Directly-down backlight module

A backlight component, a direct-type technology, applied in optics, diffusion elements, nonlinear optics, etc., can solve problems such as waste of light, and achieve the effect of simplifying the production method and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

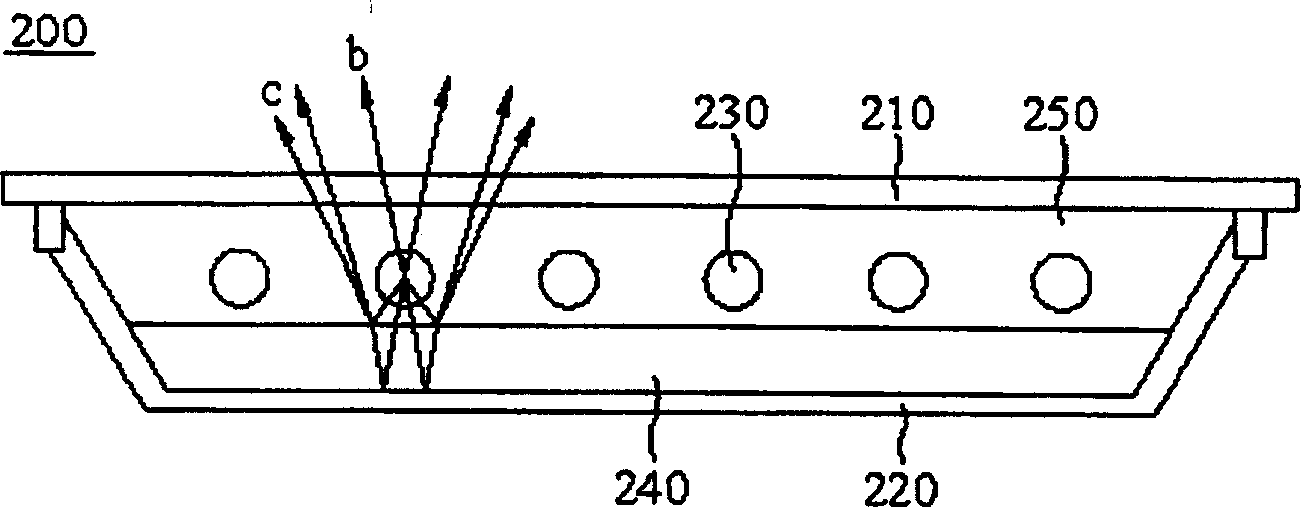

[0025] figure 2 It is a cross-sectional view of the direct-lit backlight assembly 200 according to the first embodiment of the present invention. A cavity 250 is formed by connecting a diffuser plate 210 and a reflector plate 220. A plurality of lamp tubes are arranged in the cavity 250 as light sources 230. Among them, one The light guide plate 240 is disposed between the light source 230 and the reflection plate 220 for changing the traveling route of the light.

[0026] After the light is emitted from the light source 230, the light b emitted from the upper part of the light source 230 directly passes through the diffusion plate 210 and exits the direct-lit backlight assembly 200; while the light c emitted from the lower part of the light source 230 first Entering the light guide plate 240, in the light guide plate 240, the optical path of the light c is changed, and then utilizes the reflection of the reflection plate 220, leaves the light guide plate 240, passes through ...

no. 2 example

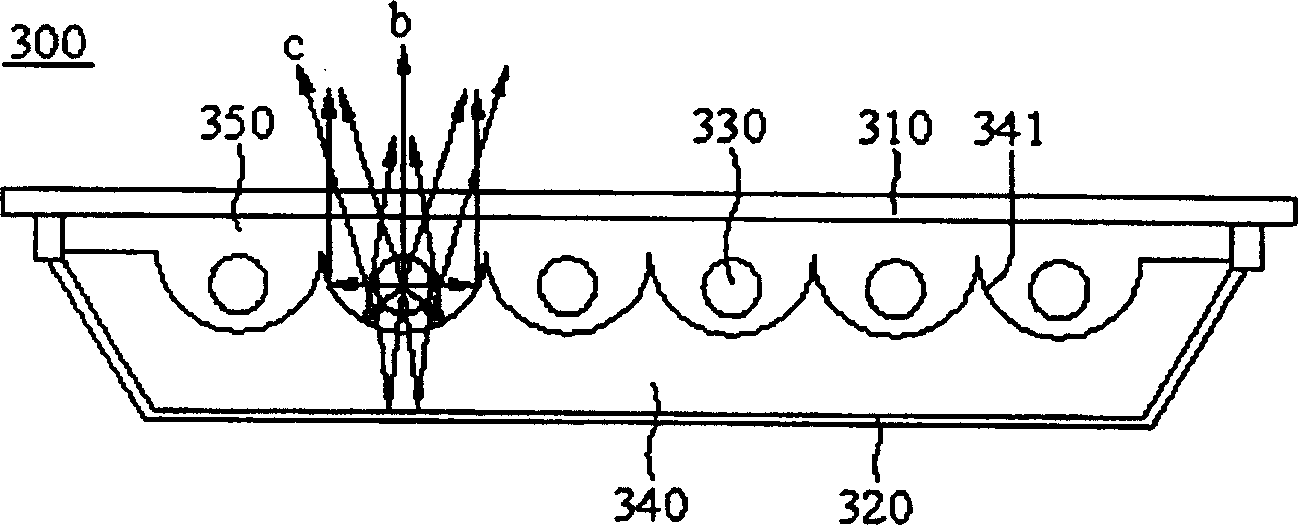

[0029] image 3 It is a cross-sectional view of a direct-lit backlight assembly 300 according to the second embodiment of the present invention. A cavity 350 is formed by connecting a diffuser plate 310 and a reflector plate 320. A plurality of lamp tubes are arranged in the cavity 350 as light sources 330. One of them The light guide plate 340 is arranged between the light source 330 and the reflector 320 to change the path of the light. The upper surface of the light guide plate 340 is designed as a mountain-shaped bulge between the light sources 330 according to the position of the light source 330. In an embodiment, the upper surface of the light guide plate 340 is in the form of a curved surface.

[0030] After the light is emitted from the light source 330, the light b emitted from the upper part of the light source 330 directly passes through the diffusion plate 310 and exits the direct-lit backlight assembly 300; while the light c emitted from the lower part of the lig...

no. 3 example

[0033] In this embodiment, in order to make the light more evenly distributed to achieve effective use, a diffuser 360 can be installed between the light guide plate 340 and the reflector 320 in the second embodiment as a light diffusion device, so that the light distribution is more efficient. uniform, such as Figure 4 As shown, light c is incident on the light guide plate 340 and then incident on the diffusion sheet 360. Due to the diffusion of the diffusion sheet 360, the light c is deviated. The direct type backlight assembly 300 is emitted through the diffusion plate 310 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com