Fuel cell and its mfg. method, electronic machine and automobile

一种燃料电池、制造方法的技术,应用在燃料电池、燃料电池的零部件、固体电解质燃料电池等方向,能够解决制造成本增高、使用量增加、工序多等问题,达到低成本、减少使用量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Next, the fuel cell of the present invention, its manufacturing method, electronic equipment, and automobiles will be described in detail.

[0046] 1) Fuel cells

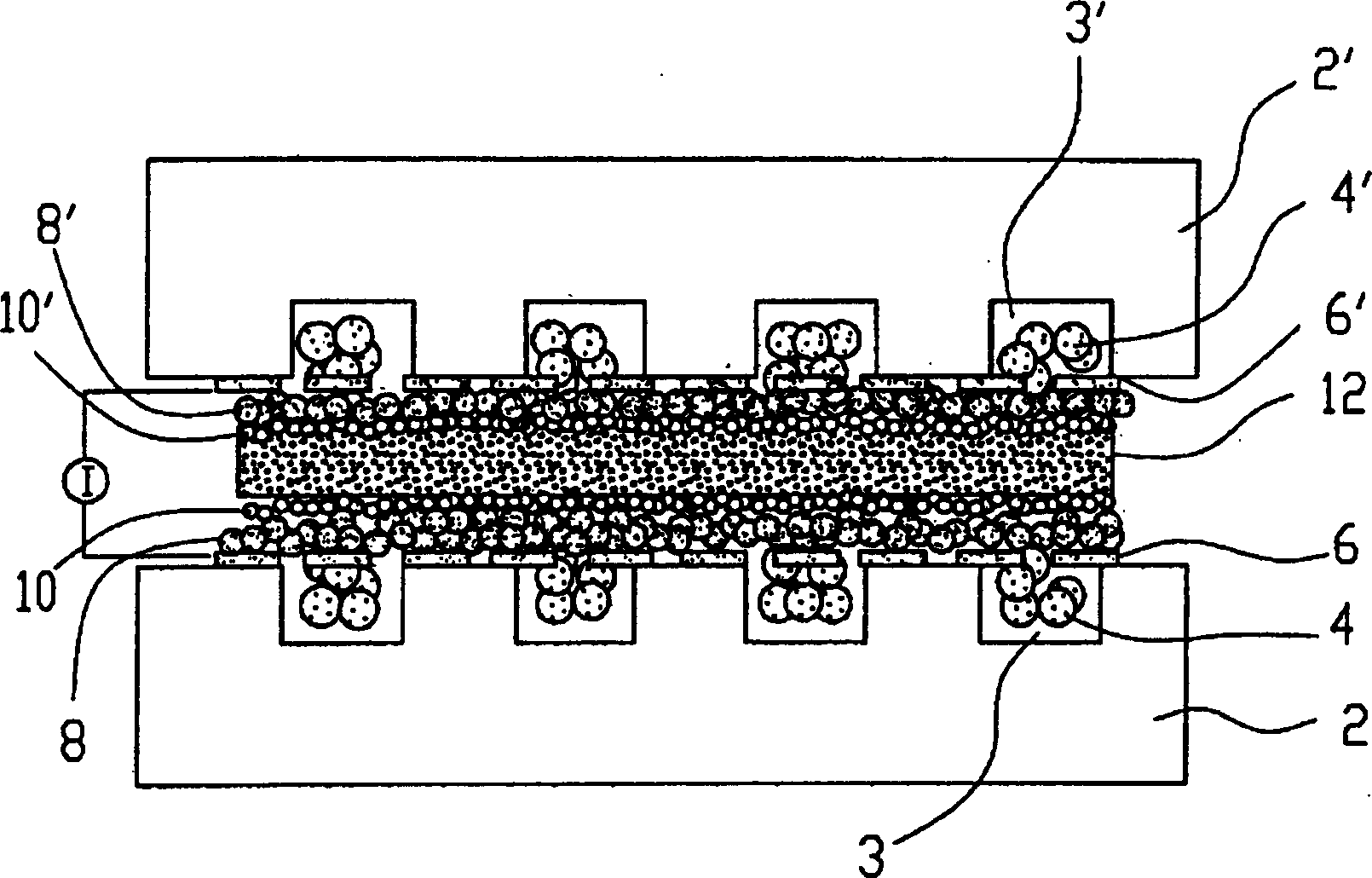

[0047] figure 1 An end view showing the fuel cell of the present invention. figure 1 The fuel cell shown is composed of the following parts starting from the lower side in the figure, that is, a first substrate 2, a first gas flow channel 3 formed on the second substrate 2, and a first gas flow channel housed in the first gas flow channel. 3, the first support member 4, the first collector layer 6 formed on the first substrate 2 and the first support member 4, the first gas diffusion layer 8, and the first reactant formed on the first gas diffusion layer 8 layer 10, electrolyte membrane 12, second reaction layer 10', second gas diffusion layer 8', second collector layer 6', second gas channel 3', 2nd support member 4', 2nd board|substrate 2'.

[0048] The type of the fuel cell of the present invention is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com