Droplet inspection method and device

A liquid droplet and liquid spray port technology, applied in the droplet inspection method and device field of dripping droplets, can solve the problems of unstable brightness, cost increase, image abnormality, etc., and achieve the effect of rapid exposure of dripping images

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

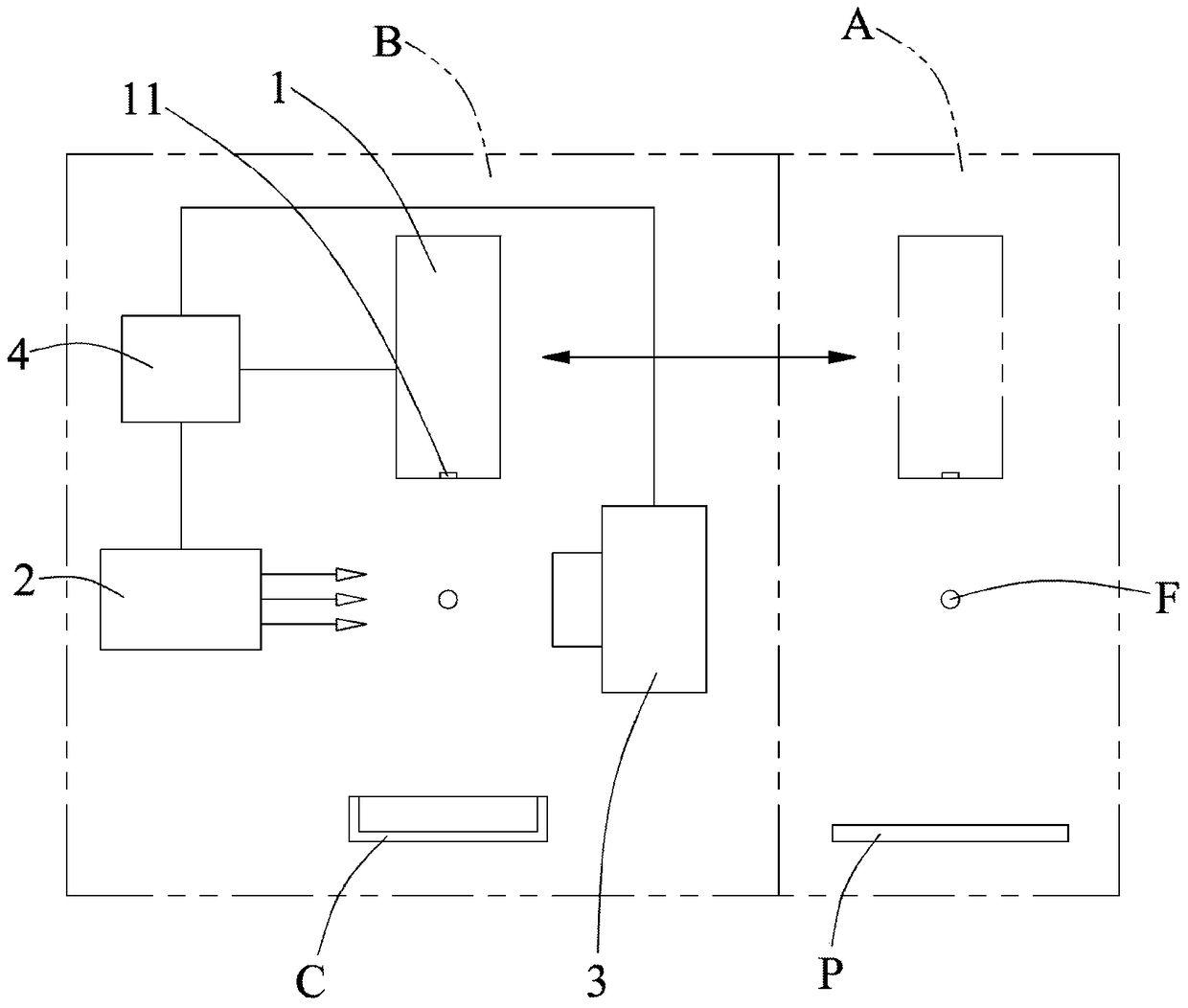

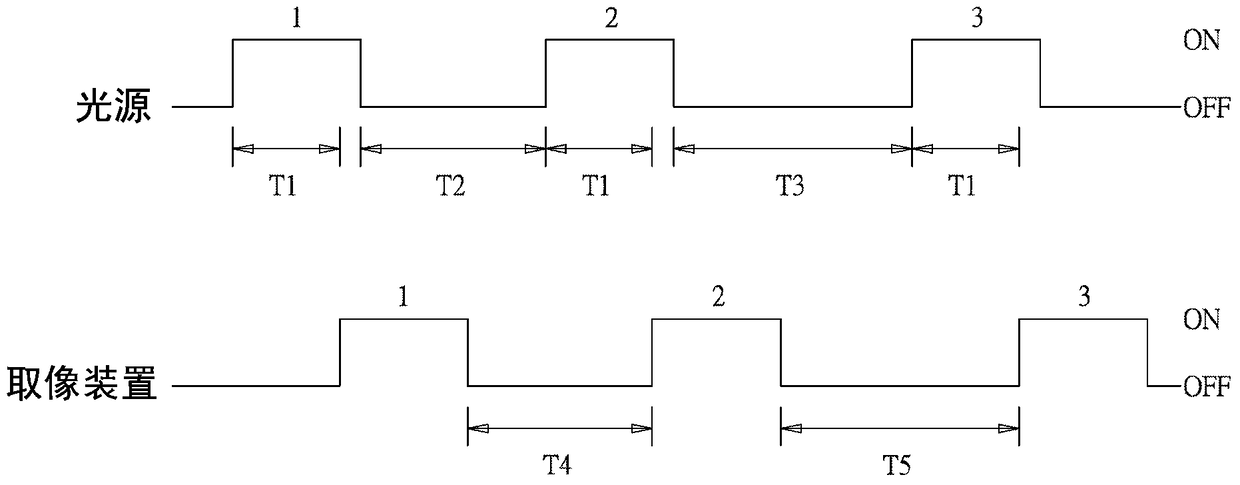

[0029] see figure 1 , the droplet inspection method in the embodiment of the present invention can be implemented using the device shown in the figure, including:

[0030] A liquid ejection head 1 is provided with a plurality of liquid ejection ports 11, and the liquid droplets F are discharged from the liquid ejection ports 11 and continue to drop until they land on the substrate P or the collection box C;

[0031] A light source 2, which is composed of LED (light emitting diode, light emitting diode), is located close to the liquid ejection port 11 of the liquid ejection head 1, and illuminates the dripping liquid droplets F;

[0032] An image taking device 3, which is a CCD (charge coupled device, charge coupled device) camera, corresponding to the light source 2, for photographing the state of the droplet F in the drop track;

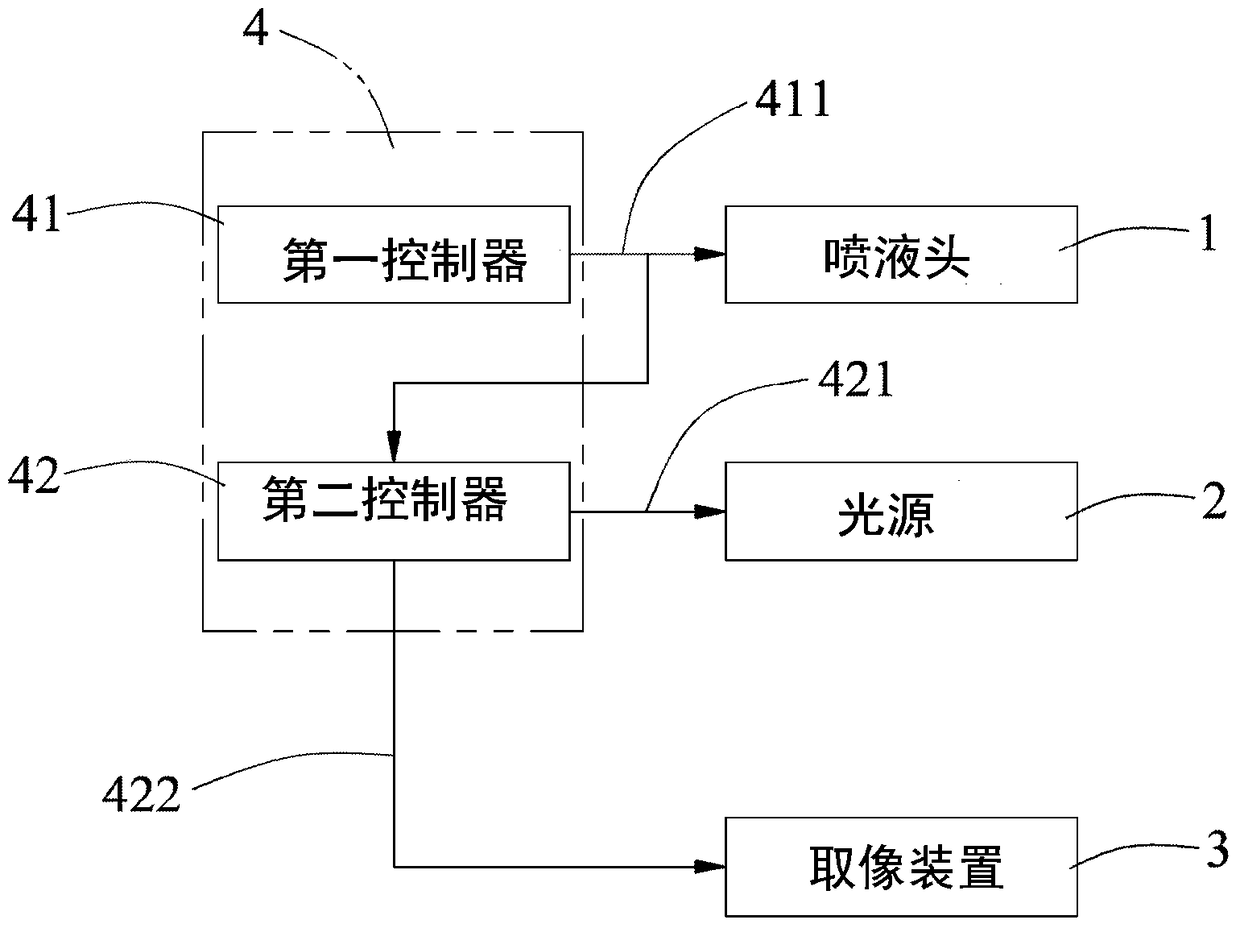

[0033] A controller 4, capable of outputting signals to control the opening and closing of the liquid ejection head 1, the light source 2 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com