Preparation and use of heteropolyacid catalyst carried on dealuminized super-stable gamma zeolite

A technology for loading heteropolyacids and catalysts, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as unexamined catalyst dissolution performance and has not yet occurred, and achieve obvious industrial application prospects and easy operation , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

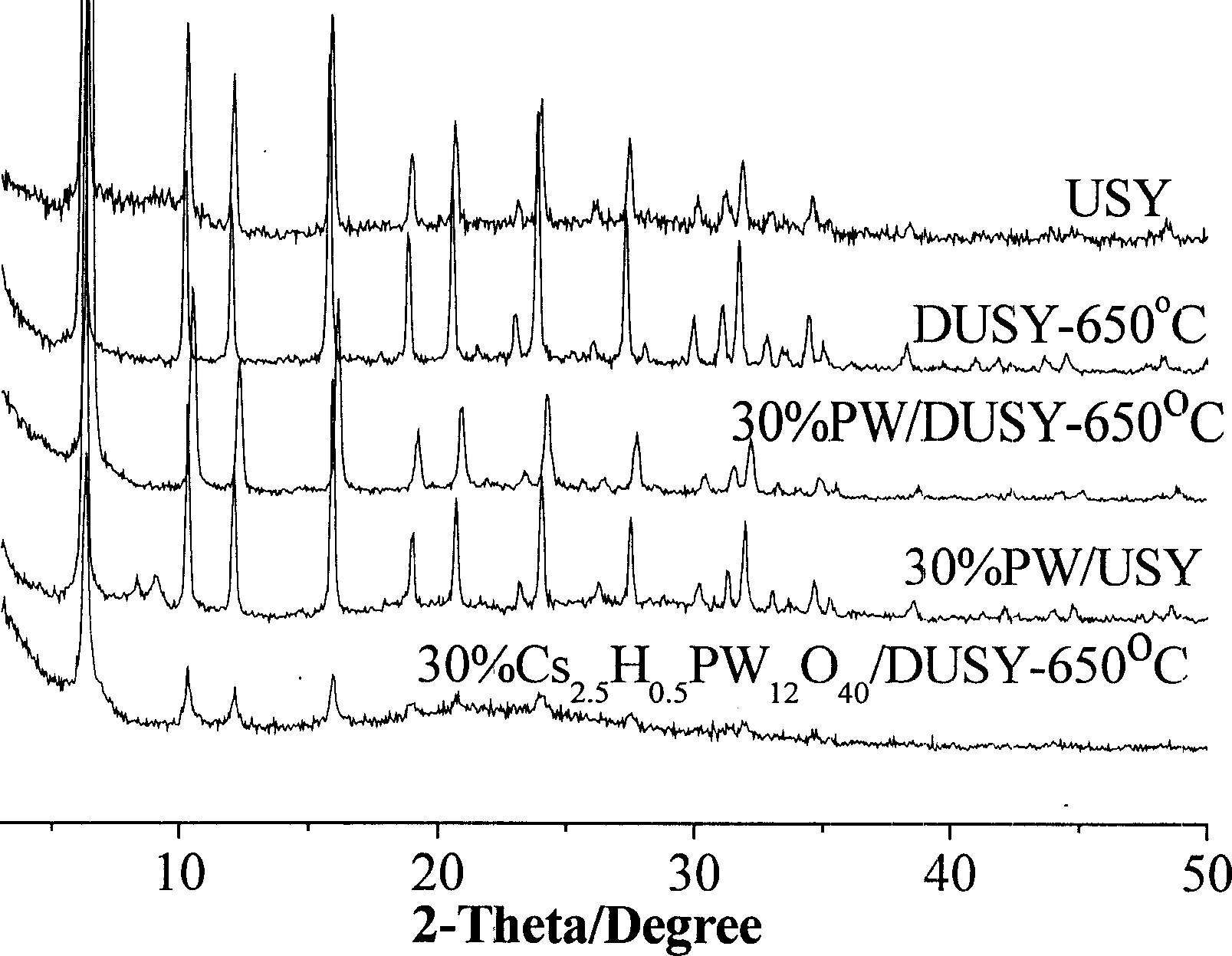

Image

Examples

Example Embodiment

[0028] Example 1

[0029] 30% Cs 1 H 2 PW 12 O 40 / DUSY-650℃ catalyst preparation

[0030] (1) Weigh 100g of USY zeolite in a crucible, add 120g of deionized water and mix it thoroughly, then place it in a muffle furnace with a lid, and quickly heat up to 650°C at a rate of 15°C / min, and calcine at this temperature for 4 hours Take out the sample, after cooling, filter and wash in 2mol / L HCl solution at 95°C for 2 hours, filter and wash with deionized water three times, dry at 110°C, and calcinate at 500°C for 8 hours to get dealuminated Ultra-stable Y zeolite (DUSY-650°C).

[0031] (2) 0.457g cesium carbonate (analytical grade) was prepared into an aqueous solution with a concentration of 0.028mol / L, mixed with the 21g DUSY-650℃ sample taken from step (1), stirred at room temperature for 12 hours, at a temperature of 95℃ and pressure The water is evaporated to dryness under the condition of 1atm, and treated in a muffle furnace at 500°C for 4 hours.

[0032] (3) Add 9.084g tungst...

Example Embodiment

[0033] Example 2

[0034] 30% Cs 1.5 H 1.5 PW 12 O 40 / DUSY-650℃ catalyst preparation

[0035] (1) The treatment conditions of the carrier are exactly the same as in Example 1.

[0036] (2) The conditions are the same as in Example 1(2), except that the dosage of cesium carbonate is changed to 0.685g.

[0037] (3) The conditions are consistent with Example 1(3).

Example Embodiment

[0038] Example 3

[0039] 30% Cs 2 HPW 12 O 40 / DUSY-650℃ catalyst preparation

[0040] (1) The treatment conditions of the carrier are exactly the same as in Example 1.

[0041] (2) The conditions are the same as in Example 1(2), except that the dosage of cesium carbonate is changed to 0.913g.

[0042] (3) The conditions are consistent with Example 1(3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com