Hydrotreating catalyst and application thereof

A hydrotreating and catalyst technology, applied in physical/chemical process catalysts, molecular sieve catalysts, organic compound/hydride/coordination complex catalysts, etc., which can solve the problems of reduced reaction rate and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

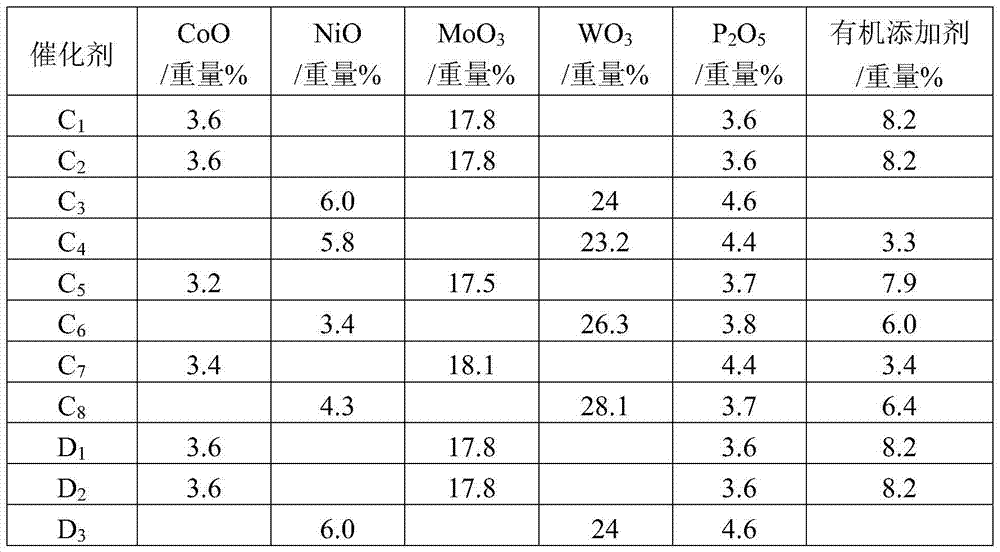

Examples

Embodiment 1

[0069] Weigh 493.0 grams of Changling dry rubber powder, 26.1 grams of HY molecular sieves, 30.8 grams of methylcellulose and 525 milliliters of aqueous solution containing 1.0% by weight of nitric acid and mix evenly, extrude into a clover-shaped bar with a circumscribed circle diameter of 1.6 mm, and heat at 120 ° C Let dry for 4 hours. Weigh 300 grams of dried strips, place them in a tube furnace to isolate the air, raise the temperature to 580° C. at 4° C. / min, and carbonize for 4 hours. Then, feed 150 standard liters / (kg·hour) of water vapor, raise the temperature to 820°C at 6°C / min, and activate for 60 minutes to obtain the carbon-containing alumina carrier S l . Among them, 3.0% by weight of carbon and 5.0% by weight of molecular sieves are contained.

[0070] Weigh the above S l 100.0 grams of the carrier was impregnated with 94 milliliters of an aqueous solution containing 9.7 grams of basic cobalt carbonate, 27.8 grams of molybdenum trioxide, 7.7 grams of phospho...

Embodiment 2

[0072] Take by weighing 493.0 grams of Changling dry rubber powder, 26.1 grams of HY type molecular sieves, 12.3 grams of methylcellulose and 525 milliliters of aqueous solutions containing 26.4 grams of oxalic acid and 1.0% by weight of nitric acid, mix evenly, and extrude into a clover shape with a circumscribed circle diameter of 1.6 mm Strips, dried at 120°C for 4 hours. Wherein, the weight ratio of oxalic acid to methylcellulose is 2.14. Weigh 300 grams of dried strips, place them in a tube furnace to isolate the air, raise the temperature to 580° C. at 4° C. / min, and carbonize for 4 hours. Then, feed 150 standard liters / (kg·hour) of water vapor, raise the temperature to 820°C at 6°C / min, and activate for 60 minutes to obtain the carbon-containing alumina carrier S 2 . Among them, 3.0% by weight of carbon and 5.0% by weight of molecular sieves are contained.

[0073] Weigh the above S 2 100.0 grams of the carrier was impregnated with 94 milliliters of an aqueous solut...

Embodiment 3

[0075] Take by weighing 493.0 grams of Changling dry rubber powder, 23.9 grams of Hβ molecular sieves, 12.3 grams of methylcellulose and 525 milliliters of aqueous solutions containing 26.4 grams of oxalic acid and 1.0% by weight of nitric acid, mix evenly, and extrude into a clover-shaped bar with a circumscribed circle diameter of 1.6 mm , dried at 120°C for 4 hours. Wherein, the weight ratio of oxalic acid to methylcellulose is 2.14. Weigh 300 grams of dried strips, place them in a tube furnace to isolate the air, raise the temperature to 580° C. at 4° C. / min, and carbonize for 4 hours. Then, feed 150 standard liters / (kg·hour) of water vapor, raise the temperature to 820°C at 6°C / min, and activate for 60 minutes to obtain the carbon-containing alumina carrier S 3 . Among them, 3.0% by weight of carbon and 5.0% by weight of molecular sieves are contained.

[0076] Weigh the above S 3 100 grams of carrier was impregnated with 95 milliliters of an aqueous solution containi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com