Rotation stop device

A technology of anti-rotation and components, which is applied in the direction of electromechanical devices, transmission devices, transmission device parts, etc., can solve the problems of increasing the manufacturing cost of electric actuators, and achieve the effect of preventing rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

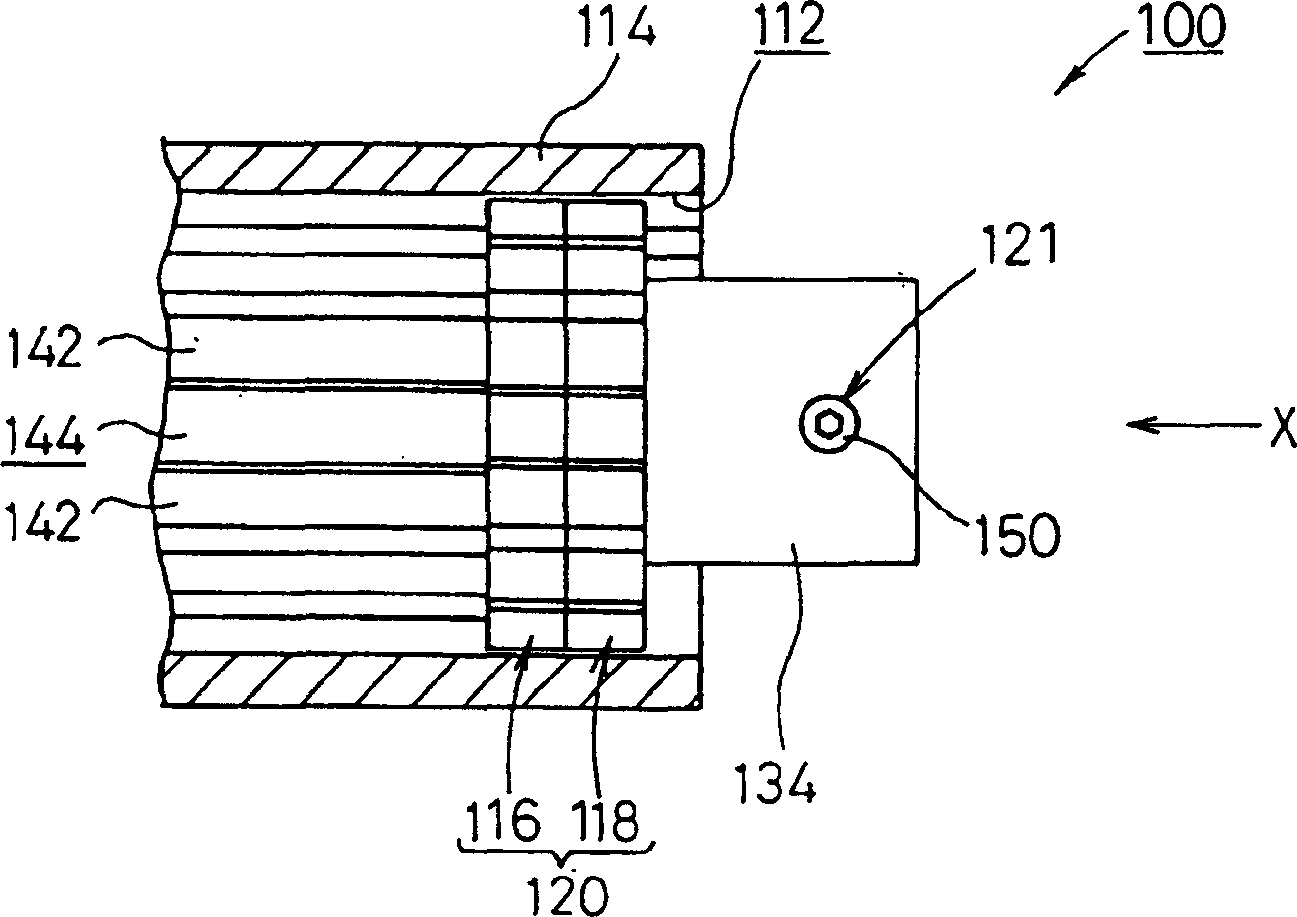

[0025] exist figure 1 Above, reference numeral 100 represents the anti-rotation device of the first embodiment of the present invention.

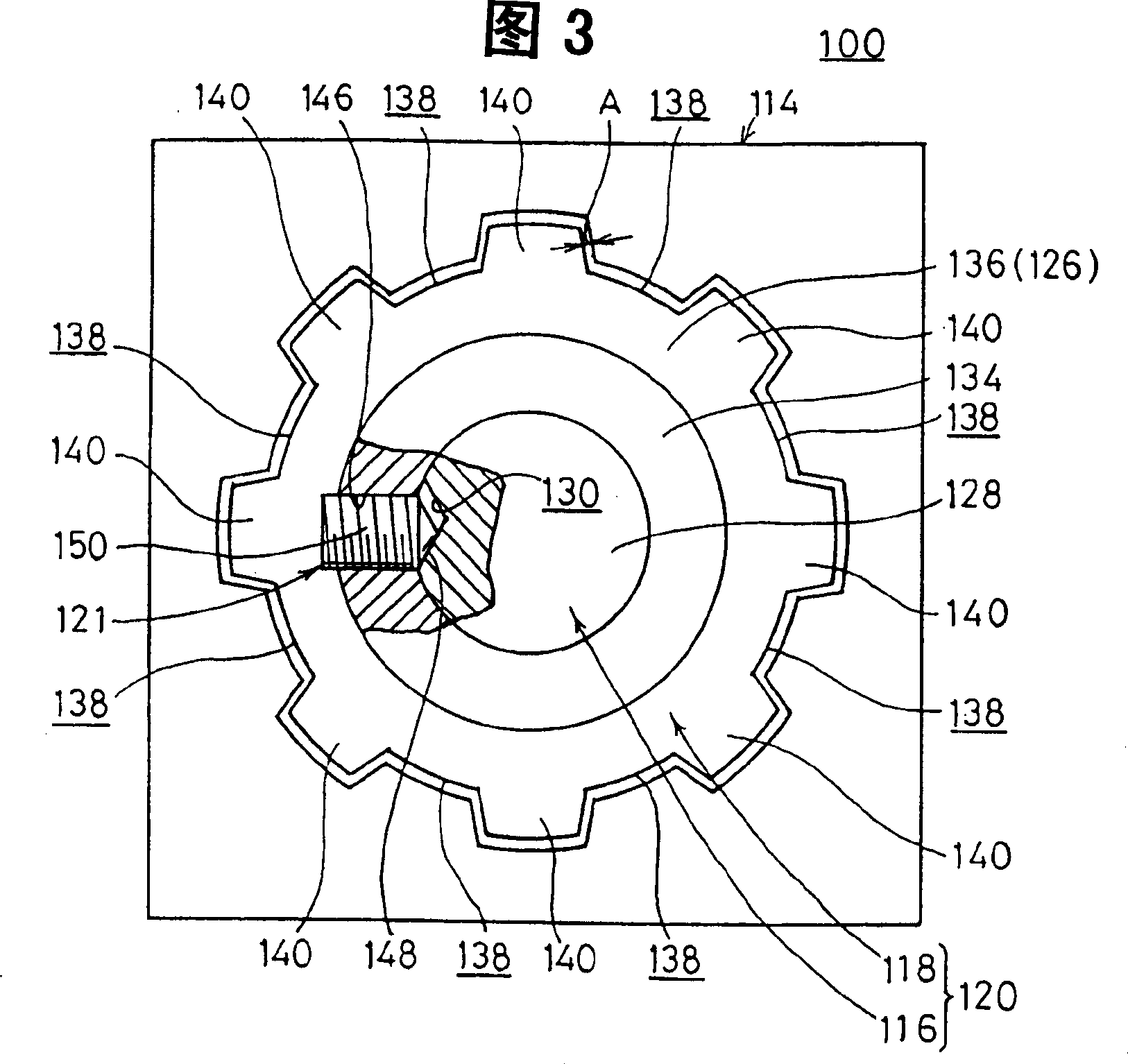

[0026] The anti-rotation device 100 is composed of a boss portion 114 , a spline shaft 120 , and a gap adjustment mechanism 121 . Wherein, the cross-section of the sleeve part 114 is roughly circular, and a through hole 112 is formed in the axial direction; the spline shaft 120 is respectively coaxially connected with the separated first spline shaft member 116 and the second spline shaft member 118. The shaft members 116, 118 are arranged to be freely slidable along the above-mentioned hole portion 112; the gap adjustment mechanism 121 is used to adjust the circumferential gap A formed between the inner wall surface of the above-mentioned sleeve portion 114 and the outer wall surface of the spline shaft portion 120 (refer to FIG. 3).

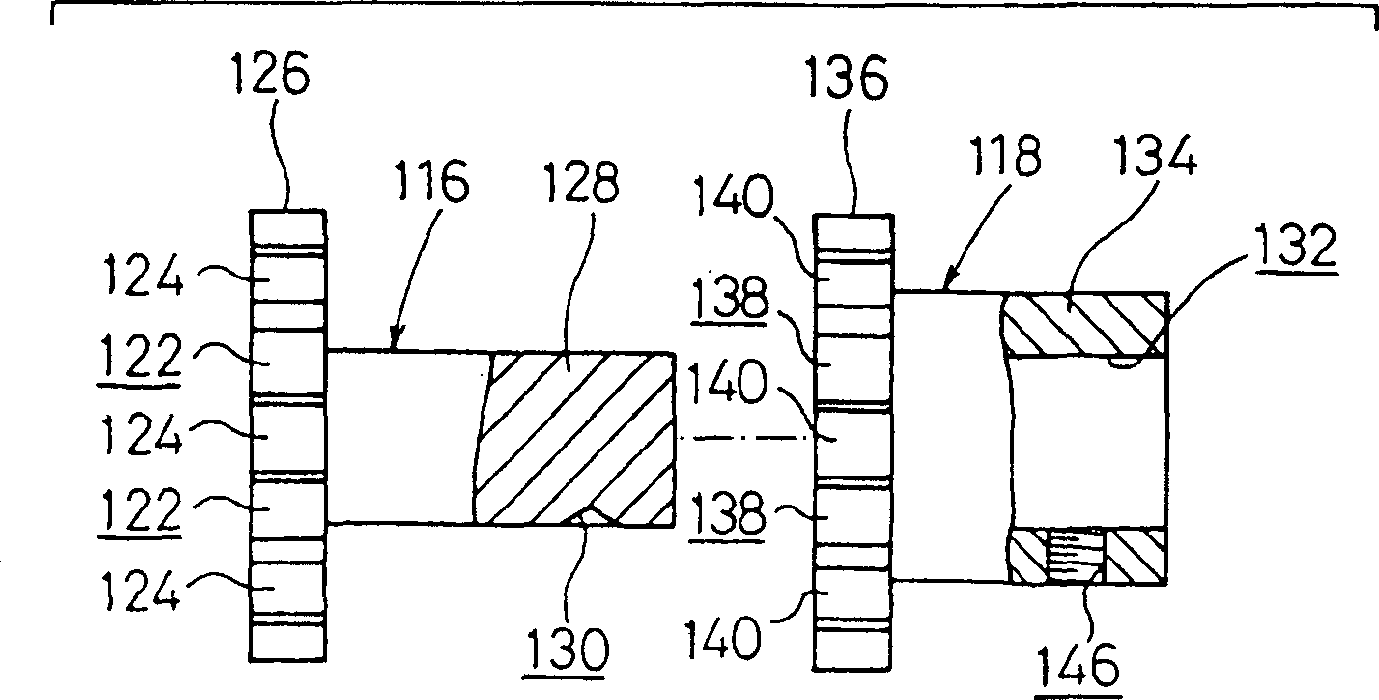

[0027] Such as figure 2 As shown, the first splined shaft member 116 has a disc portion 126 and a sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com