Hydrofining catalyst containing molybdenum and/or tungsten and nickel and/or cobalt and its preparation process

A hydrorefining and catalyst technology, applied in refining to remove heteroatoms, etc., can solve the problem of low hydrodesulfurization activity and achieve the effect of high hydrodesulfurization activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

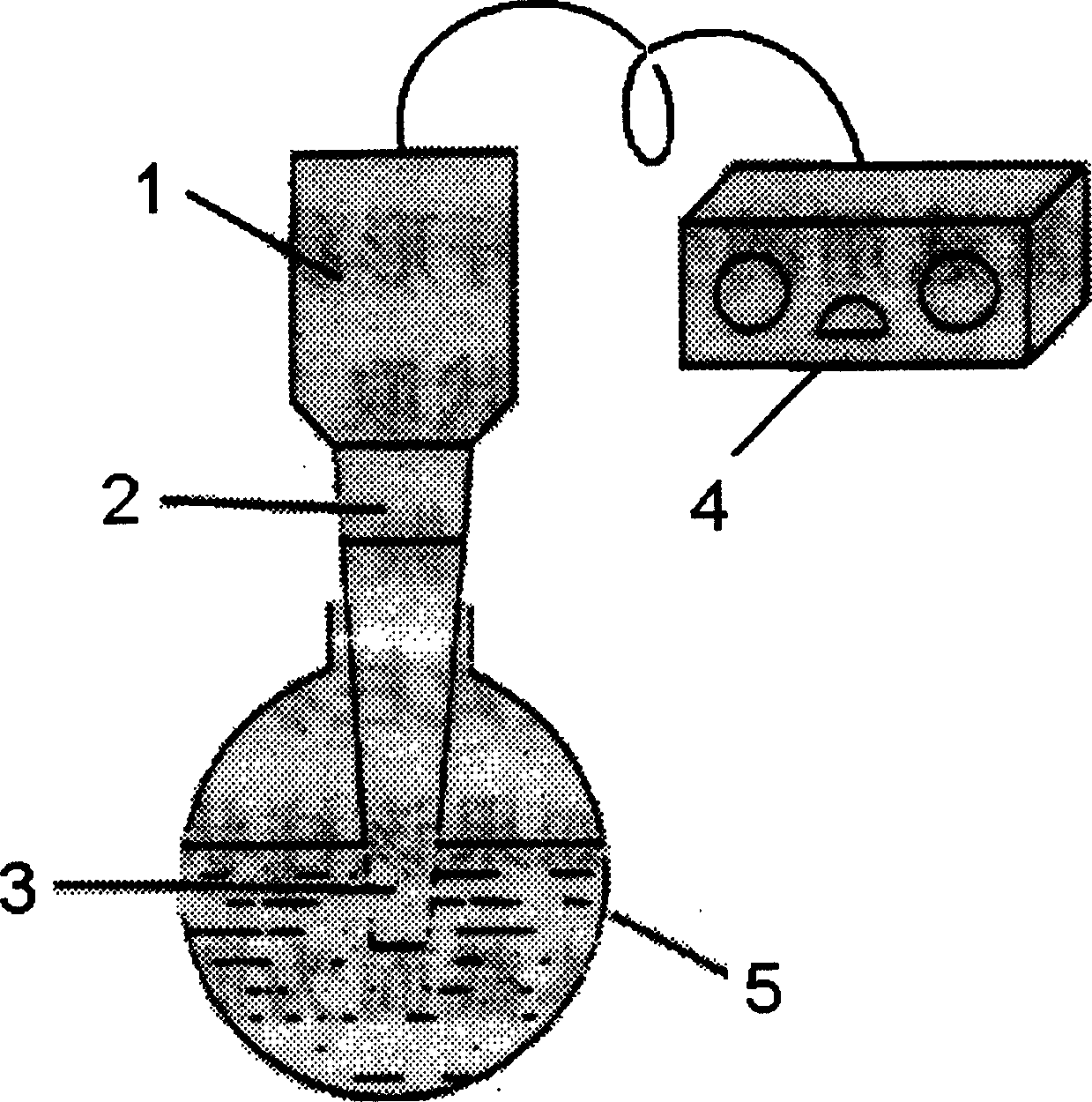

[0029] 50 grams of industrial gamma-alumina carrier (Changling Refinery Catalyst Factory product) is placed in reaction vessel 5 (see figure 1 ), weigh ammonium metatungstate ((NH 4 ) 2 W 4 o 13 18H 2 O, Sichuan, chemically pure) 50 grams and nickel nitrate (Ni(NO 3 ) 2 ·6H 2 (2, Yixing, chemically pure) 23 grams of water is dissolved into 200 milliliters of solutions, and solution is added to reaction vessel 5 (the liquid-solid ratio of solution and gamma-alumina is 4 milliliters / gram) and soaks for 3 hours, after soaking for 30 minutes, put The probe 3 is inserted into the impregnation solution impregnated with the alumina carrier, the generator 4 is turned on, and ultrasonic radiation is used for 30 minutes. The volume ratio of the ultrasonic radiation power to the impregnation solution is 1.5 W / ml, cooled, filtered, and put into a microwave oven (brand Galanz WD900B) for 15 minutes. Catalyst B-1 was obtained. The catalyst B-1 was dried at 120° C. for 4 hours, and t...

example 2

[0039] 50 grams of industrial gamma-alumina carrier (Changling Refinery Catalyst Factory product) is placed in reaction vessel 5 (see figure 1 ), weigh ammonium metatungstate (NH 4 ) 2 W 4 o 13 18H 2 O, Sichuan, chemically pure) 26 grams and nickel nitrate (Ni(NO 3 ) 2 ·6H 2 (2, Yixing, chemically pure) 9 grams of water are dissolved into 100 milliliters of solutions, and the solution is added to reaction vessel 5 (the liquid-solid ratio of solution and γ-alumina is 2 milliliters / gram) and soaked for 2 hours, after soaking for 30 minutes, The probe 3 is inserted into the impregnation solution impregnated with the alumina carrier, the generator 4 is turned on, and ultrasonic radiation is used for 60 minutes. The volume ratio of the ultrasonic radiation power to the impregnation solution is 3 watts / ml, cooled, filtered, and put into a microwave oven (brand Galanz WD900B) for 20 minutes. Catalyst B-2 was obtained. The catalyst B-2 was dried at 120° C. for 4 hours, and the...

example 3

[0041] 50 grams of industrial gamma-alumina carrier (Changling Refinery Catalyst Factory product) is placed in reaction vessel 5 (see figure 1 ), weigh ammonium metatungstate (NH 4 ) 2 W 4 o 13 18H 2 O, Sichuan, chemically pure) 35 grams and nickel nitrate (Ni(NO 3 ) 2 ·6H 2 (2, Yixing, chemically pure) 18 grams of water is dissolved into 300 milliliters of solutions, and solution is added to reaction vessel 5 (the liquid-solid ratio of solution and γ-alumina is 6 milliliters / gram) and soaks for 4 hours, after soaking for 30 minutes, put The probe 3 is inserted into the impregnation solution impregnated with the alumina carrier, the generator 4 is turned on, and ultrasonic radiation is used for 100 minutes. The volume ratio of the ultrasonic radiation power to the impregnation solution is 1 W / ml, cooled, filtered, and put into a microwave oven (brand Galanz WD900B) for 20 minutes. Catalyst B-3 was obtained. The catalyst B-3 was dried at 120° C. for 4 hours, and the wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com