Method for reducing height error and out-beat of main shaft motor and thin type main shaft motor

A spindle motor and height error technology, which is applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve the problems of spindle motor height accuracy, heavy work and time-consuming, bearing surface deflection, etc., to save cost and time, eliminate The effect of assembly error and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

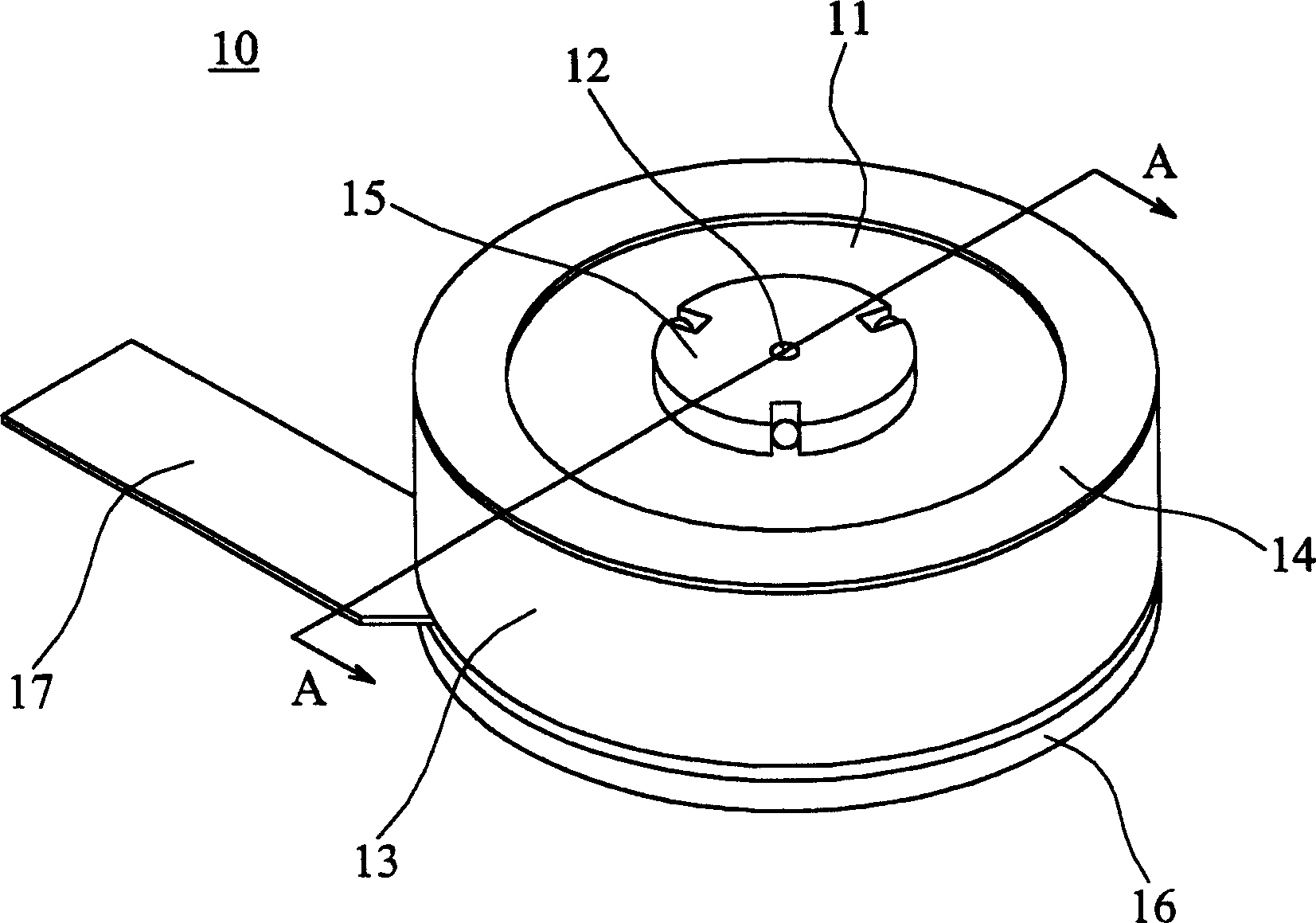

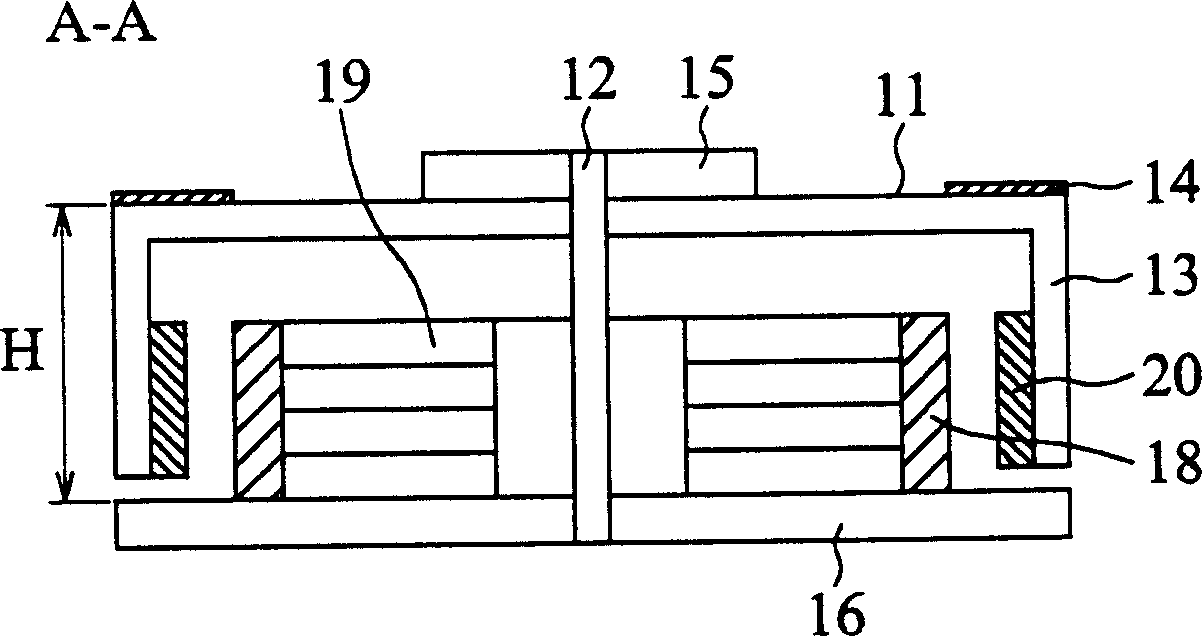

[0051] As mentioned above, in terms of a thin spindle motor, usually no separate bearing plate is assembled on the motor, but the surface of the rotor of the motor is directly used as the bearing surface. Therefore, the method for reducing the height error and deflection of the spindle motor provided by the present invention will be described below by taking a thin spindle motor as an example.

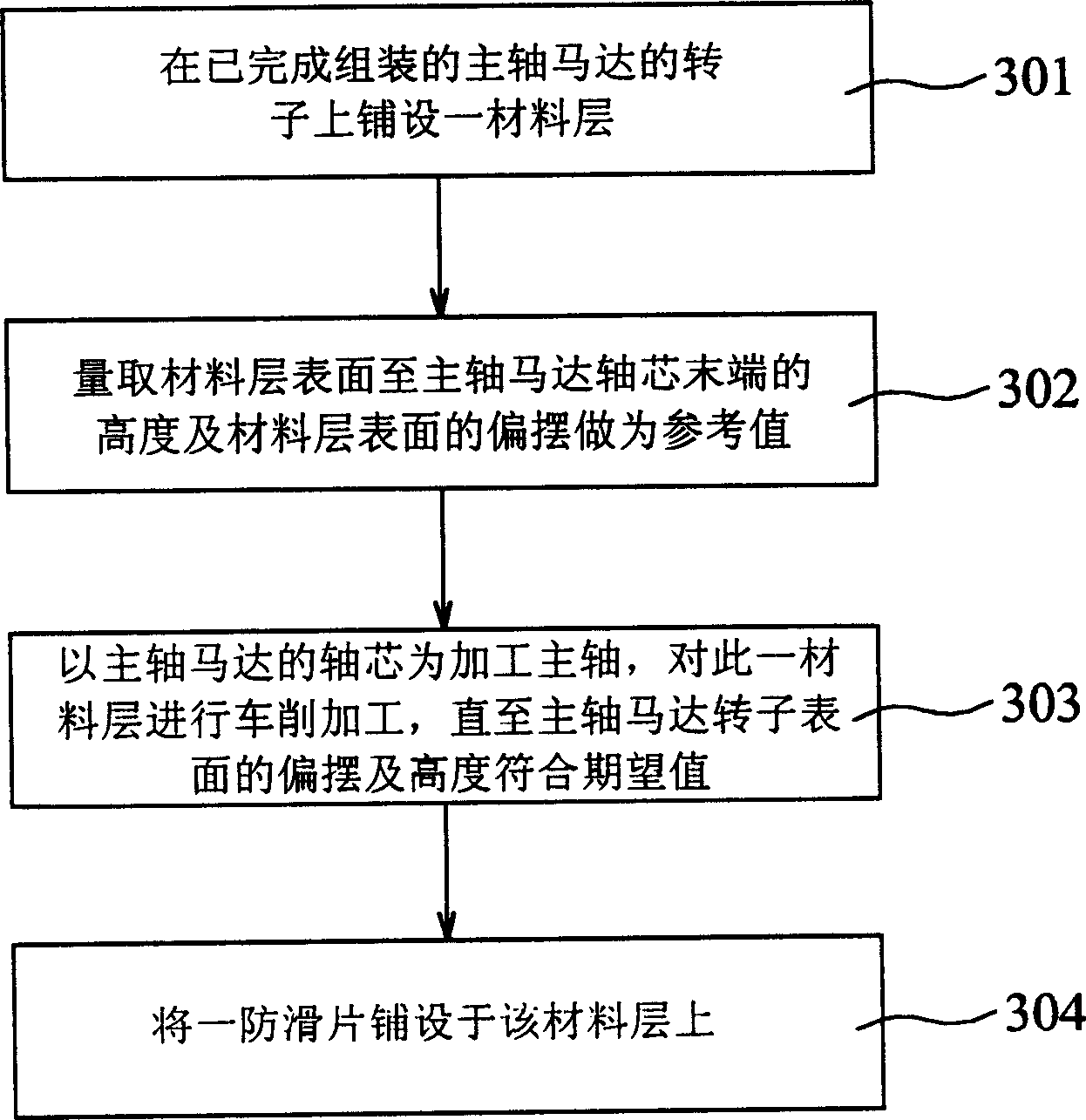

[0052] See image 3, the method provided in an embodiment of the present invention includes implementing steps 301-304. First, step 301 is to lay a material layer on a bearing surface of the assembled spindle motor; here, a polymer material layer is laid on the surface of the rotor ( Figure 4 200), for example, a material selected from polycarbonate (Polycarbonate; PC) and polyethylene terephthalate (Polyethylene terephthalate; PET). Next, step 302 is to measure the height from the surface of the polymer material layer to the end of the shaft core of the spindle motor and the deflec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com