Method for giving cane roller batch code to organzine coiling device

A coiling device and batch technology, applied in warping machines, rewinding machines, other manufacturing equipment/tools, etc., can solve problems such as inability to manage warp beams, batch code assignment errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

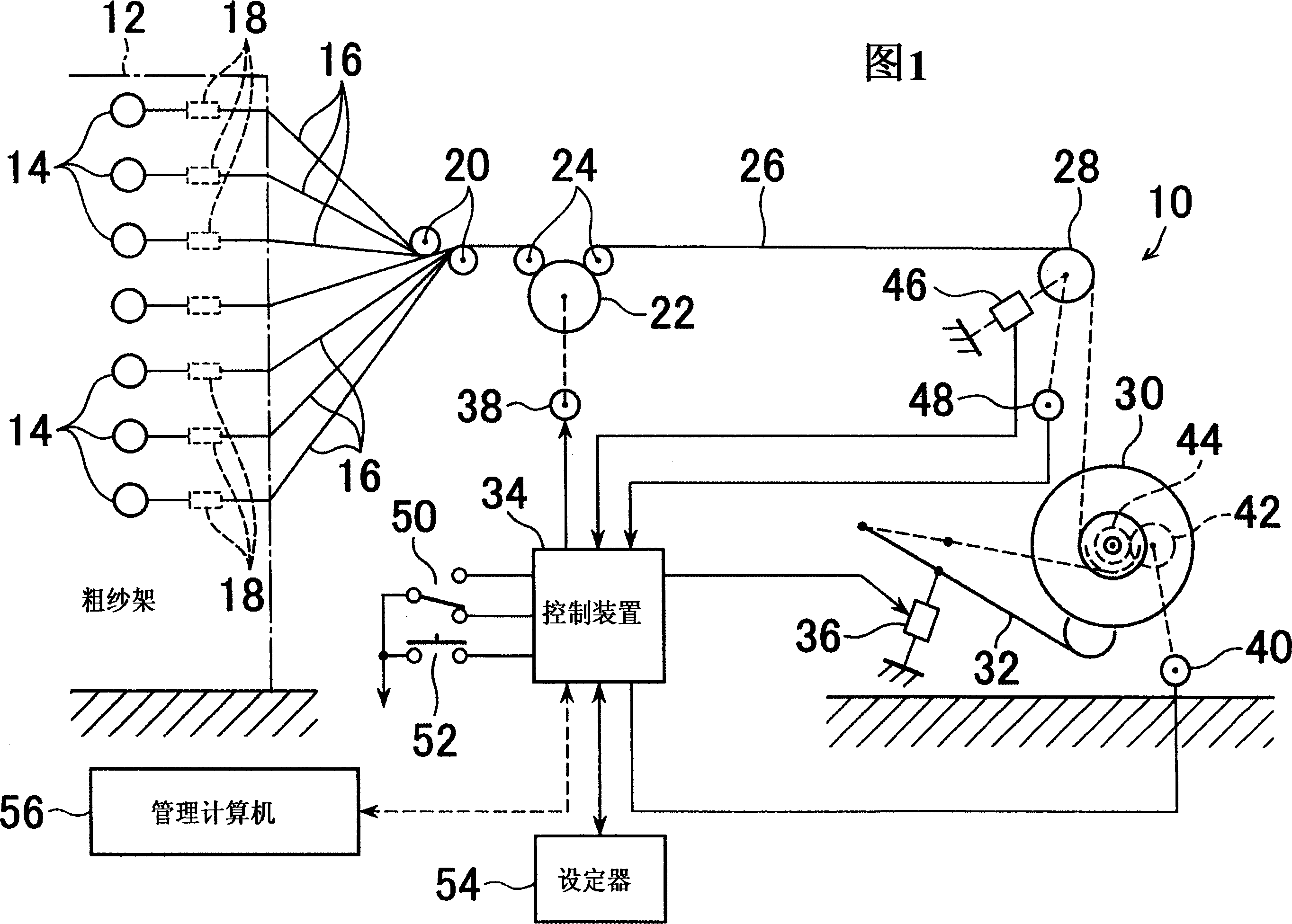

[0034] With reference to Fig. 1, warp thread take-up device 10, the many warp threads 16 that are respectively wound on a plurality of thread supply bodies 14 on the roving frame 12 are pulled out through the tensioner 18 on each warp thread, and the pulled out The warp yarns 16 are arranged side by side in sheet form with a pair of guide rollers 20, and these warp yarns 16 are sent out in the form of warp yarn sheets 26 with a take-up roll 22 and a pair of pressing rollers 24.

[0035] The warp yarn sheet 26 is wound up on the take-up warp beam 30 by the tension roller 28 which detects the tension acting on the warp yarn sheet 26 . The take-up warp beam 30 is connected to the driving motor through a connecting mechanism not shown in the figure, and is supported on a rotatable frame not shown in the figure simultaneously.

[0036] The supporting arm 32 is supported on the device frame (not shown in the figure) and can be rotated at an angle around an axis protruding horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com