Aluminium electrolytic tank combination method and its device

A scheduling method and electrolytic aluminum technology, applied in the field of modern mathematics and information, industrial electrolytic aluminum production technology, can solve the problems of low efficiency of crane distribution, waste of grade, and poor balance of class grade.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] The present invention is described in detail below with embodiment, and these explanations are only for the convenience of understanding concept of the present invention, rather than limiting protection scope of the present invention, all changes based on basic idea of the present invention are all the scope of protection of the present invention.

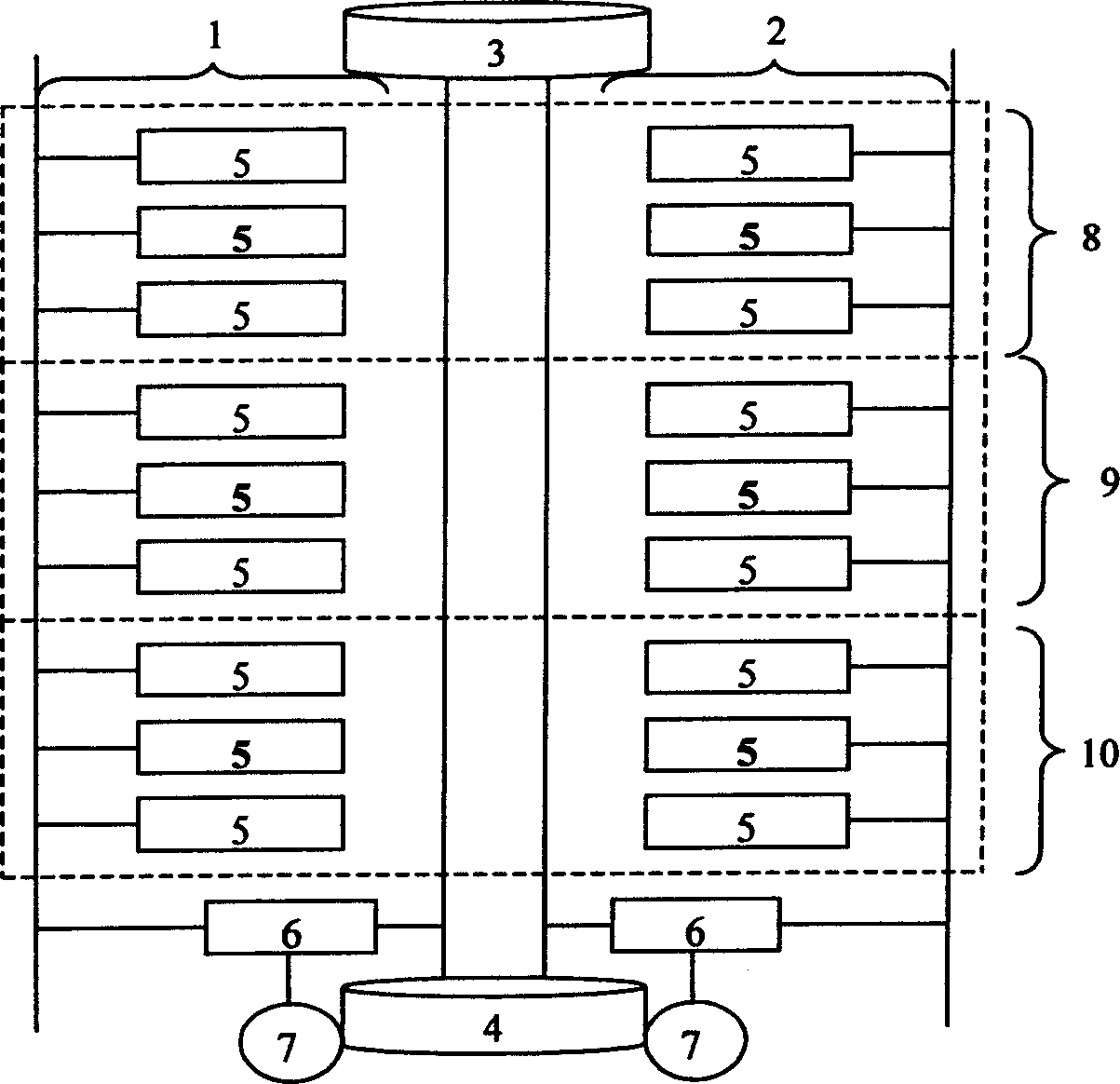

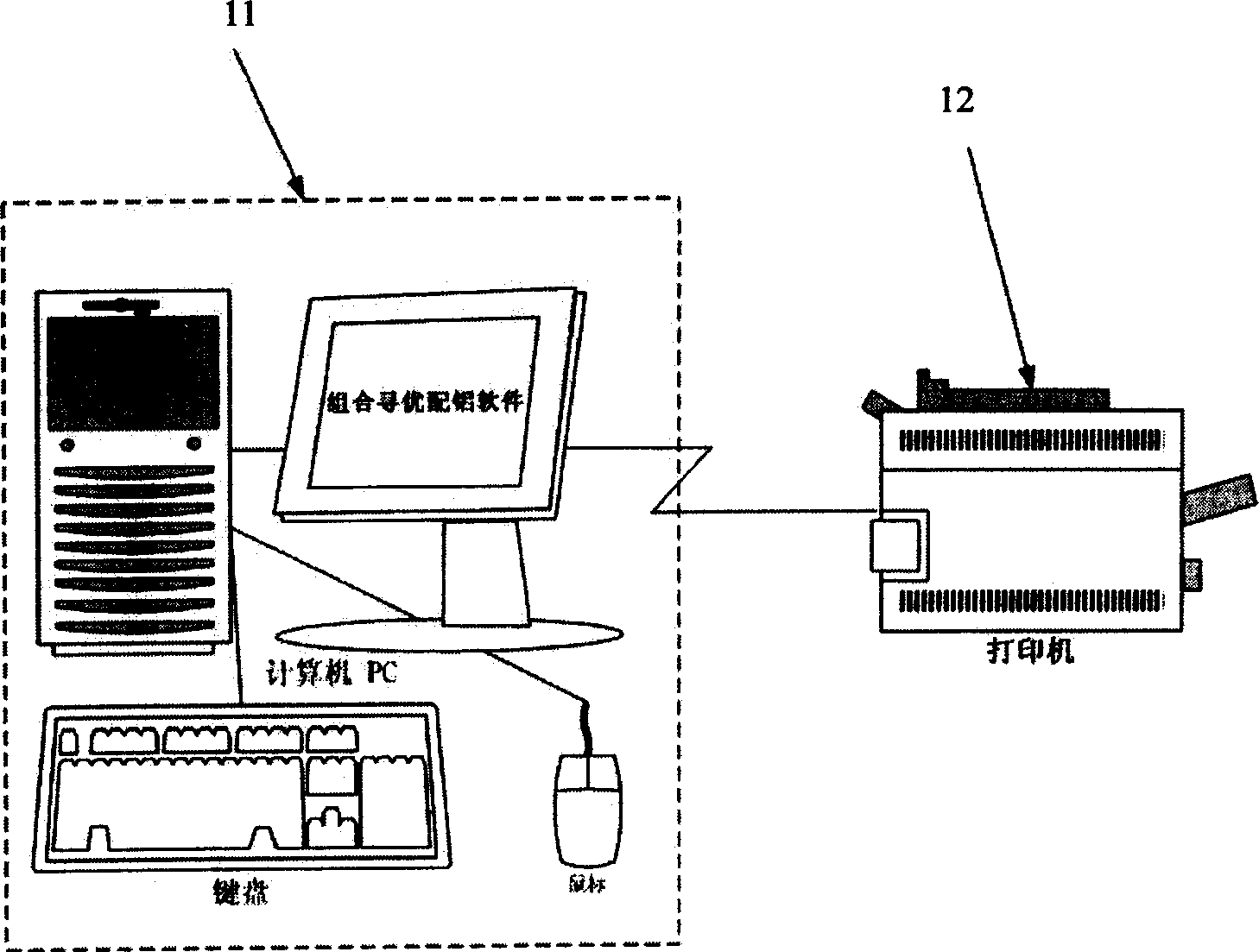

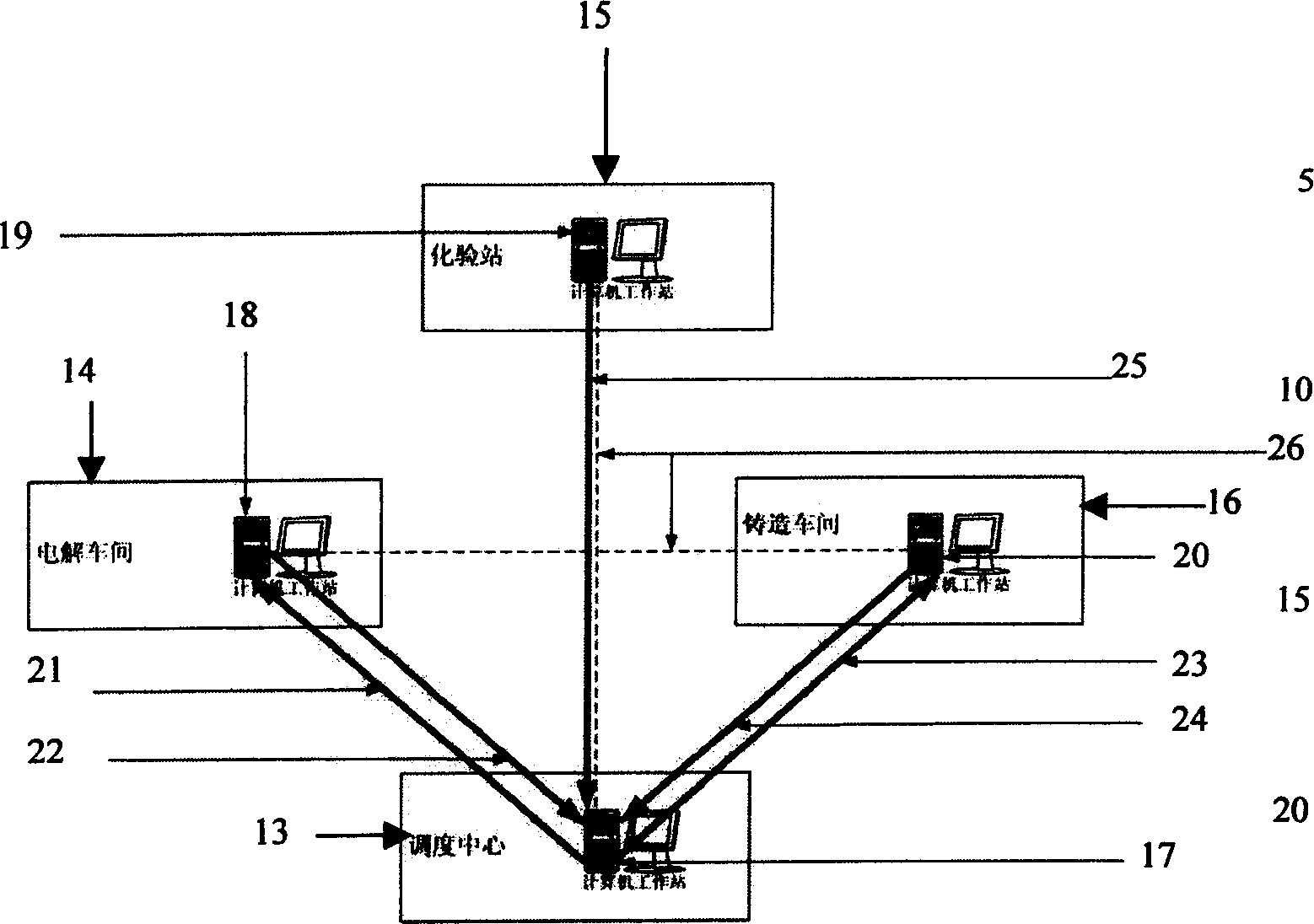

[0087] We take the production operation of three teams in one working day in an electrolytic aluminum production workshop as an example, and illustrate the electrolytic aluminum scheduling method and device provided by the present invention with reference to the accompanying drawings. The core part of the device is an electronic computer.

[0088] Among them: the electrolytic aluminum grade inspection parameters are formulated in accordance with the national GB / T 1196-2002 standard, and the following parameters should be inspected:

[0089] AL (aluminum), Fe (iron), Si (silicon), Cu (copper), Ca (calcium), Mg (magnesium), Z...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com