Conveying system

A technology of transmission system and walking track, which is applied in the field of transmission system, and can solve problems such as difficult to use trolley 53, poor working efficiency, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be described below with reference to the accompanying drawings.

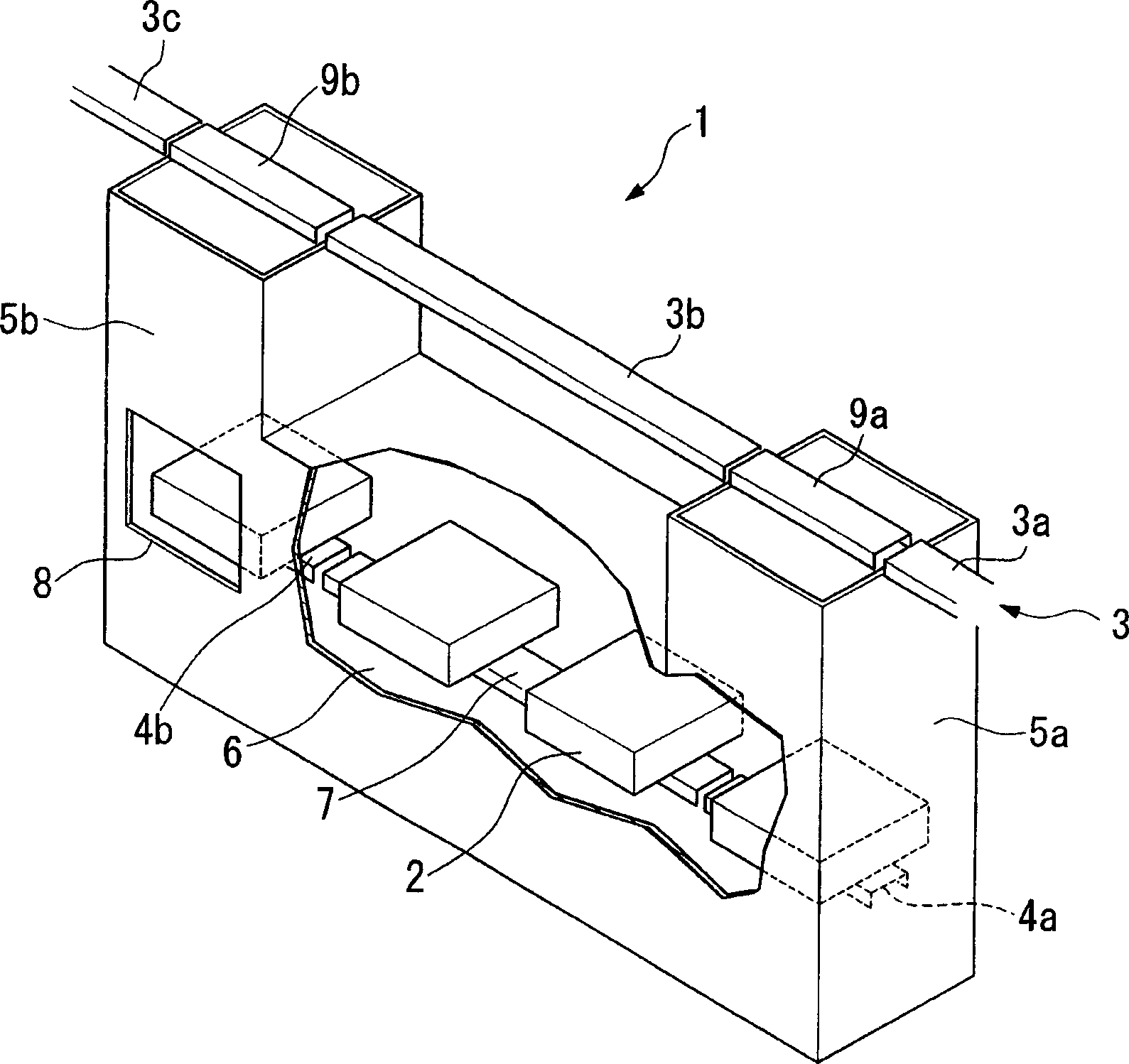

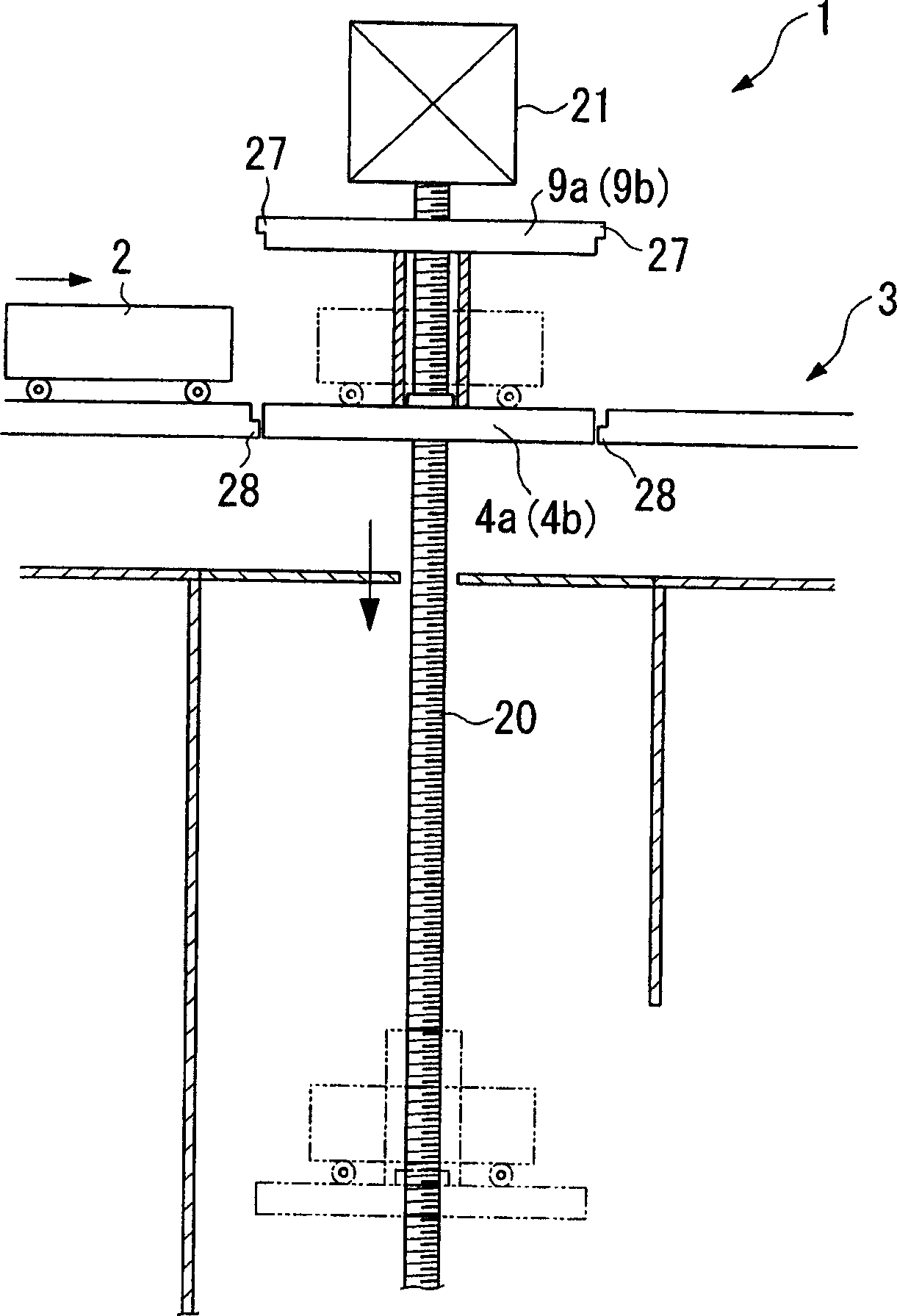

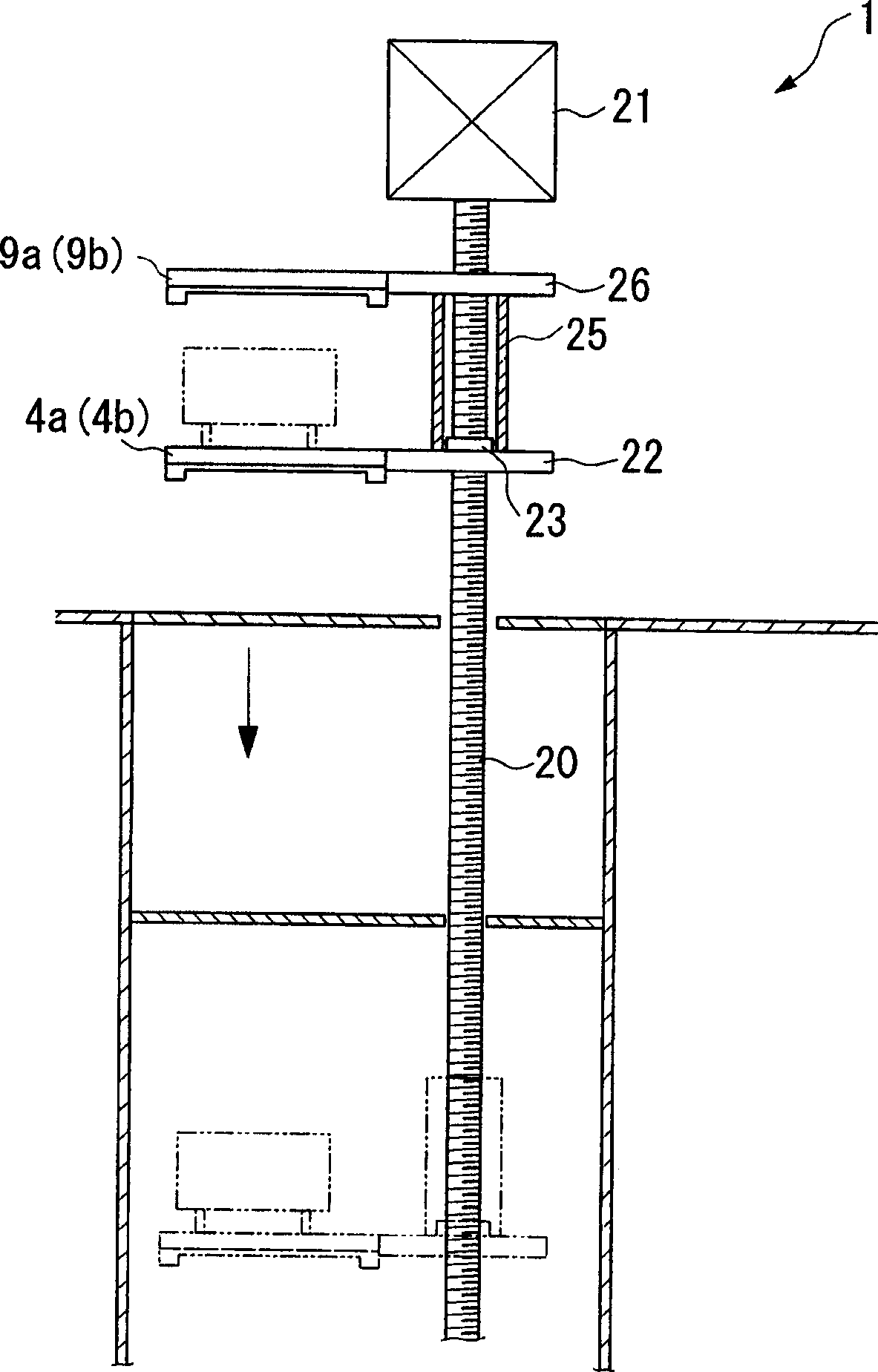

[0030] figure 1 It is a partially cutaway perspective view showing the main part of the transmission device (transmission system) that efficiently transmits various materials, samples, etc. in medical facilities, Figure 2-4 It is a front view and a side view showing the moving mechanism of the moving rail portion of the trolley.

[0031] In the delivery device given in this embodiment, as mentioned above Figure 5 As shown, a conveyor rail as a running rail is laid to pass through each room such as a consultation room, a treatment room, and an operating room in a medical facility, and a station for stopping a trolley traveling on the conveyor rail is installed in each room. The control of each trolley is automatically carried out by a control device not shown in the figure. When the sending operation is performed, the call-out control of the empty trolley that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com