Engine built-in reversing mechanism

A technology of engine and reverse gear, applied in the direction of machines/engines, mechanical equipment, etc., can solve the problems of lack of second-gear transmission ratio, small transmission ratio, poor strength, etc., to achieve guaranteed strength, reasonable transmission ratio of each gear, and good strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

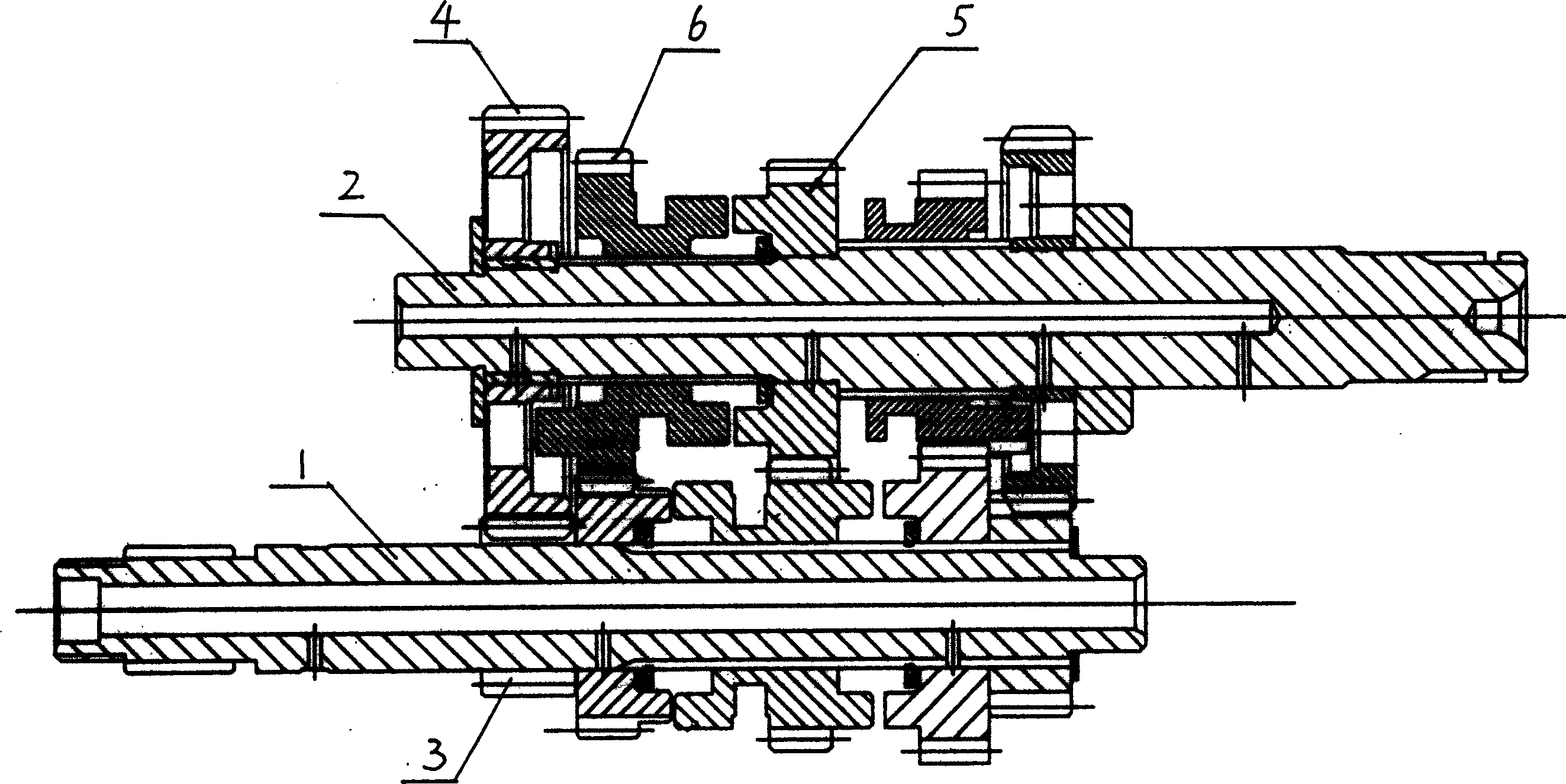

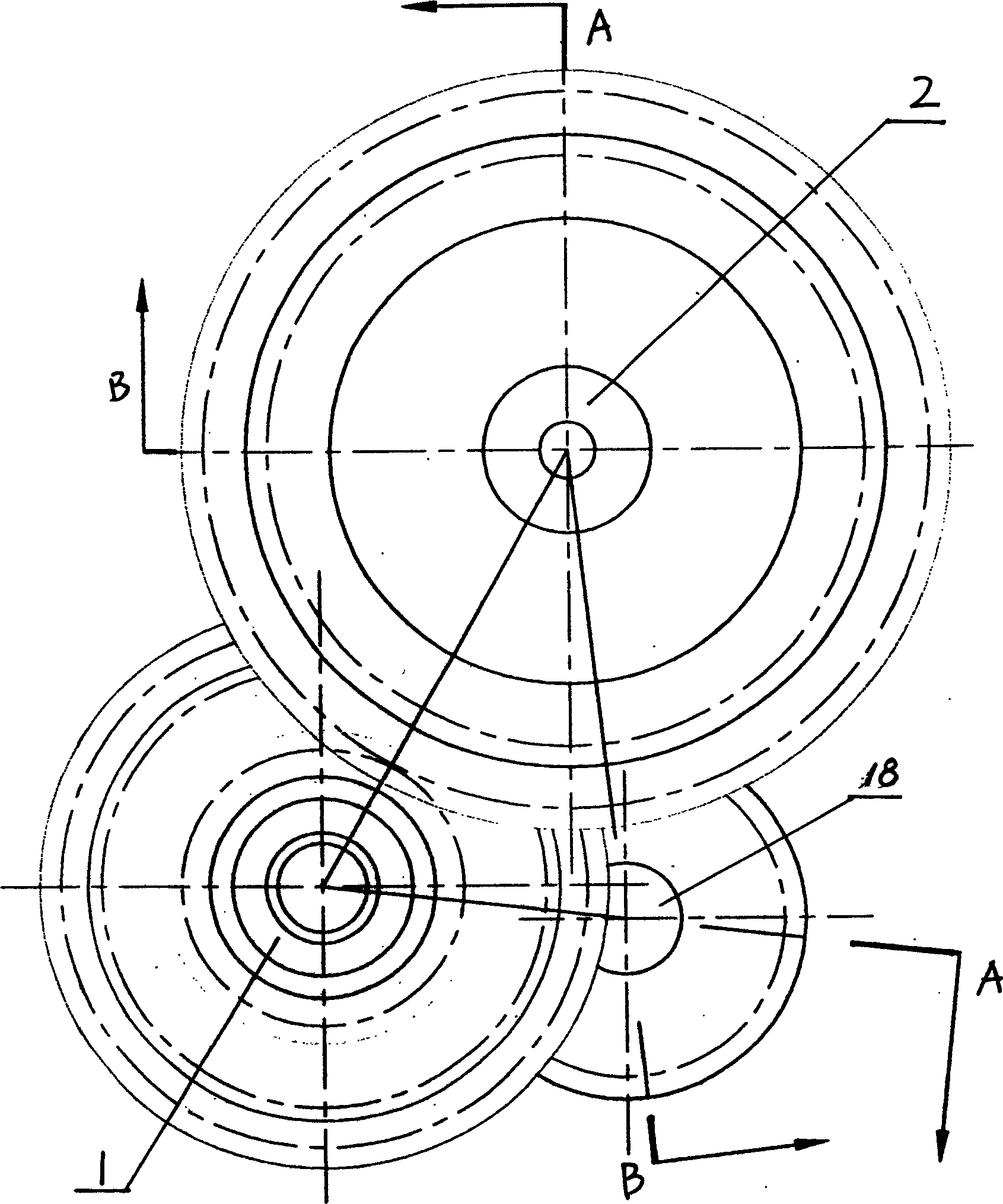

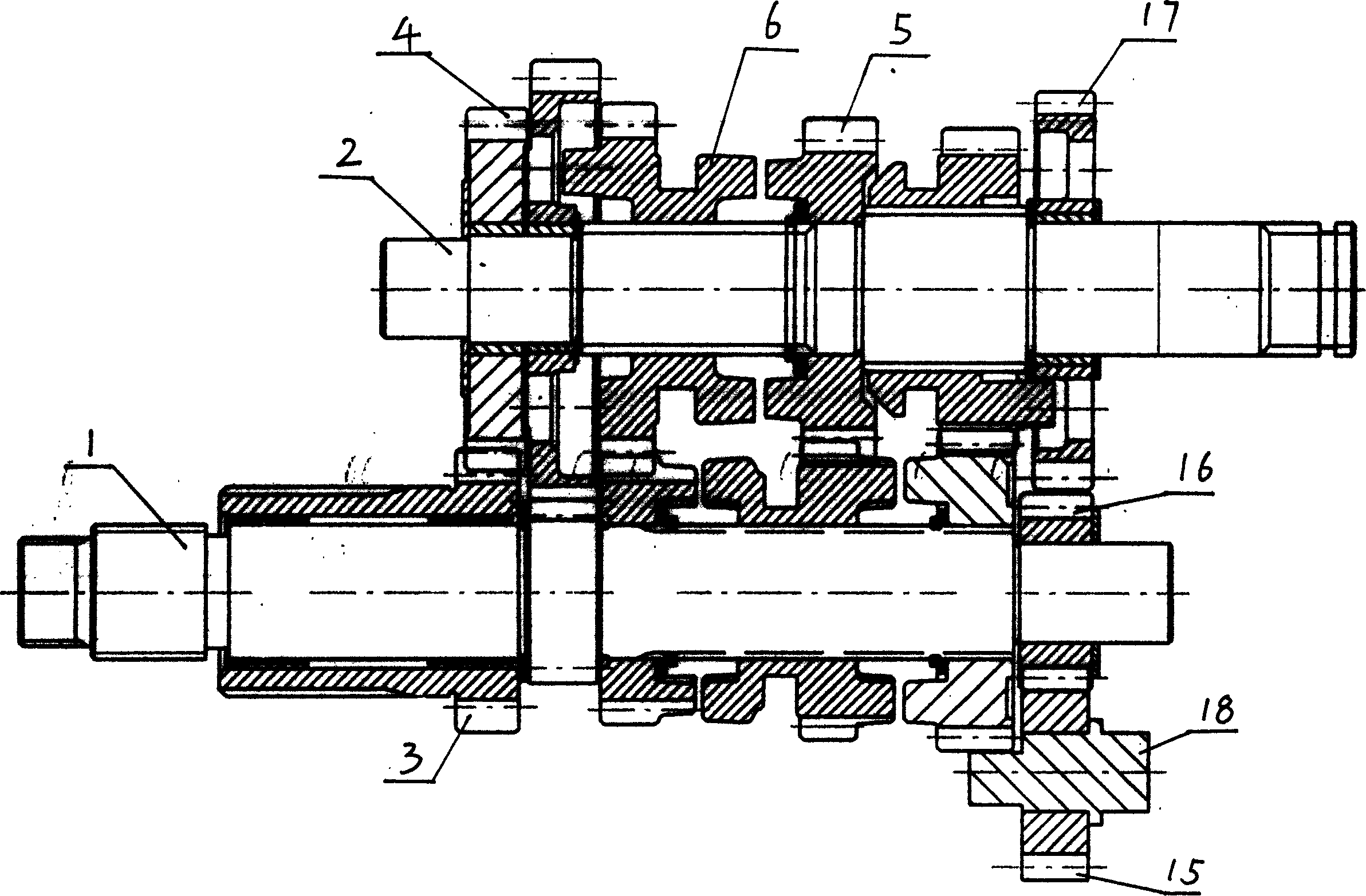

[0014] As shown in Figure 5, Figure 6 and Figure 7 Shown: the present invention is made up of main shaft 1, secondary shaft 2, first gear driving gear 3, first gear driven gear 4, gear 5, spline gear 6, gear shift slider 7, first-stage double gear 8, bridge gear 9. It consists of a first-stage double gear shaft 10, a bridge gear shaft 11, a washer 12, a first-stage double gear bushing 13 and a bridge gear bushing 14. There is a driving gear 3 on the main shaft 1 and a driving gear 3 on the secondary shaft 2. There is a driven gear 4 and a gear 5, and a spline gear 6 is installed between the gear 5 and the driven gear 4. Its structural features are: A. A shifting gear is arranged at the position corresponding to the gear 5 on the main shaft 1 Slider 7, the shift slider 7 is set on the main shaft 1 through splines and spline grooves; B, one side of the secondary shaft 2 is provided with a first-stage double gear 8 and a bridge gear 9, and the first-stage double gear 8 One ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com