Method for producing artificial sandstone for tertiary oil production in oil field

A technology of artificial sandstone and a manufacturing method, which is applied in the preparation of test samples, manufacturing tools, ceramic molding machines, etc., can solve problems such as the inability to truly express the permeability of underground rocks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

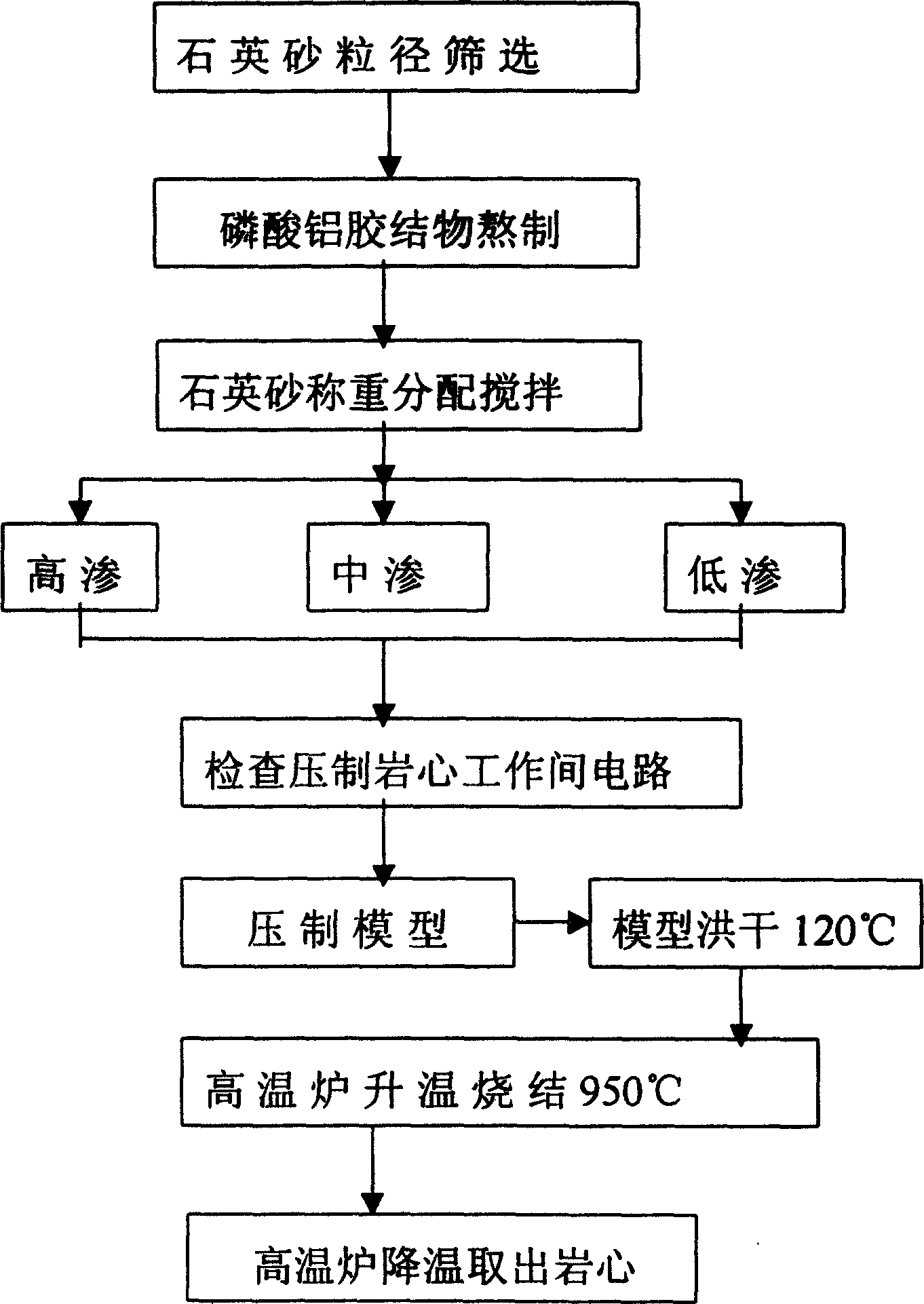

[0008] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0009] see figure 1

[0010] 1) Quartz sand is screened:

[0011] The purchased quartz sand is sieved with a standard sorting sieve, and the specific quartz sand meshes are: 30, 50, 70, 100, 300 mesh. The screening method is, if the 30-mesh quartz sand is sieved, use a combination of 30-mesh and 40-mesh standard sieves, and the remaining part is the middle part that has passed the 30-mesh sieve but not the 40-mesh sieve. The quartz sand that has not passed the 30-mesh sieve is no longer used, and the part that has passed the 40-mesh sieve is used to sort the 50-mesh quartz sand.

[0012] For the selection of clay, the purchased clay (kaolin) is dried at 150°C, and then ground into a fine powder below 300 mesh with a grinder for subsequent use.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com