Blower impeller

A blower blade and wheel hub technology, applied in the field of blower impeller, can solve the problems of difficult separation of resin and metal, poor recycling and reuse, etc., and achieve excellent effects of thermal deformation and damage rotation strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

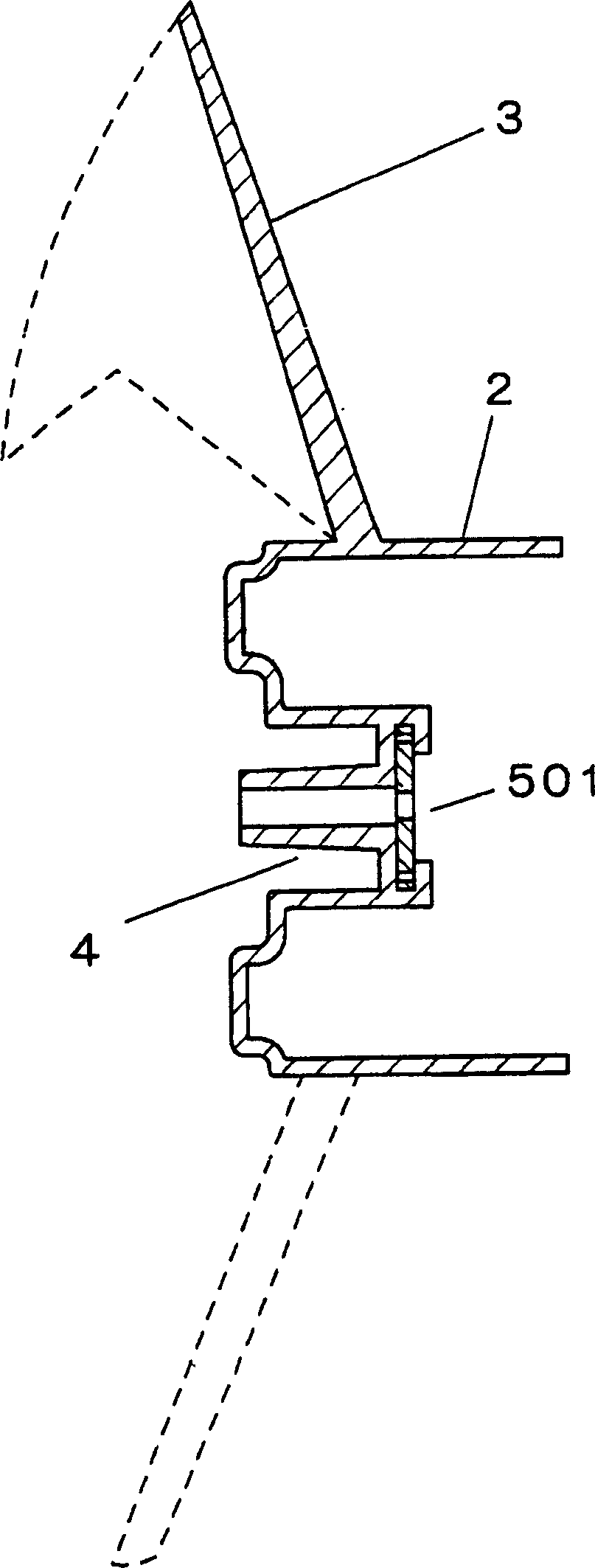

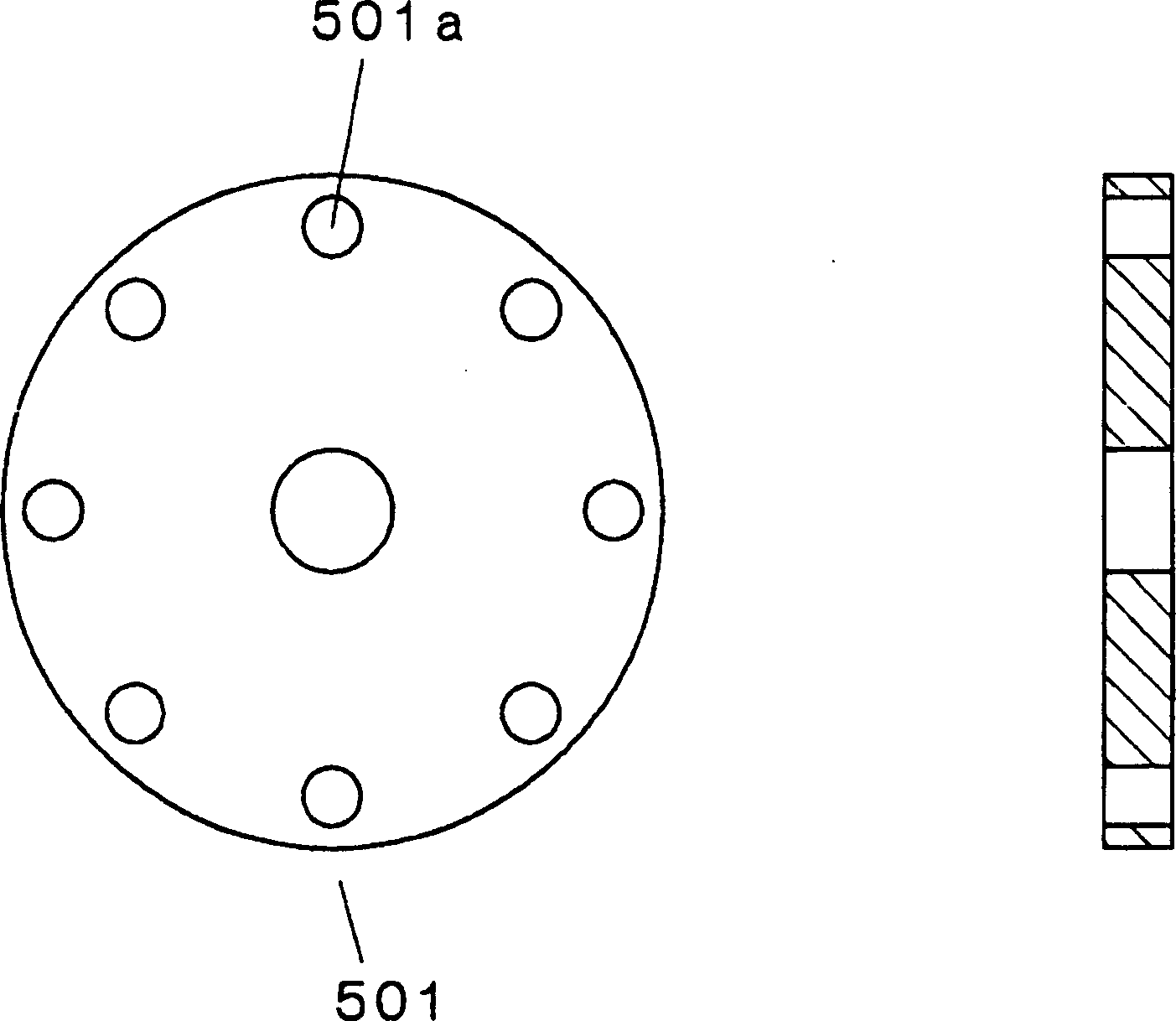

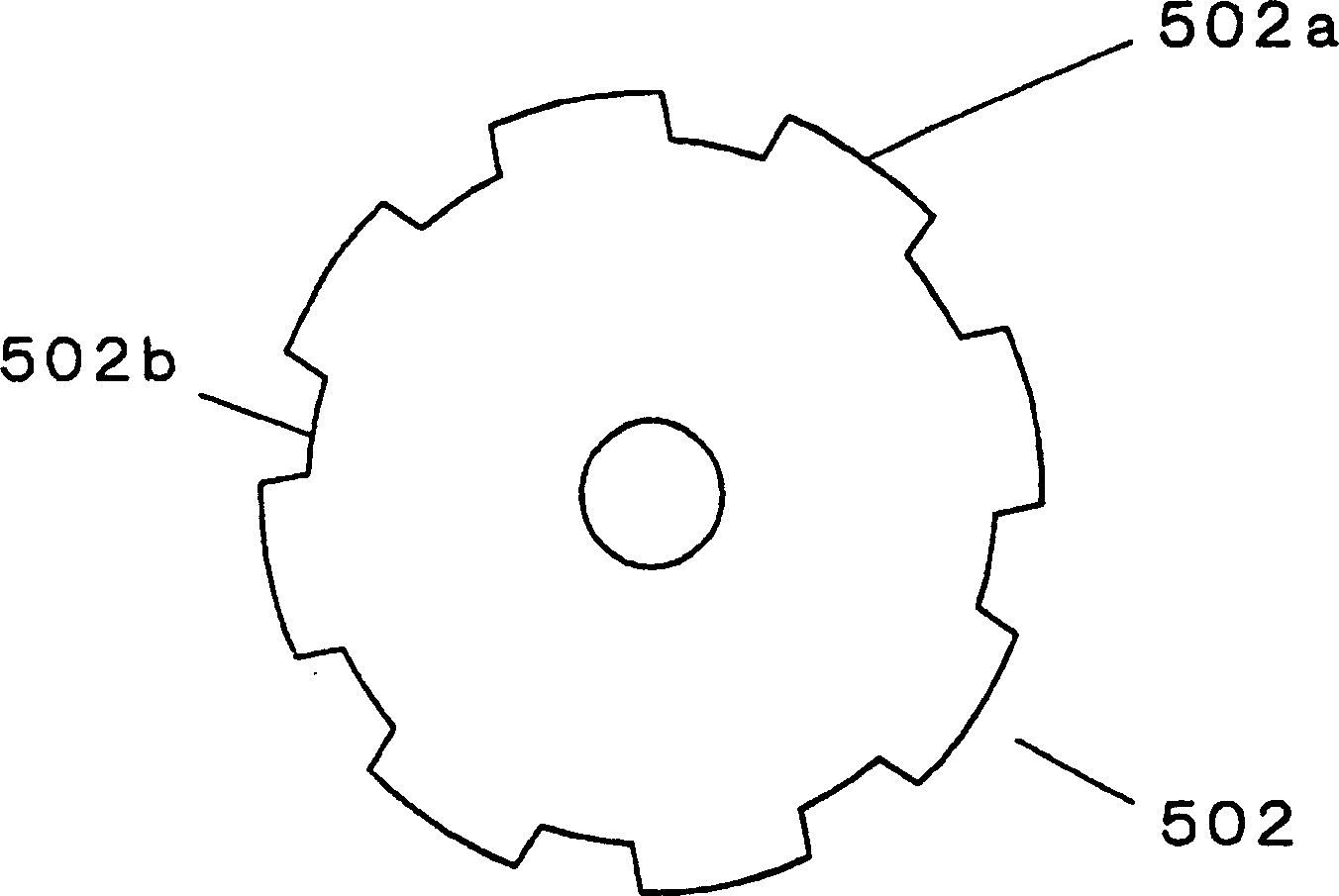

[0031] The embodiments of the present invention are described below with reference to the drawings and tables. figure 1 It is the first embodiment of the present invention. The figure shows a longitudinal cross-sectional view of a blower impeller of an air conditioner, in which a fixing member with a through hole near the outer edge is provided. figure 2 These are a plan view and a cross-sectional view of the fixing member of the first embodiment of the present invention. image 3 It is the second embodiment of the present invention, and is a plan view of a fixing member provided with tooth-like concavities and convexities on the outer edge. Figure 4 It is the second embodiment of the present invention, and is a top view of a fixing member with wave-shaped concavities and convexities on the outer edge. Figure 5 The oblique view of the appearance of the blower impeller. Fig. 6 is a longitudinal sectional view of a blower impeller of a conventional air conditioner. Figure 7 It ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com