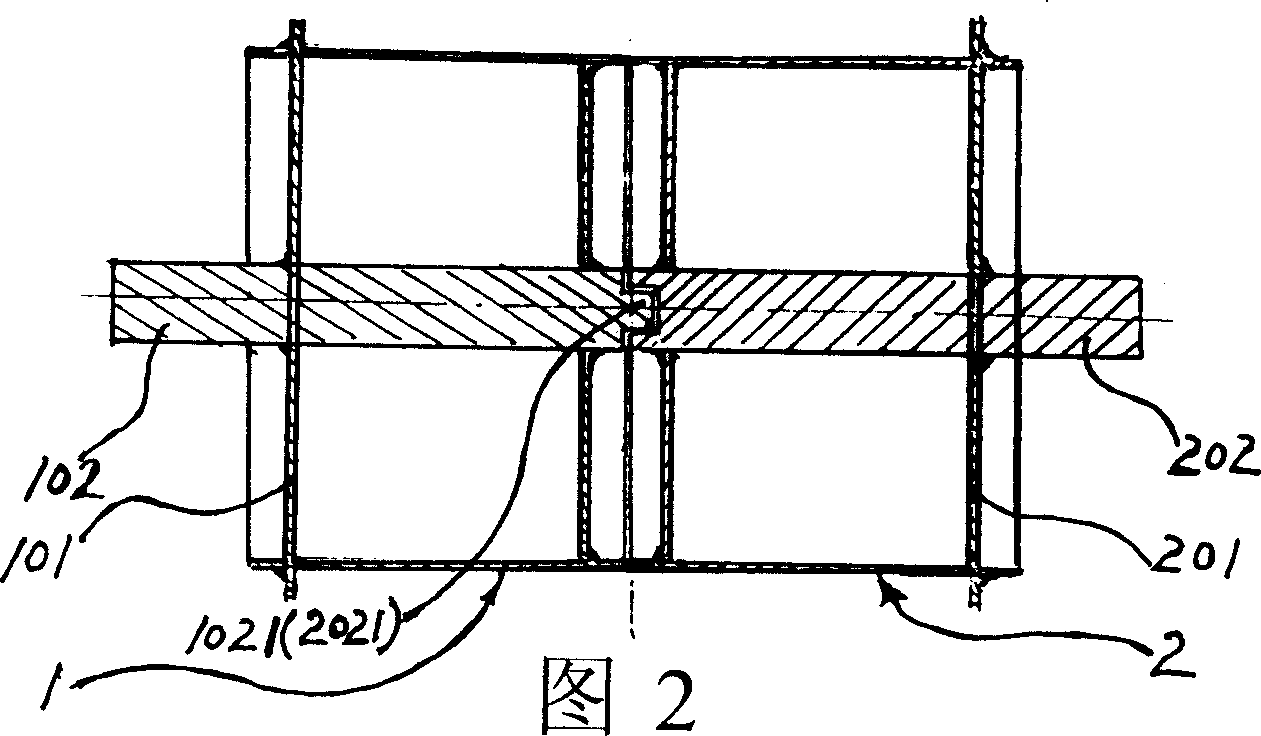

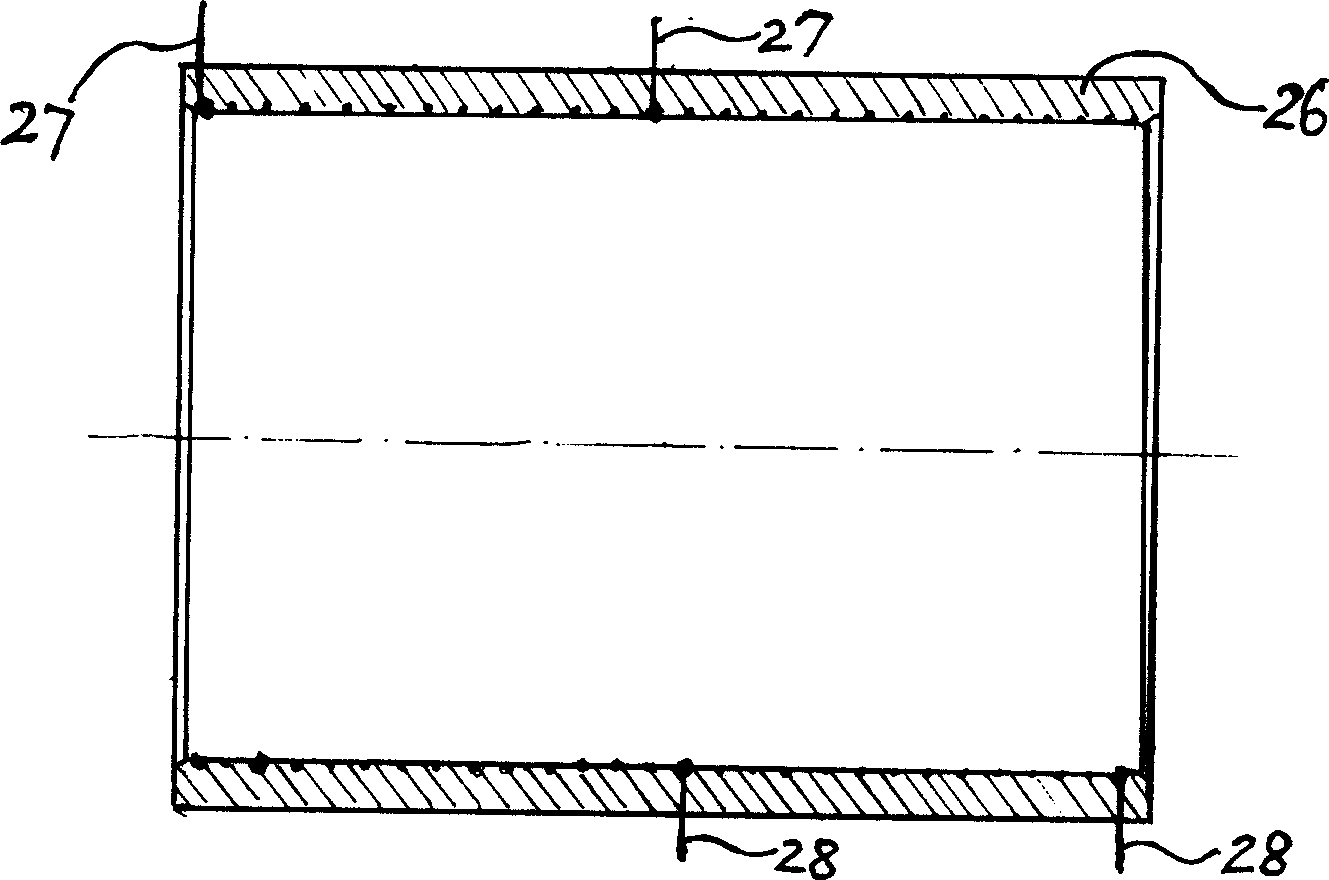

[0018] see figure 1 with Figure 2. The method for manufacturing large-diameter straight-through plastic pipe joints according to the present invention has the following solution: ①Take two forming molds 1 and 2 whose outer diameters are equal to the outer diameters of the connected pipes, which can be butted into one and can be disassembled, The two ends of the two butted forming molds 1 and 2 are respectively equipped with clamps 3 and 4 that can be rotated forward and reverse to drive the two molded molds 1 and 2 to rotate correspondingly, and one of the clamps 4 is installed on the guide rail 5 And it can move back and forth along the guide rail 5; on one side of the two forming molds 1 and 2, there is a winding machine 6 equipped with a winding reel 61, the winding reel 61 is equipped with resistance wire, and the winding machine 6 is installed on the guide rail 7 And can move back and forth along guide rail 7; Be provided with a plastic extruder 9 that is installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com