Mould clamping device

A mold clamping device and a combination device technology, applied in tents/canopies, building types, buildings, etc., can solve problems such as rising device costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

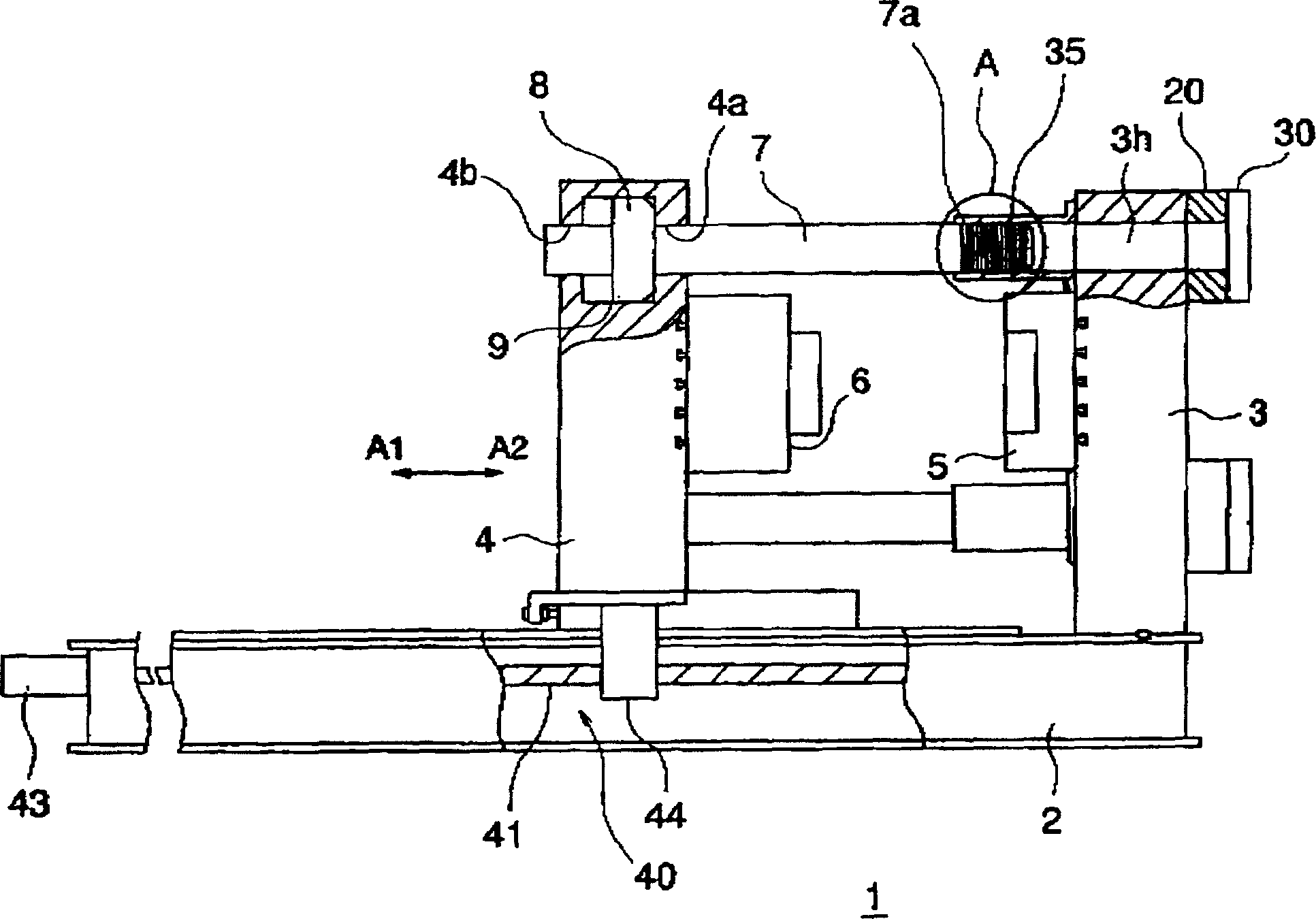

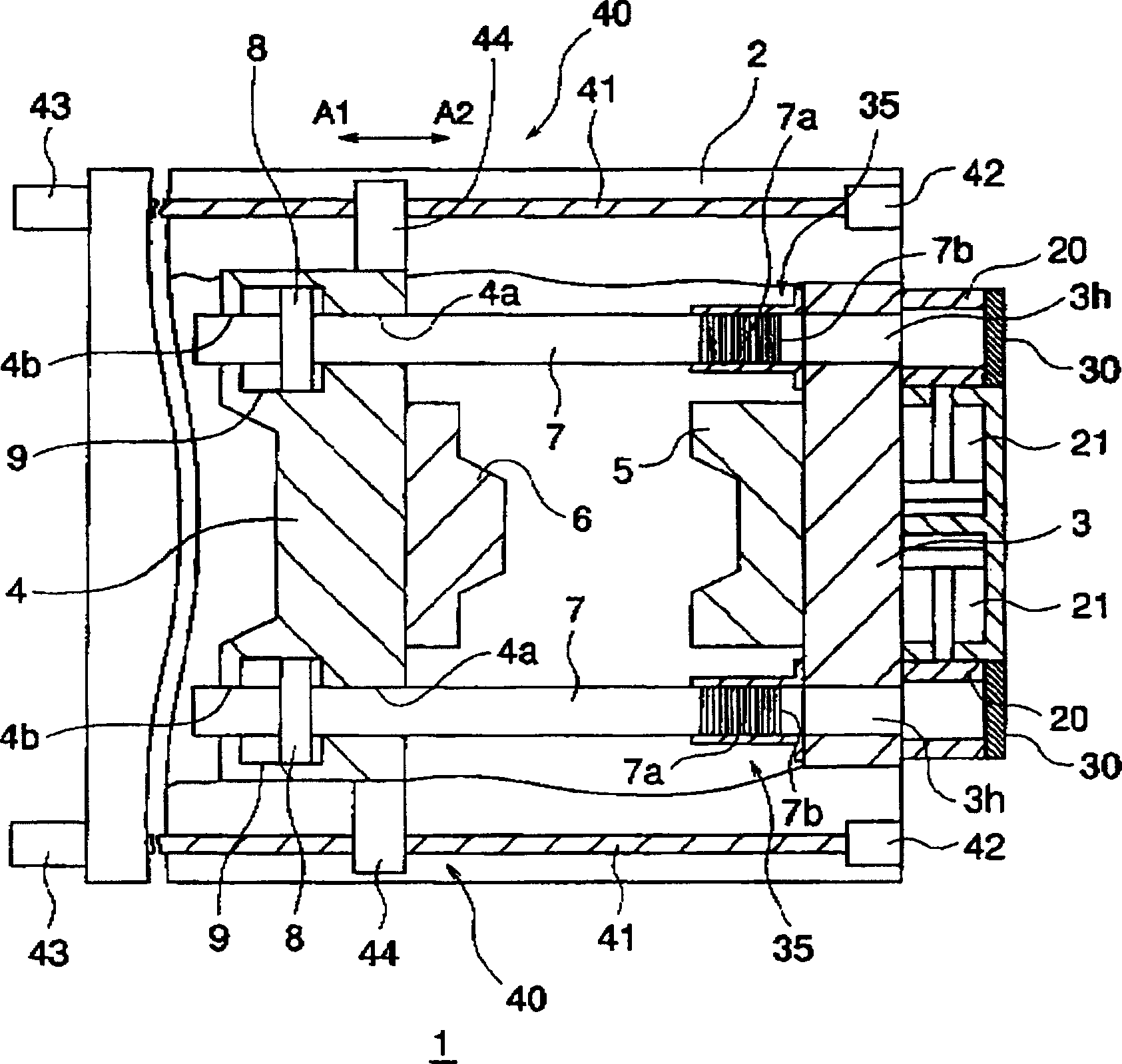

[0022] figure 1 is a diagram showing the structure of the mold clamping device according to the first embodiment of the present invention, figure 2 yes means figure 1 Horizontal cross-sectional view of the mold clamping device structure.

[0023] The mold clamping device 1 of this embodiment can be used, for example, in a die casting machine.

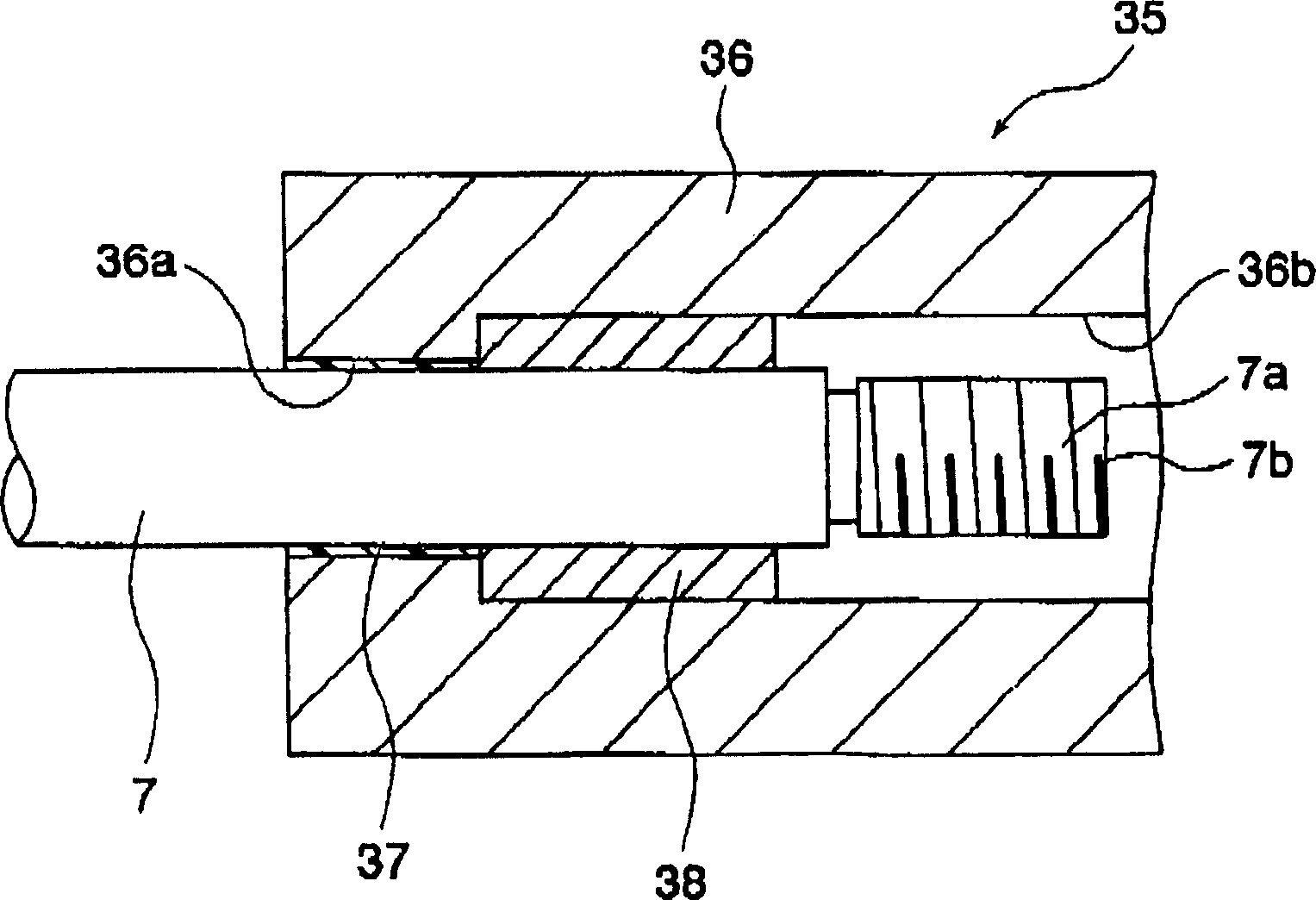

[0024] Such as figure 1 and figure 2 As shown, the mold clamping device 1 has: a base 2, a fixed plate 3 and a movable plate 4, a pair of pull rods (connecting rods) 7,7, a pair of mold clamping oil cylinders 9,9, a pair of moving mechanisms 40,40, a A pair of split nuts 20 , 20 , a pair of contact members 30 , 30 and a pair of guide portions 35 , 35 .

[0025] And the fixed plate 3 is the fixed plate of the present invention, the movable plate 4 is the movable plate of the present invention, the pull bar 7 is the pull bar of the present invention, the mold clamping oil cylinders 9 and 9 are the mold clamping oil cylinders of the...

no. 2 example

[0081] refer to Figure 10 ~ Figure 17 The second embodiment of the mold clamping device of the present invention will be described.

[0082] Figure 10 is a diagram showing the structure of the mold clamping device according to the second embodiment of the present invention, Figure 11 yes means Figure 10 Horizontal cross-sectional view of the mold clamping device structure.

[0083] The mold clamping device 1A of the second embodiment is used for a die casting machine as in the first embodiment.

[0084] Differences between the mold clamping device 1 of the first embodiment and the mold clamping device 1A of the second embodiment will be described.

[0085] exist figure 1 and figure 2 In the illustrated first embodiment of the mold clamping device 1 , the pistons 8 , 8 and the mold clamping cylinders 9 , 9 are provided on the movable platen 4 side. In contrast, in Figure 10 and Figure 12 In the mold clamping device 1A shown in the figure, pistons 8, 8 and cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com