Rubber cloth for plate burning and its manufacturing method

A manufacturing method and rubber cloth technology, applied in the direction of blanket covering, printing, etc., can solve the problem of high one-time investment cost of molds and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

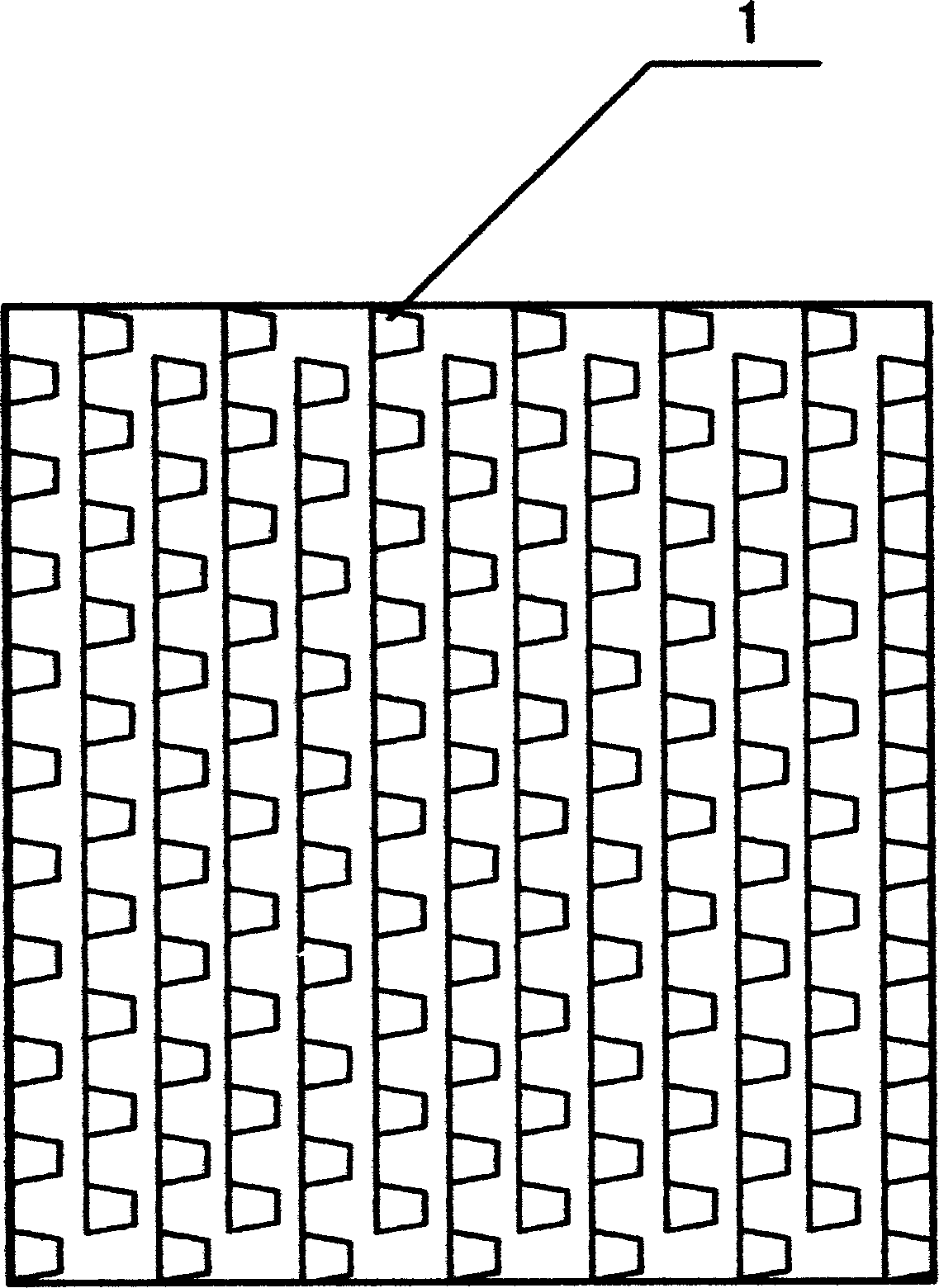

[0013] The manufacturing method of the rubber cloth for plate printing of the present invention comprises the following steps: mixing the rubber raw materials that have been compounded in a rubber mixing machine, extruding and forming a film through an extruder, and then pressing the embossed pattern on the surface of the film to obtain Finished rubber cloth: cover the surface of the film with polypropylene pattern cloth uniformly distributed with bumps, and press the two together with a flat vulcanization press. 1. The bumps 1 are connected to form a bump pattern, which is a rubber cloth for printing, such as figure 1 shown. In order to ensure the close contact between the original film and the glue layer of the plate when printing the plate, the height of the embossed pattern should be equal.

[0014] In the present invention, the molded cloth can also be made of other materials, as long as it is not bonded to the film.

[0015] According to different needs, the back of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com