Optical monitor module

A monitor and optical technology, applied in the field of optical monitor components, can solve the problems of increasing light loss, large space, occupation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

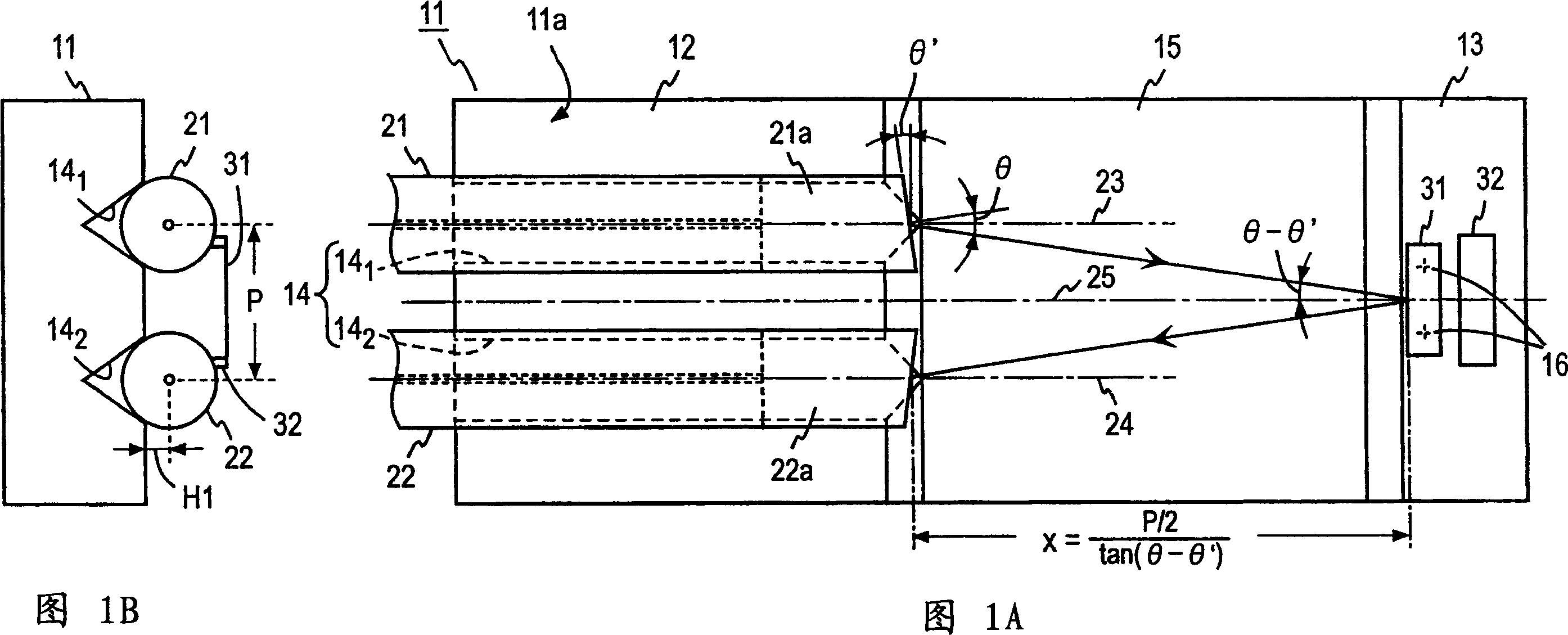

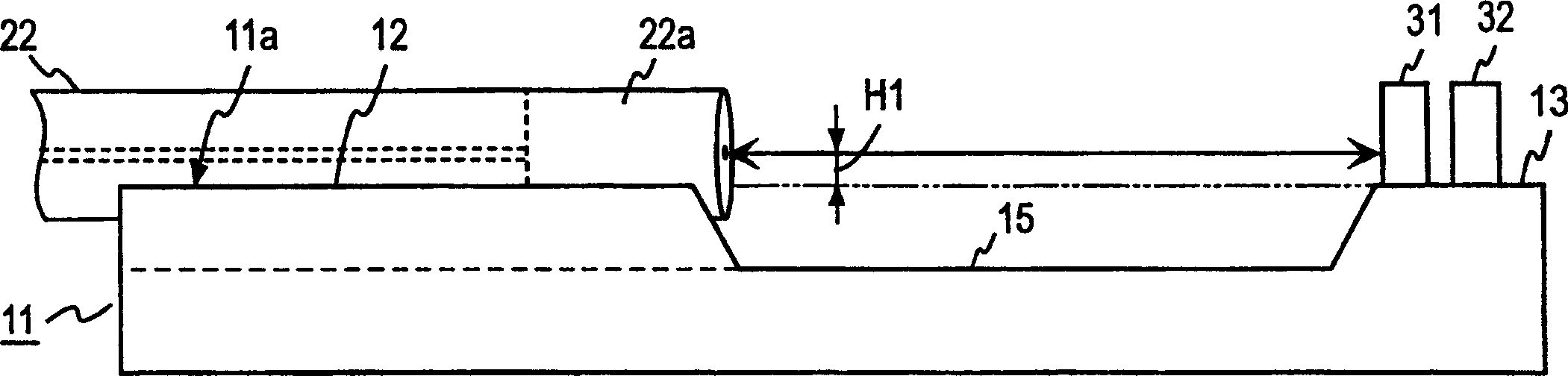

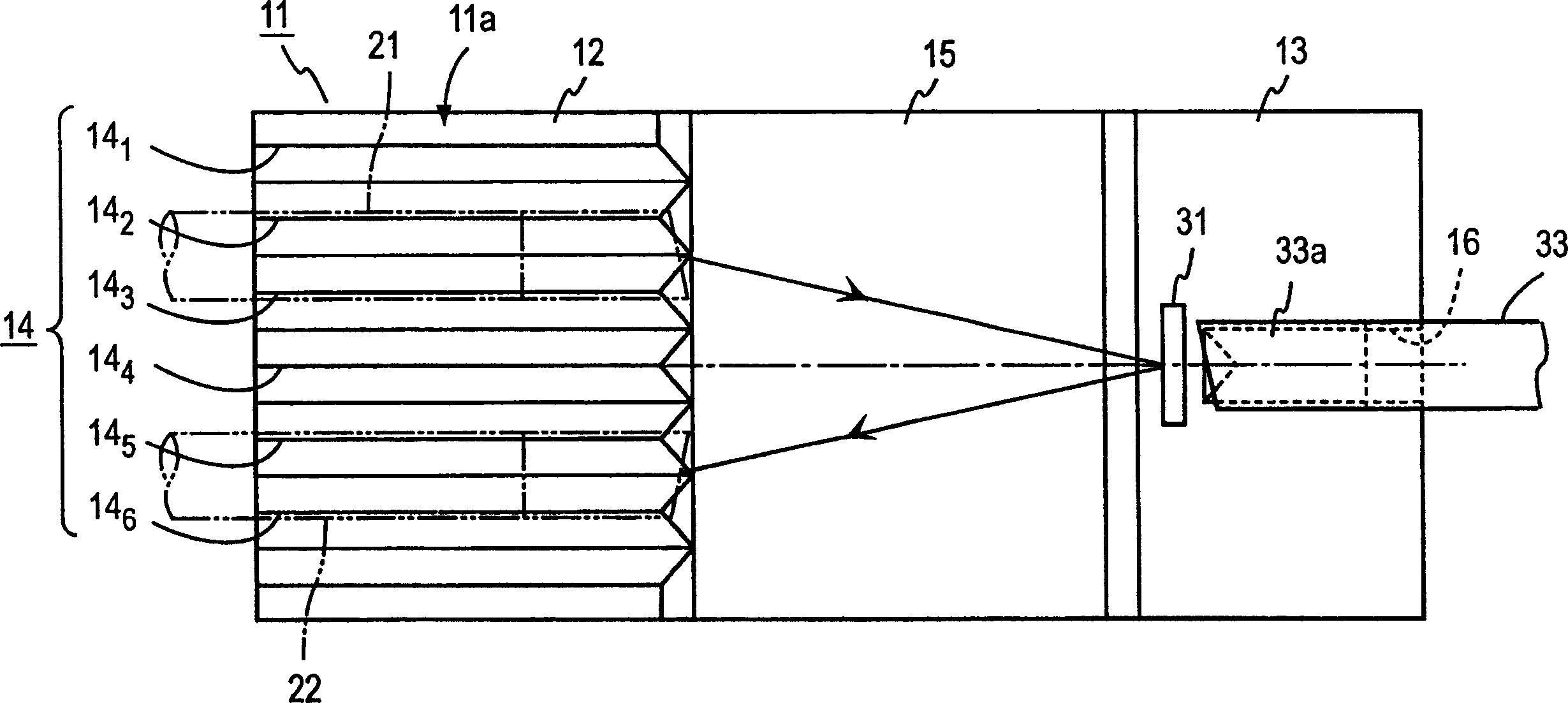

[0013] Referring first to FIG. 1, an embodiment of the present invention will be described. An optical fiber mounting portion 12 and a component mounting portion 13 are formed on a surface 11a of the base 11, the optical fiber mounting portion 12 has a positioning structure 14 for positioning a plurality of optical fibers, and is used to position a plurality of optical fibers so that they are in a parallel relationship and extend in a direction in which the optical fiber mounting portion 12 and the component mounting portion 13 are arranged opposite to each other. The positioning structure 14 positions the optical fibers in a direction perpendicular to the surface 11 a of the substrate 11 and in a direction in which the optical fibers are arranged side by side. The optical fibers 21 and 22 whose ends are positioned by the positioning structure 14 are mounted on the fiber mounting portion 12 . A splitter or filter 31 is mounted on the component mounting portion 13 at an interm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com