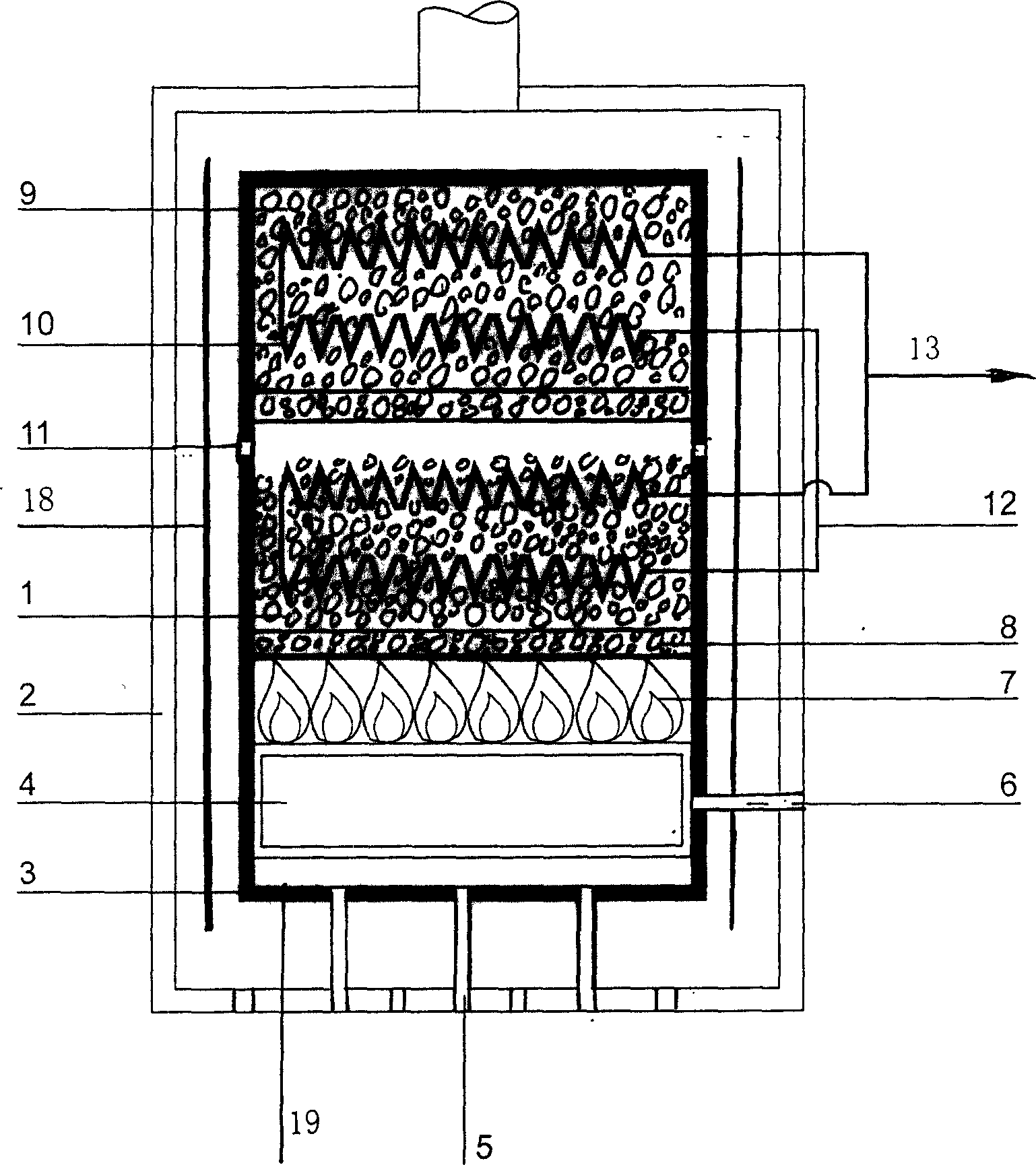

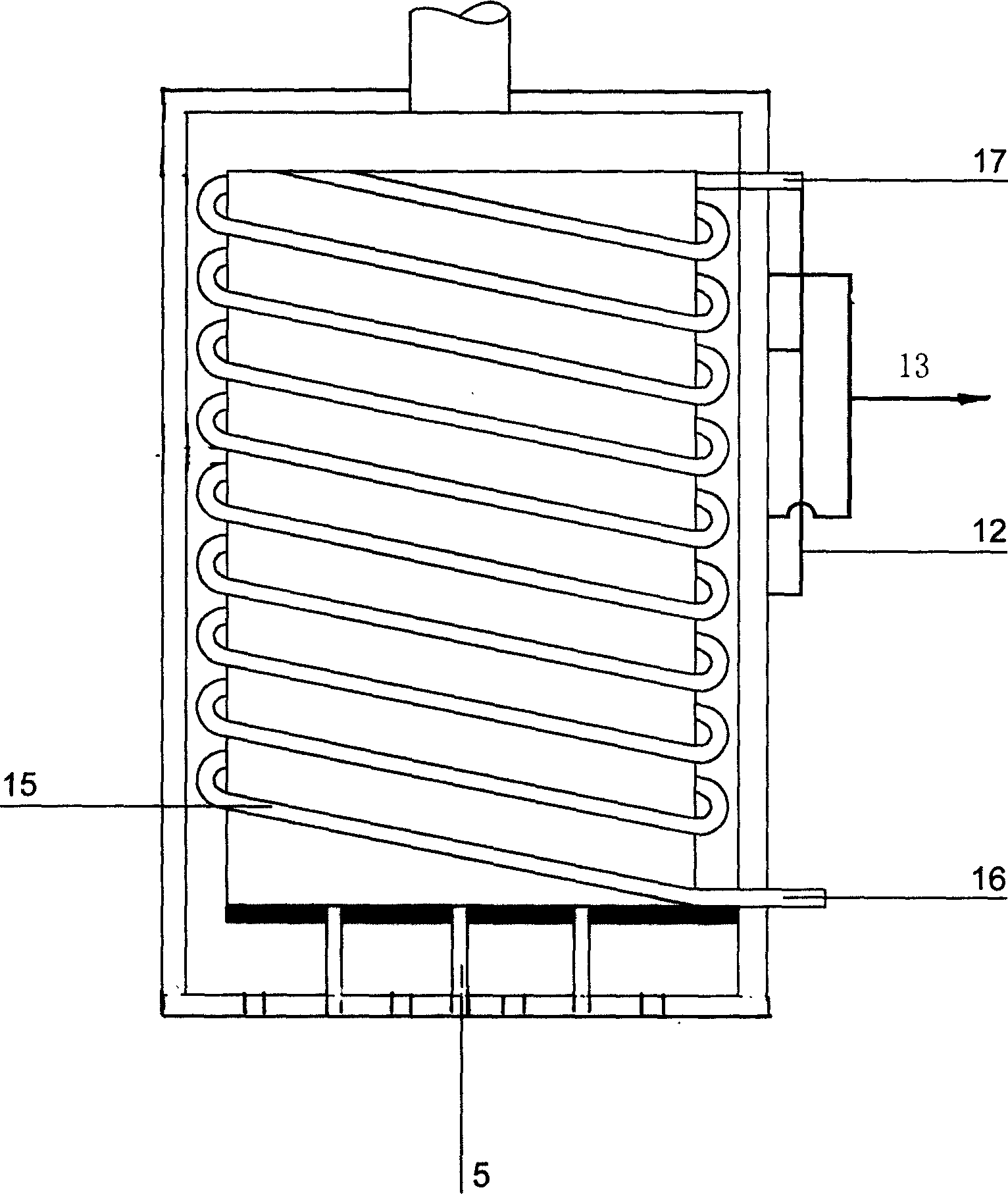

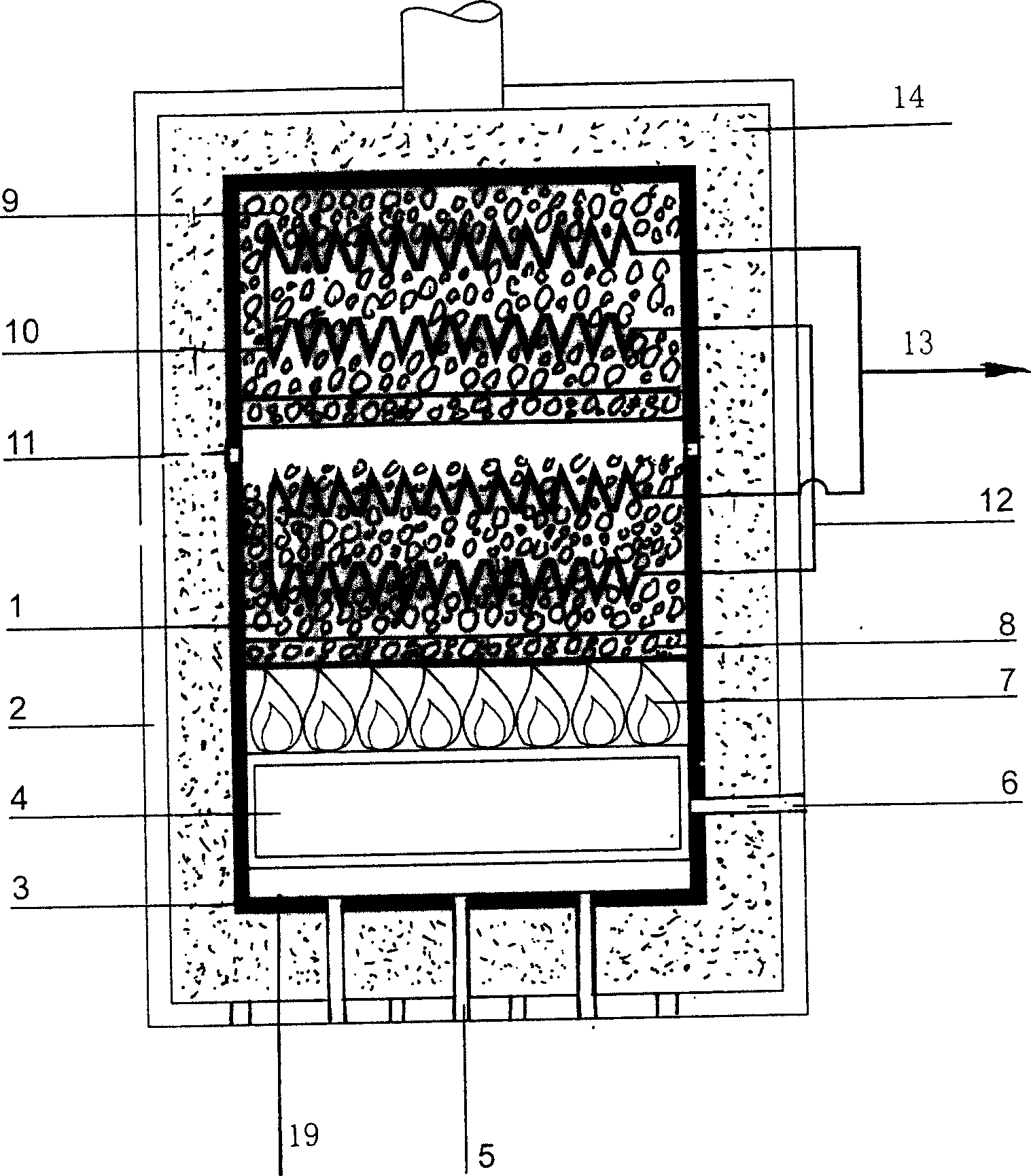

Porous ceramic combustion gas water heater

A technology of gas water heaters and porous ceramics, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of increased content, achieve low NOX emissions, compact structure, and improve thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] A porous ceramic water heater for testing has been designed according to the technical scheme of the present invention, and its given and measured parameters are as follows:

[0020] Water flow: Q 水 =100kg / h, natural gas flow rate: Q 天然气 =0.43~0.54m 3 / h

[0021] Calorific value of natural gas: H 天然气 =33440(KJ / m 3 ), excess air coefficient: α=1.1~1.5

[0022] Exhaust gas temperature: t 烟 =150~200℃, water inlet temperature: t 进口 =25°C

[0023] Water outlet temperature: t 出口 =45~56℃, specific heat of water: C p水 =4.18KJ / kg·K

[0024] efficiency(%)

[0025] It can be seen that the porous ceramic water heater has high thermal efficiency and low NO X Emissions, which is very beneficial to the user, it saves the natural gas used and thus saves money. Almost every house has a water heater, and its annual NO X The emissions are considerable. If each water heater has its NO X Emissions are only 40-50ppm, the annual NO X At least 100 times lower, whic...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap