Exposure method for exposure device

An exposure method and technology of an exposure device, which are applied to the exposure device of photoengraving process, microlithography exposure equipment, optics, etc., can solve the problems of difficult application, large error, and time required for exposure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, embodiments of the exposure method of the exposure apparatus according to the present invention will be described with reference to the drawings.

[0027] The present invention is an exposure method of an exposure apparatus, which aligns a substrate having a plurality of calibration marks for positioning, and a mask having mask marks for aligning positions with the calibration marks and a mask provided with a predetermined pattern. Exposure is performed with the mask in close contact with the substrate.

[0028] First, the exposure apparatus which is the premise of an exposure method is demonstrated.

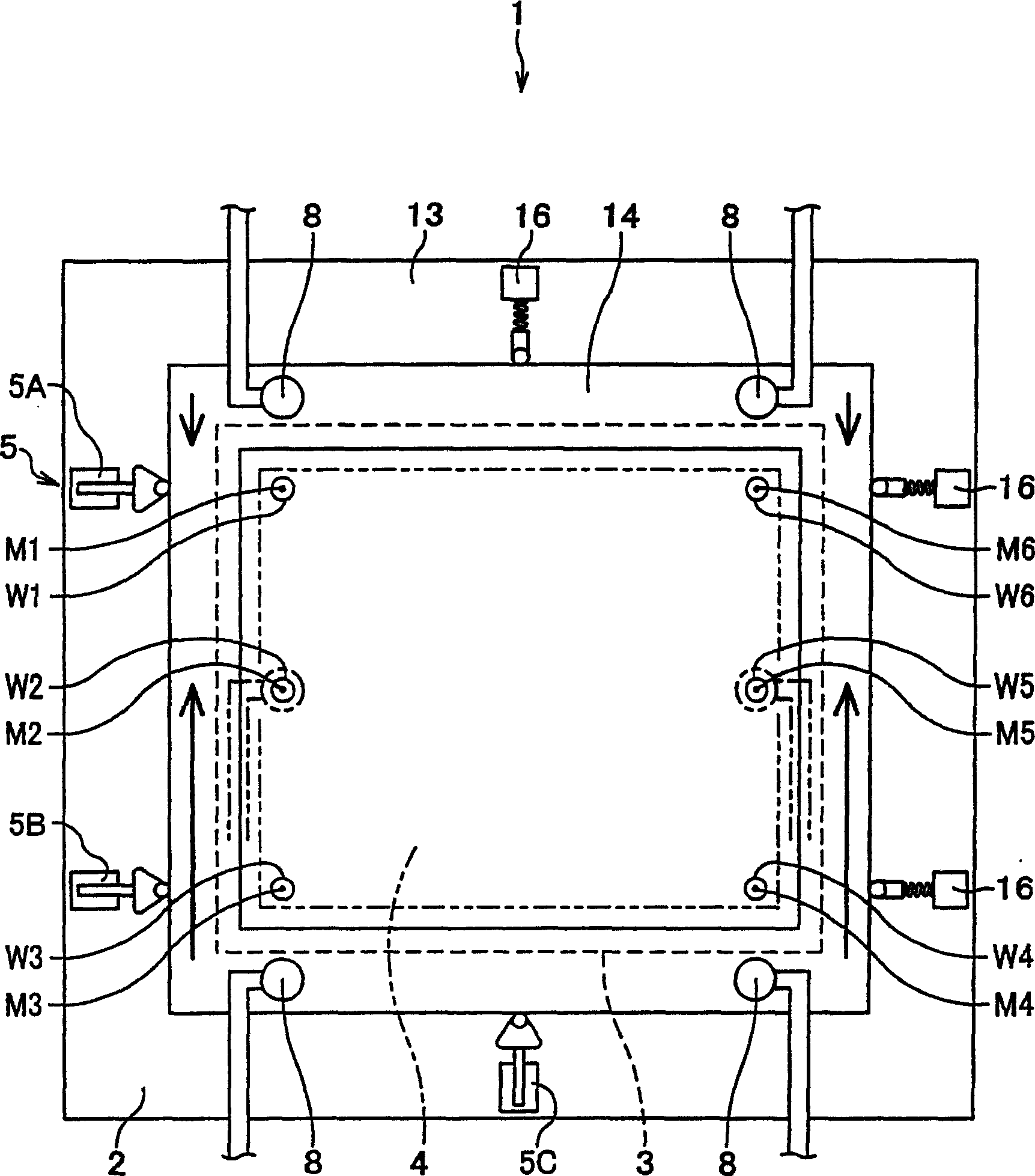

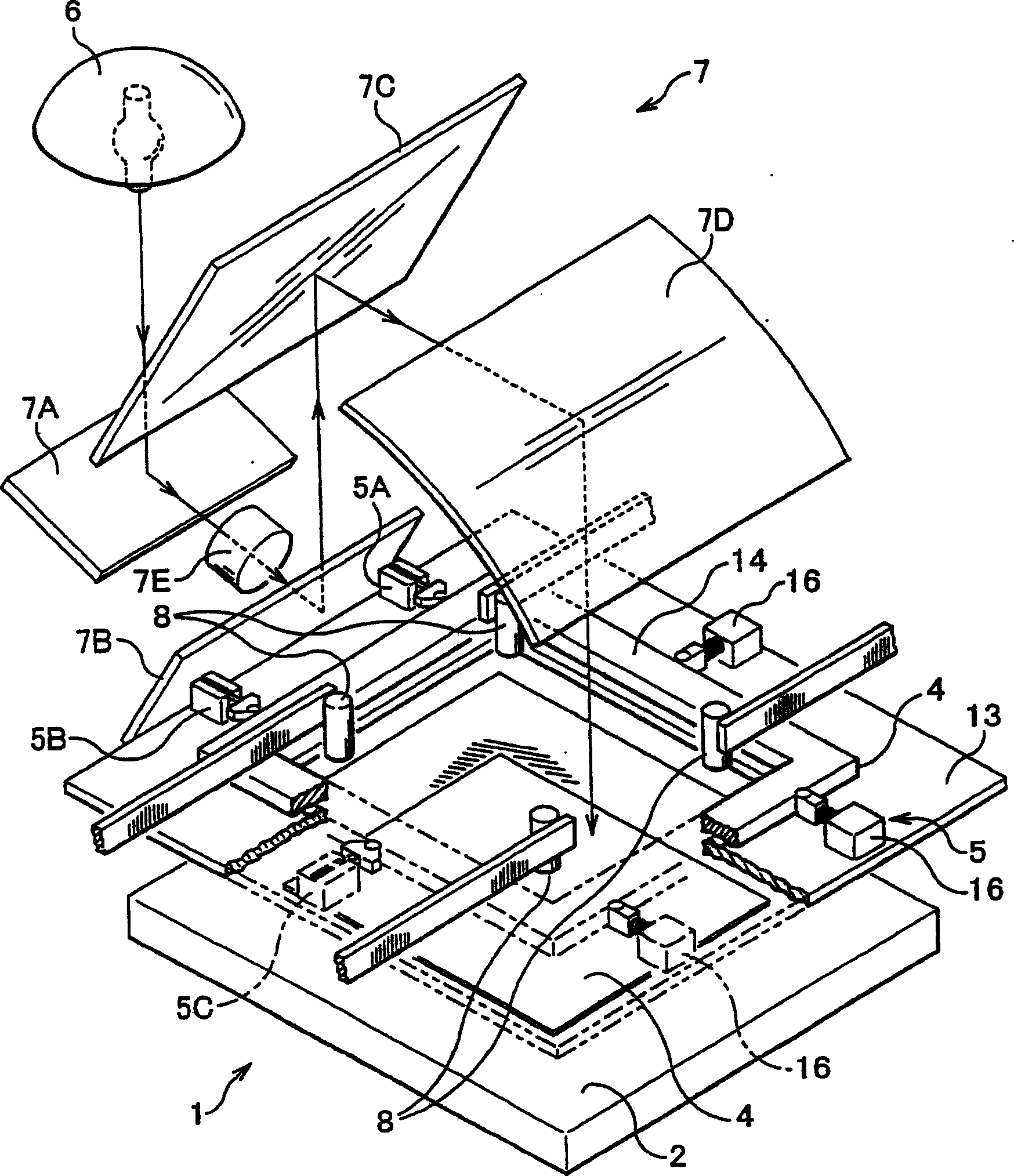

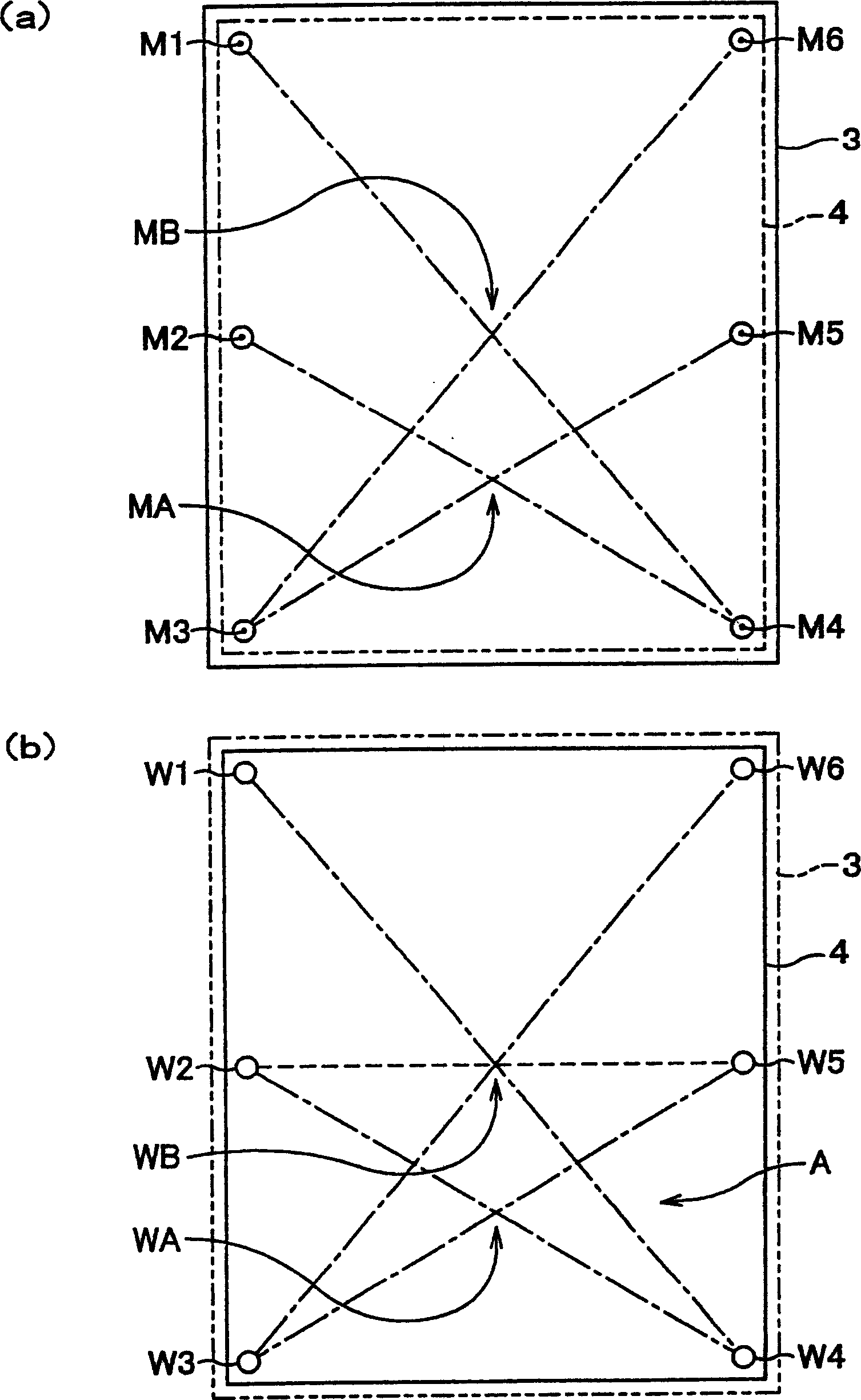

[0029] In the attached drawings, figure 1 It is a plan view showing main parts of the exposure apparatus. figure 2 It is a three-dimensional schematic diagram of the whole exposure device. image 3 (a) is a schematic diagram showing the arrangement of mask marks on the mask. image 3 (b) is a schematic diagram showing the arrangement of alignment marks on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com