A universalized, integrated and modularized IGBT traction converter module

A traction converter, a modular technology, is applied in the traction of DC motors, conversion devices for converting AC power input to DC power output, and output power, etc. The problem is not high, to achieve the effect of convenient installation and maintenance, optional cooling method, and high degree of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

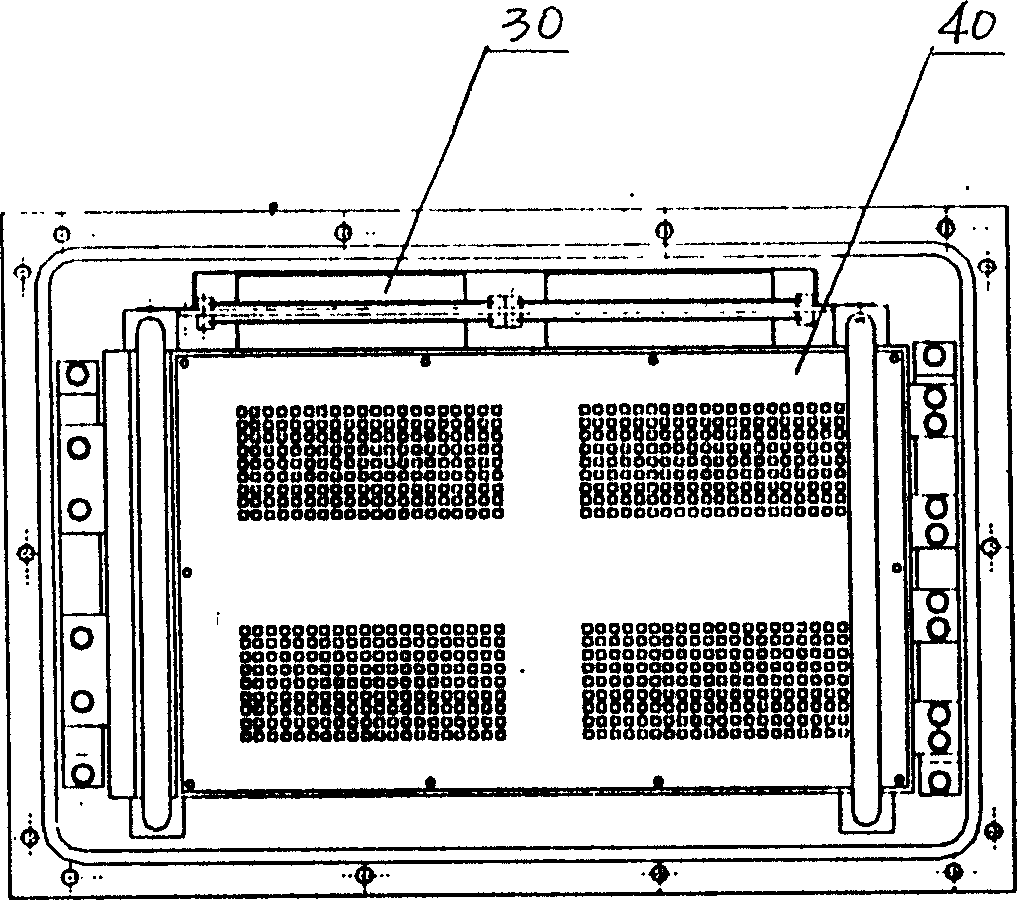

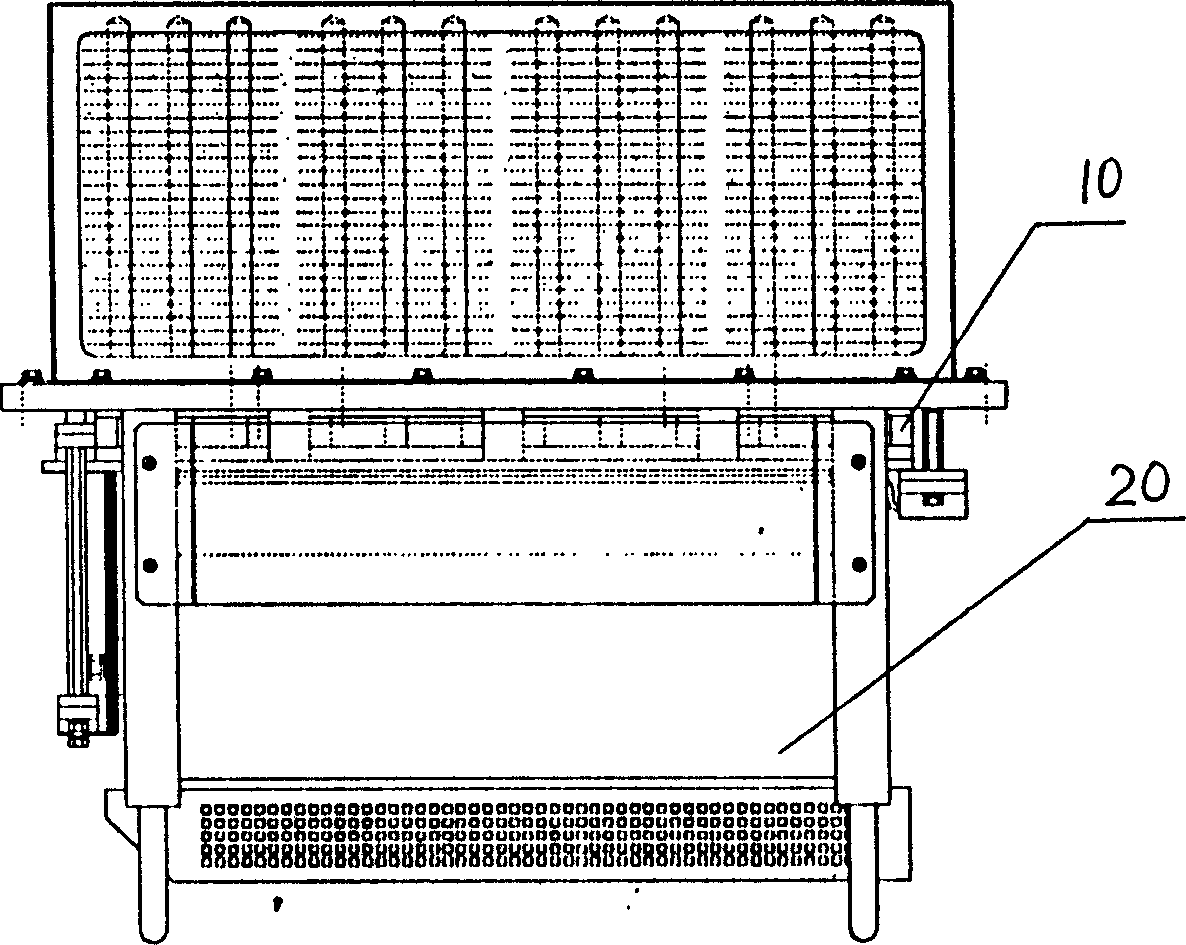

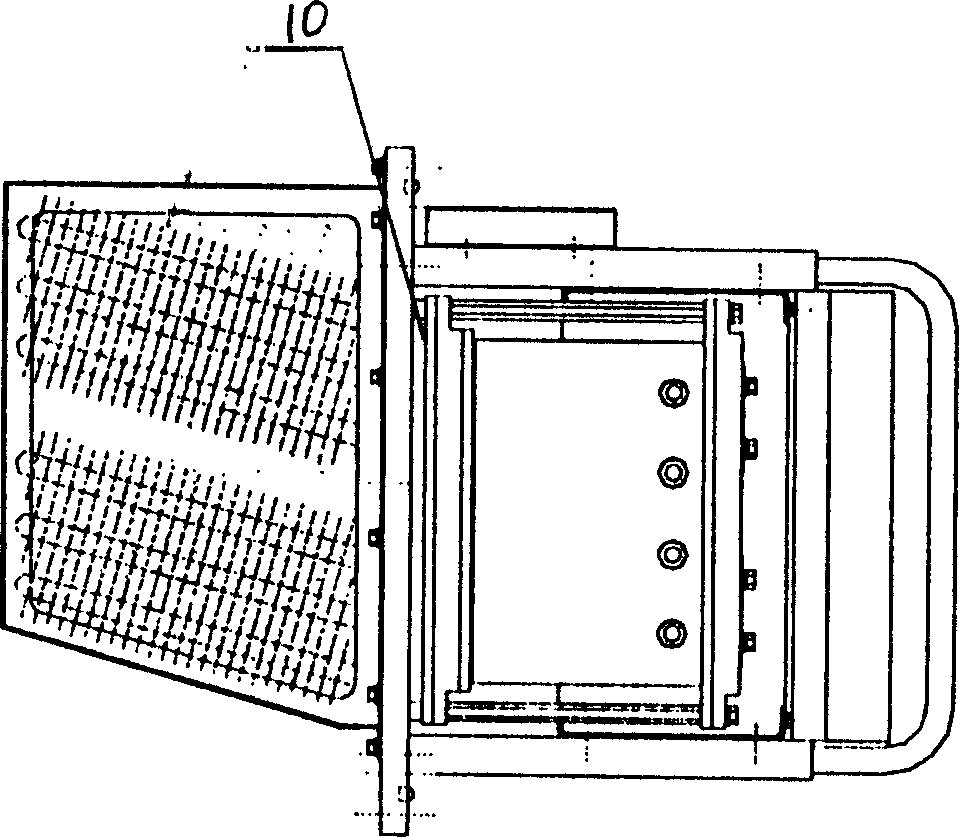

[0020] Such as Figure 1-4 As shown, it includes a converter unit 10, a DC support capacitor unit 20, a gate drive circuit 30 and a control box 40 installed in a drawer structure, wherein:

[0021] The converter unit 10 is installed on one side of the drawer structure, which includes IGBT components, radiators and low-inductance busbars; the IGBT components are arranged on the radiator according to the shape of the radiator and the uniform distribution of heat on the cooling surface, The low-sensitivity busbar is installed on the main terminal of the IGBT component through the combination screw, and the radiator is exposed outside the installation cabinet;

[0022] The DC support capacitor unit 20 is a low-inductance capacitor, and two identical capacitors are connected in parallel inside, and its four poles are respectively drawn out by four screws; The flow unit 10 is connected and installed on the support frame in the middle of the drawer structure through the mounting hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com