Laminated optical film, elliptically polarizing plate, and image viewing display

An optical film and polarizer technology, applied in optics, optical elements, polarizing elements, etc., can solve the problem of changing the color tone of the displayed image, and achieve the effect of wide viewing angle and viewing angle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0122] (Optical films with controlled three-dimensional refractive index (1))

[0123] For the polymer film comprising polycarbonate resin and styrene resin, PF film (55 μm in thickness): product name, manufactured by Kaneka Corporation was used. Polycarbonate resins include those derived from 2,2-bis(4-hydroxyphenyl)propane and 1,1-bis(4-hydroxyphenyl)-3,3,5-trimethylcyclohexane (blending A polymer in a ratio of 40:60 (weight ratio)). In addition, the content ratio of the styrene resin (weight average molecular weight: 10,000) in the polymer film was 20% by weight.

[0124]A heat-shrinkable film, which is a biaxially stretched polyester film, was adhered on both sides of a polymer film (PF film) via a pressure-sensitive adhesive layer. Then, the obtained film was held with a synchronous biaxial stretching machine, and stretched 1.3 times at 145°C. The obtained stretched film was transparent, and had a thickness of 60 μm, frontal retardation of 140 nm, retardation in the th...

Embodiment 2

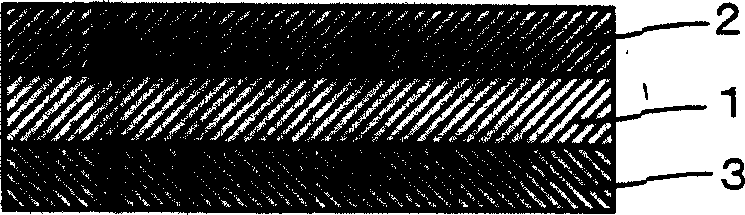

[0132] Through a layer of pressure-sensitive adhesive (30 μm thick, acrylic-based pressure-sensitive adhesive), press as Figure 5 The order of the optical film (1) / optical film (3) / optical film (2) / polarizer (P) shown in the lamination is used for the optical film (1), optical film (2) in Example 1, An optical film (3) and a polarizer (P), and an elliptical polarizer is obtained.

Embodiment 3

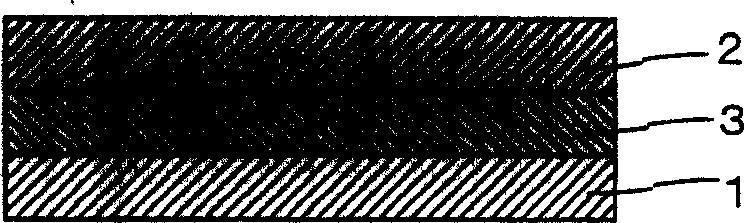

[0134] Through a layer of pressure-sensitive adhesive (30 μm thick, acrylic-based pressure-sensitive adhesive), press as Image 6 The sequence of the optical film (1) / optical film (2) / optical film (3) / polarizer (P) shown in the lamination is used for the optical film (1) in Example 1, the optical film (2), An optical film (3) and a polarizer (P), and an elliptical polarizer is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| photoelasticity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| photoelasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com