Method for preparing laser label on reflective materials

A processing method and technology for reflective materials, applied in laser welding equipment, metal processing equipment, optics, etc., can solve the problems of destroying the reflective material matrix, low difficulty, inconvenience, etc., and achieve the effect of good optical effect and high imitation difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

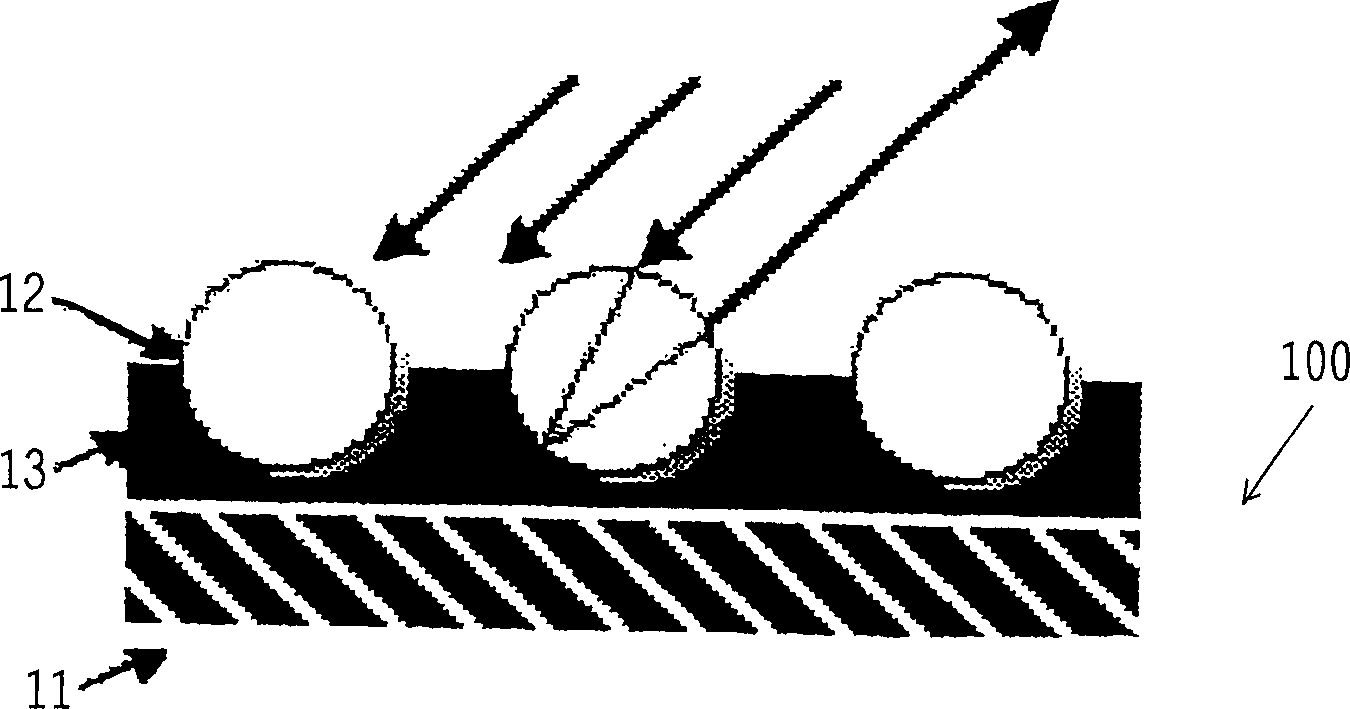

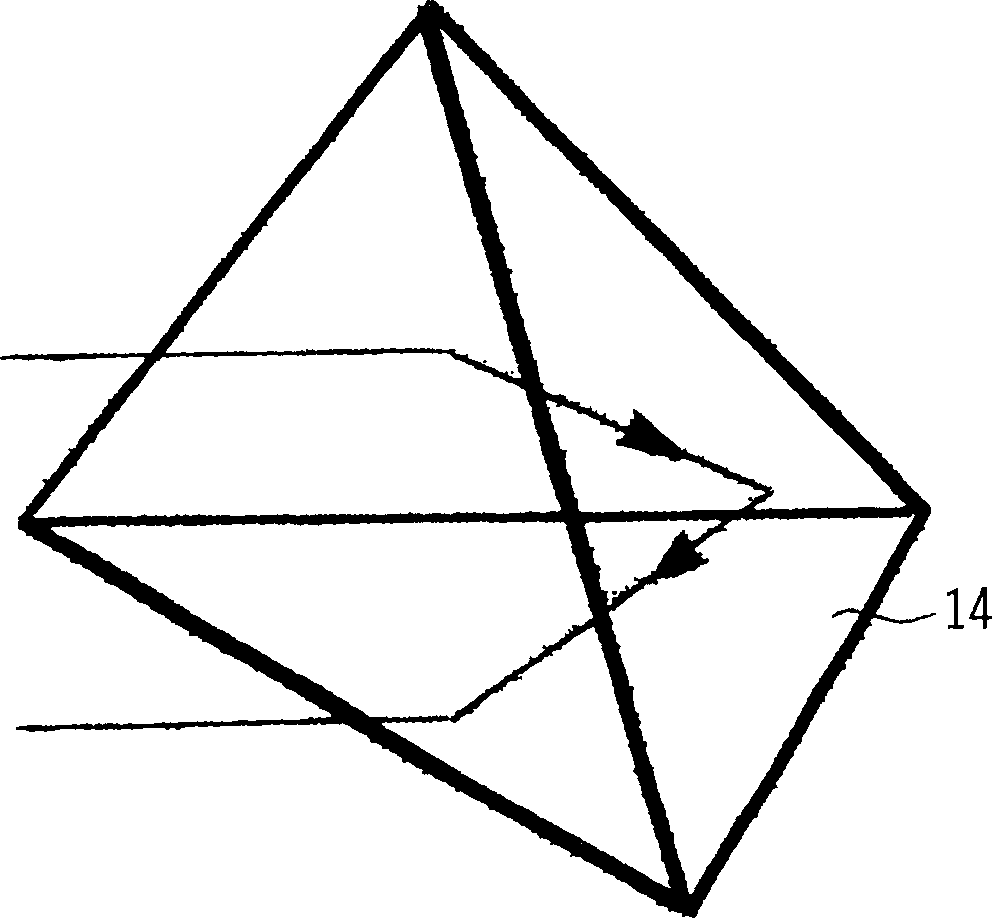

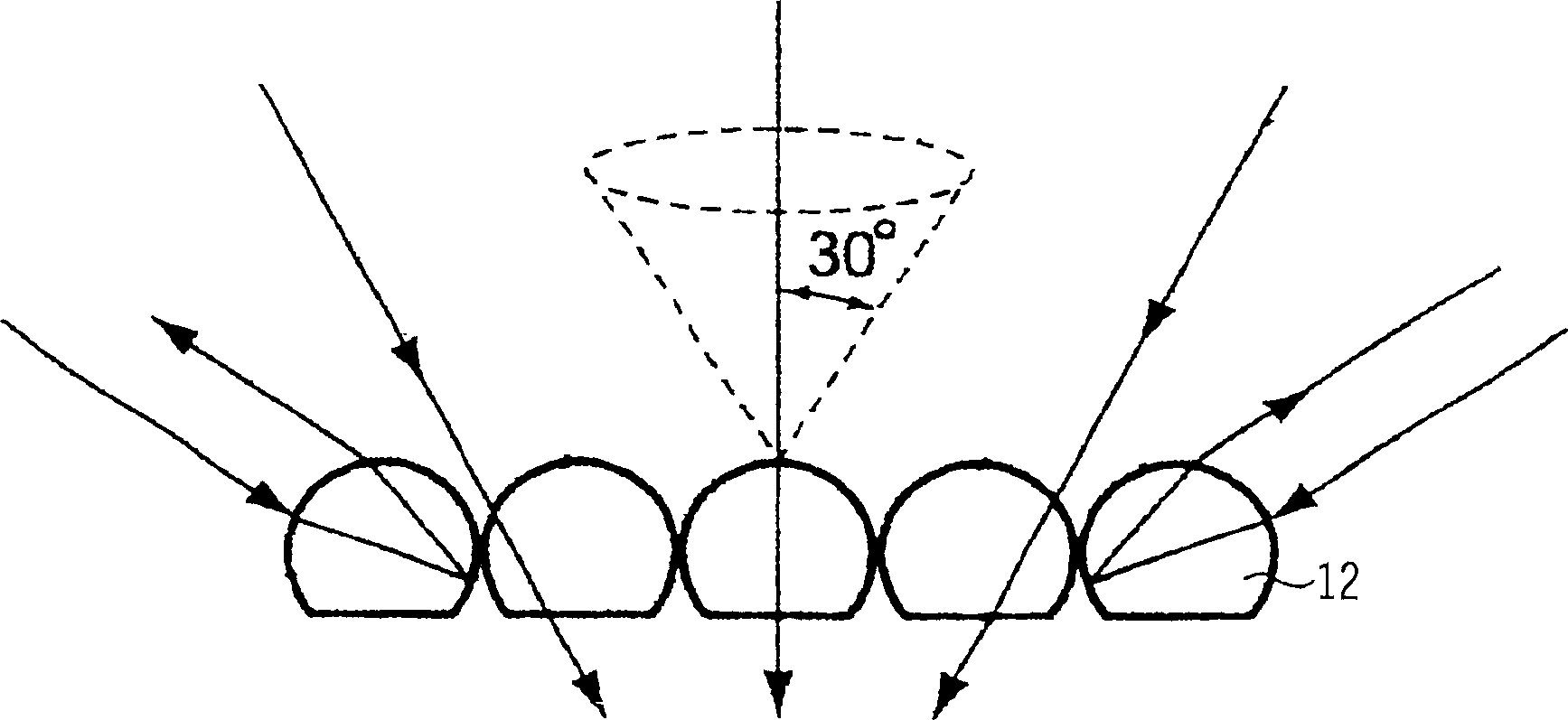

[0030] Figure 4 It is a schematic diagram when the laser beam burns the mark on the reflective material according to the method of the present invention. Figure 4 Although it is a spherical reflector 12 in the picture, it is exactly the same for the effect of the reflector 14 of polyhedron shape. The laser beam used can irradiate at least an area larger than a spherical surface of the reflector. Figure 4 The processing laser beam of the present invention shown in is not irradiated to the reflector 12 along the direction of the bottom of the vertical reflector, but irradiates the reflector 12 with a certain angle, that is, any angle of incidence between 10° and 80° The first incident surface on the upper part makes the surface produce tiny gasification hairs, so that the incident light is scattered or refracted in multiple directions, so that it will not be reflected in the incident direction; when viewed along the direction of this incident angle, the gas The hairy surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com