Continuous centrifuge

A technology of centrifuge and centrifugal turning blue, which is applied in the direction of centrifuge, centrifuge with rotating drum, separation of sugar crystals, etc., and can solve the problem of high power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

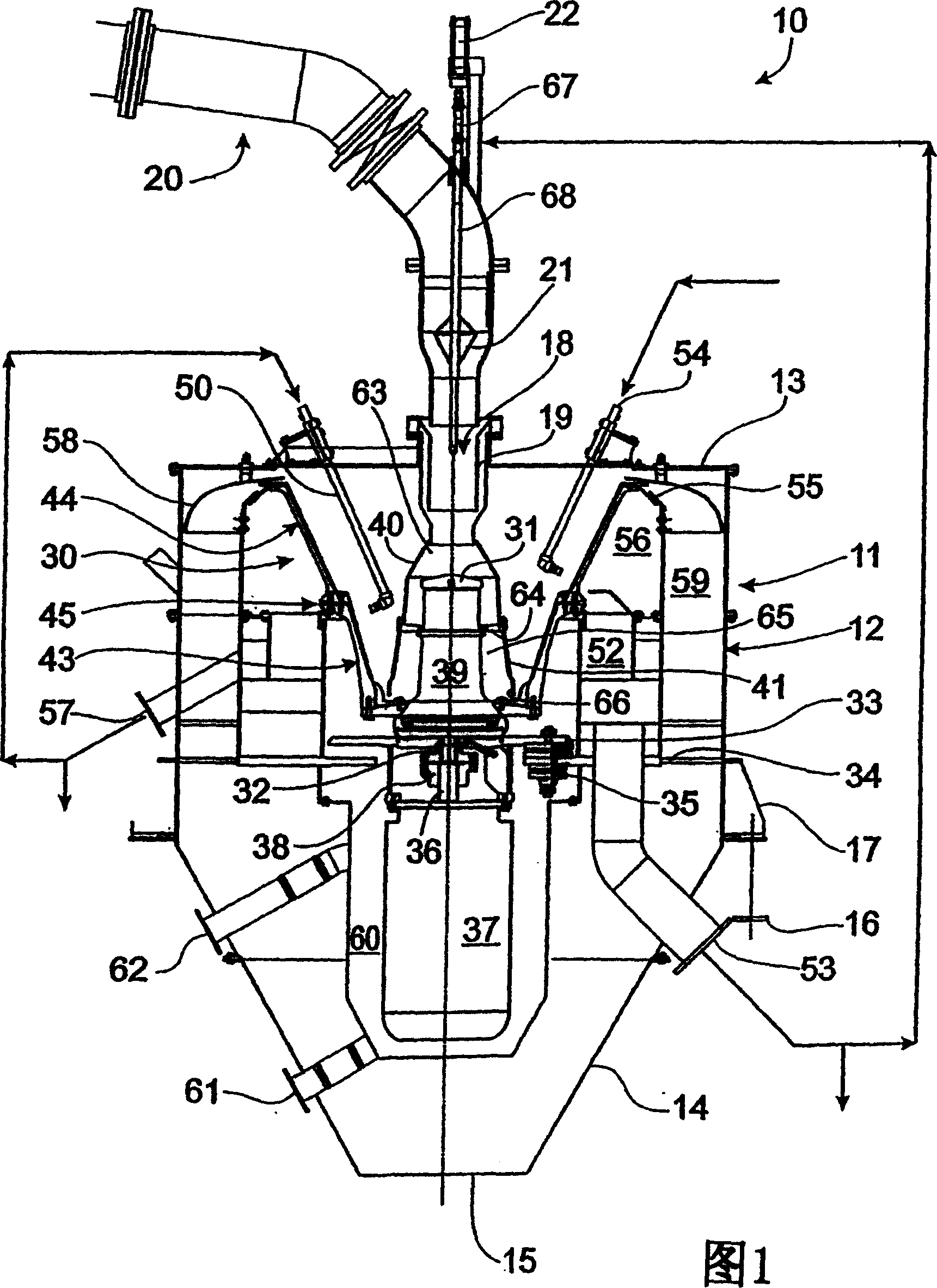

[0046] Referring to Fig. 1, the continuous centrifuge 10 has a housing 11, a detachable top wall 13 and a conical bottom wall 14, wherein the housing 11 has a substantially barrel-shaped side wall 12, the bottom wall 14 With a sugar crystal discharge port 15 . Housing 11 is mounted on a suitable structure 16 via brackets 17 .

[0047] The center of the top wall 13 has a juice inlet 18 which is heated by a steam jacket 19 to control the temperature and viscosity of the juice sent to the centrifuge 10 .

[0048] The juice feed pipe 20 has a flow control valve 21 which is controlled by a pneumatic spool 22 to control the flow of juice to the centrifuge 10 . A flow sensor (not shown) may be connected to the pneumatic spool 22 to measure the power demand of the drive motor to increase juice flow as the flow rate decreases.

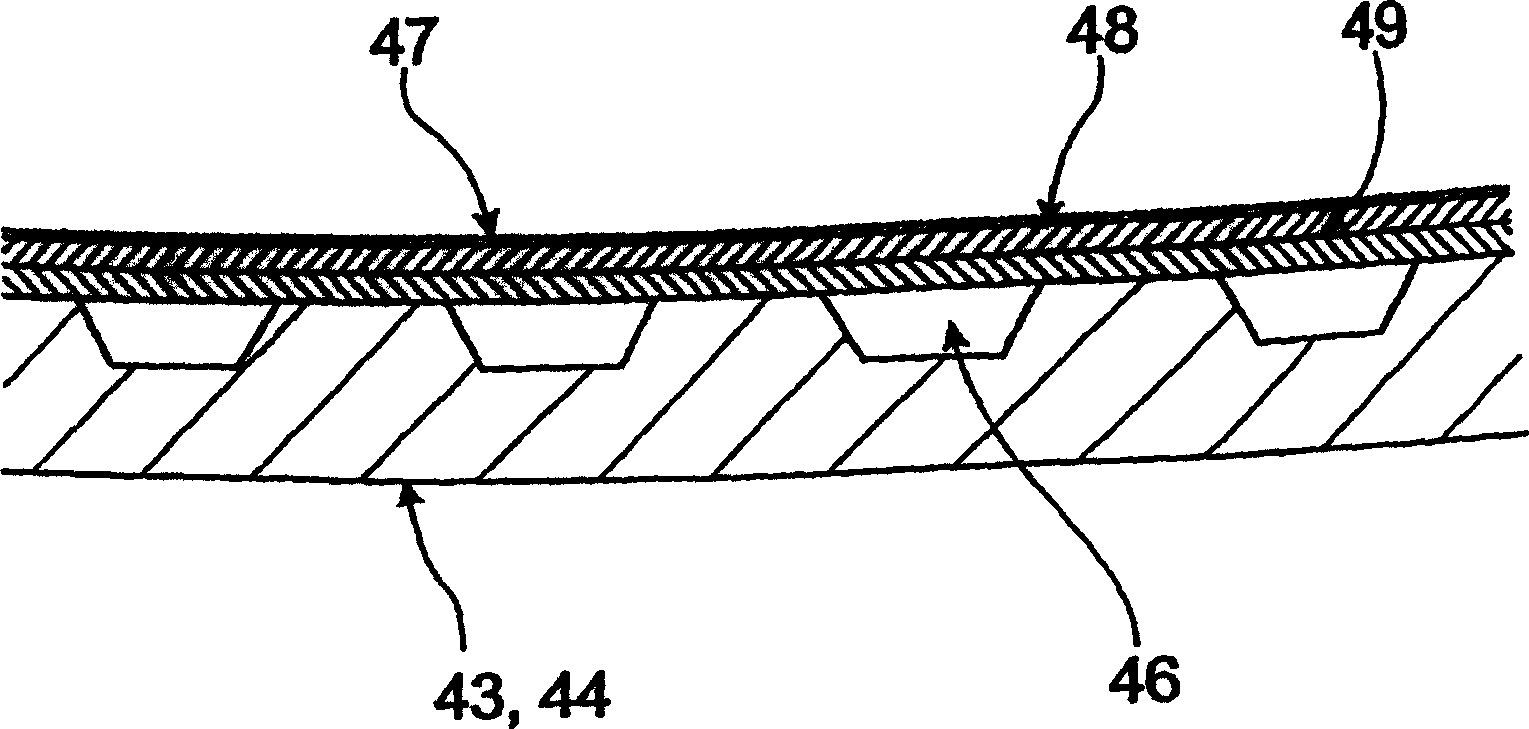

[0049] A centrifugal rotor 30, which will be described in more detail below, is mounted rotatably in the center of the housing 11 around a rotary support 31 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com