Stud welding gun with stud detection system

A technology of studs and detection circuits, which is applied in the direction of welding equipment, measuring electricity, measuring devices, etc., and can solve problems such as delayed setting of studs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments described below are merely exemplary in nature and do not limit the invention and its applications or uses.

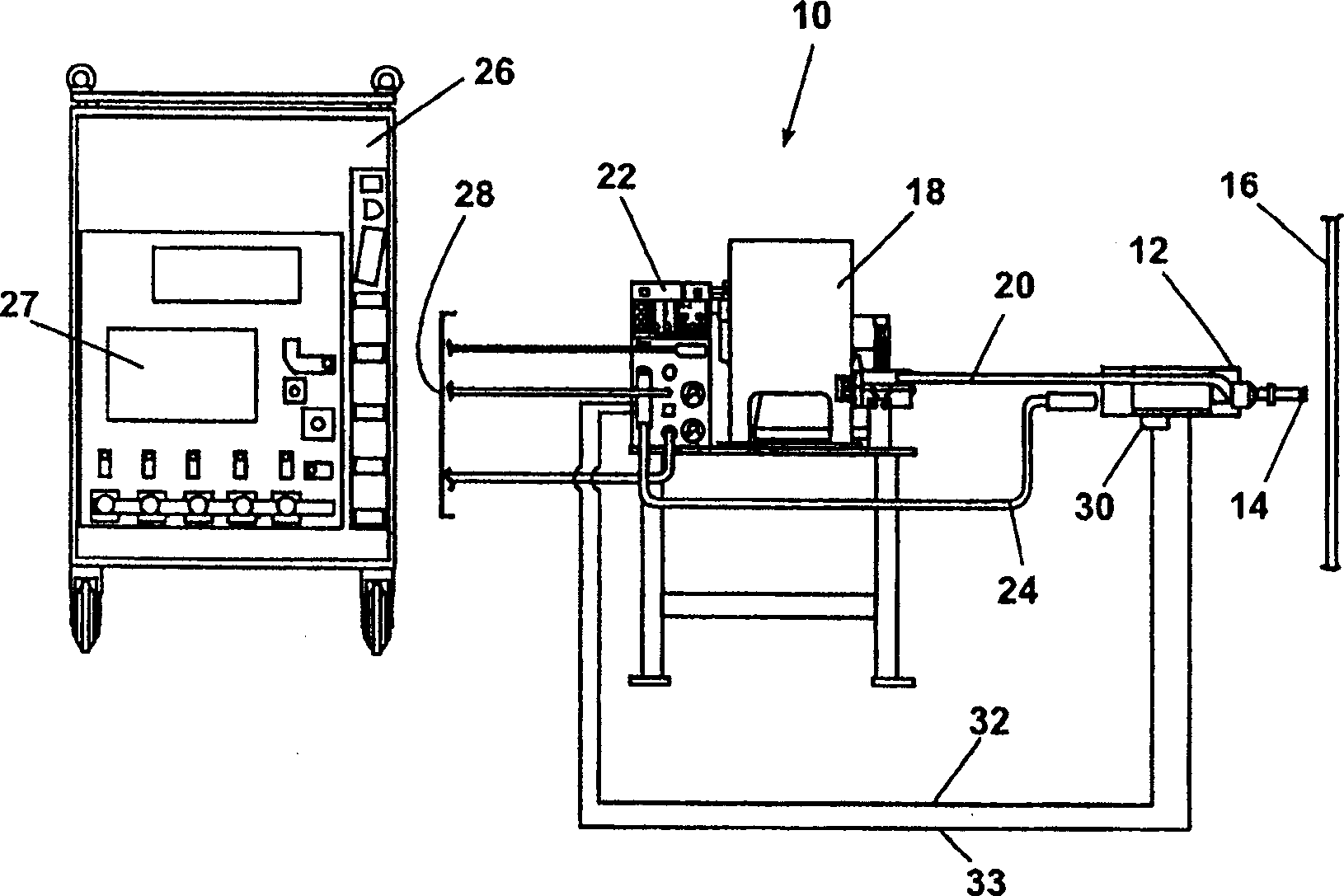

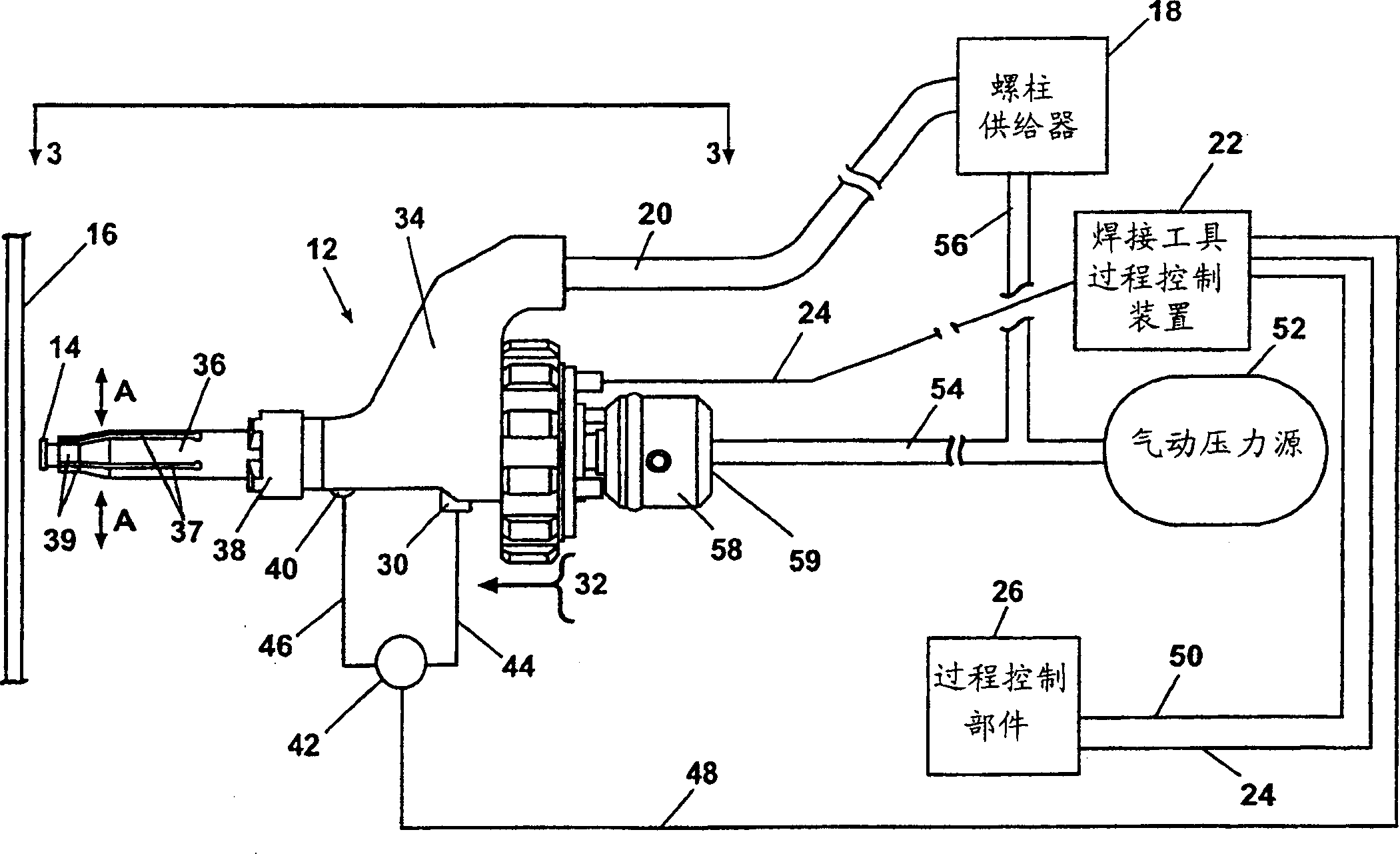

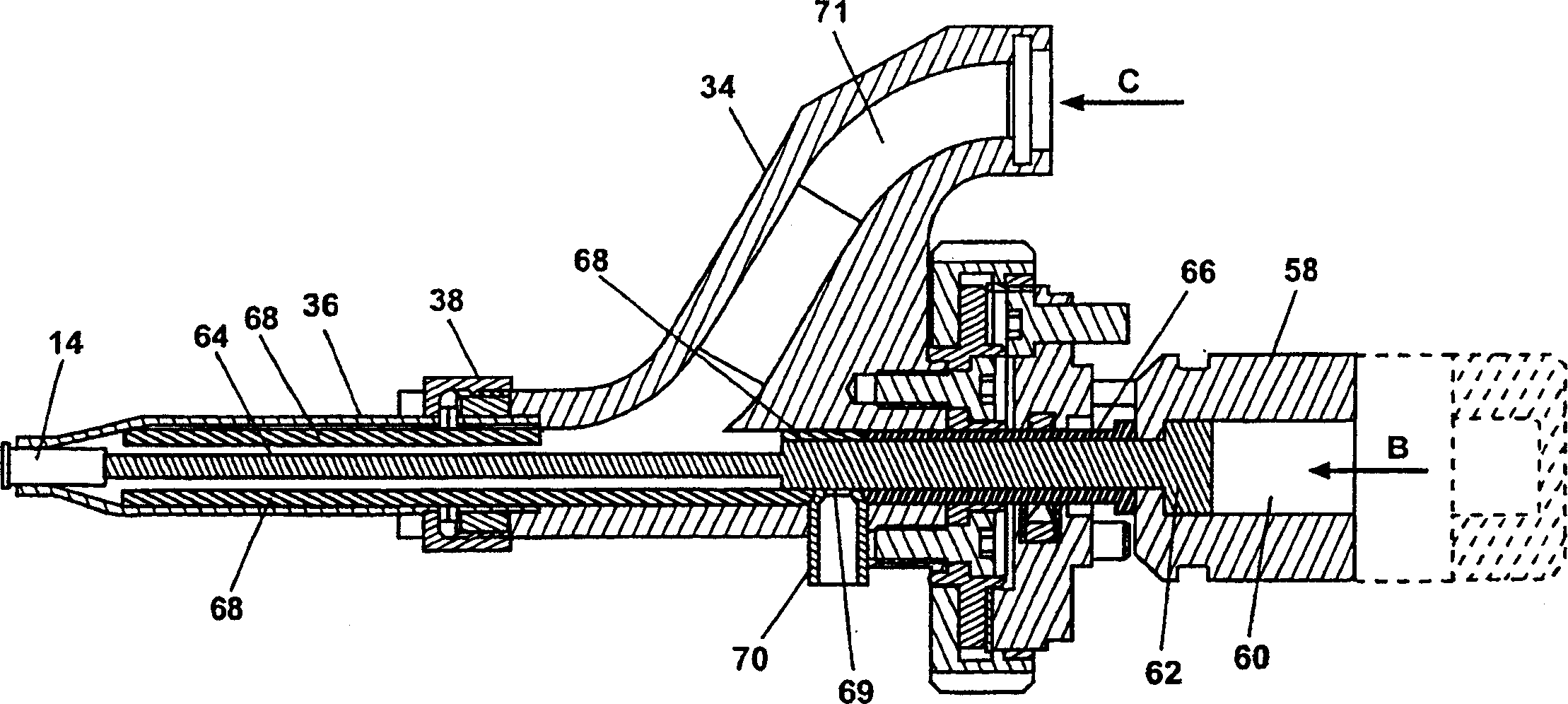

[0026] figure 1 A stud welding gun representing a preferred embodiment of the present invention. The stud inspection system 10 includes a stud welding gun 12 that holds a stud 14 in place for welding to a workpiece 16 . The workpiece 16 can be imagined to be a thin sheet steel automotive panel. Each stud 14 is supplied to the stud welding gun 12 via a stud supply feeder 18 and a pneumatic tube 20 . The welding tool process control unit 22 is connected to the stud welding gun 12 via a welding current supply line 24 . The welding tool process control device 22 is electrically connected on the supply side to the process control component 26 via a control line 28 . The process control component 26 also includes a welding current source 27 . The process control component 26 is connected to the conductive member 30 of the stud welding gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com