Helical tube type steam trap and use in steam pipeline networks

A steam trap and spiral tube technology, which is applied in the field of spiral tube steam traps, can solve the problems of running out steam, soft water resources and heat waste, aggravating energy and resources, etc., and achieve high working reliability, convenient selection and installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

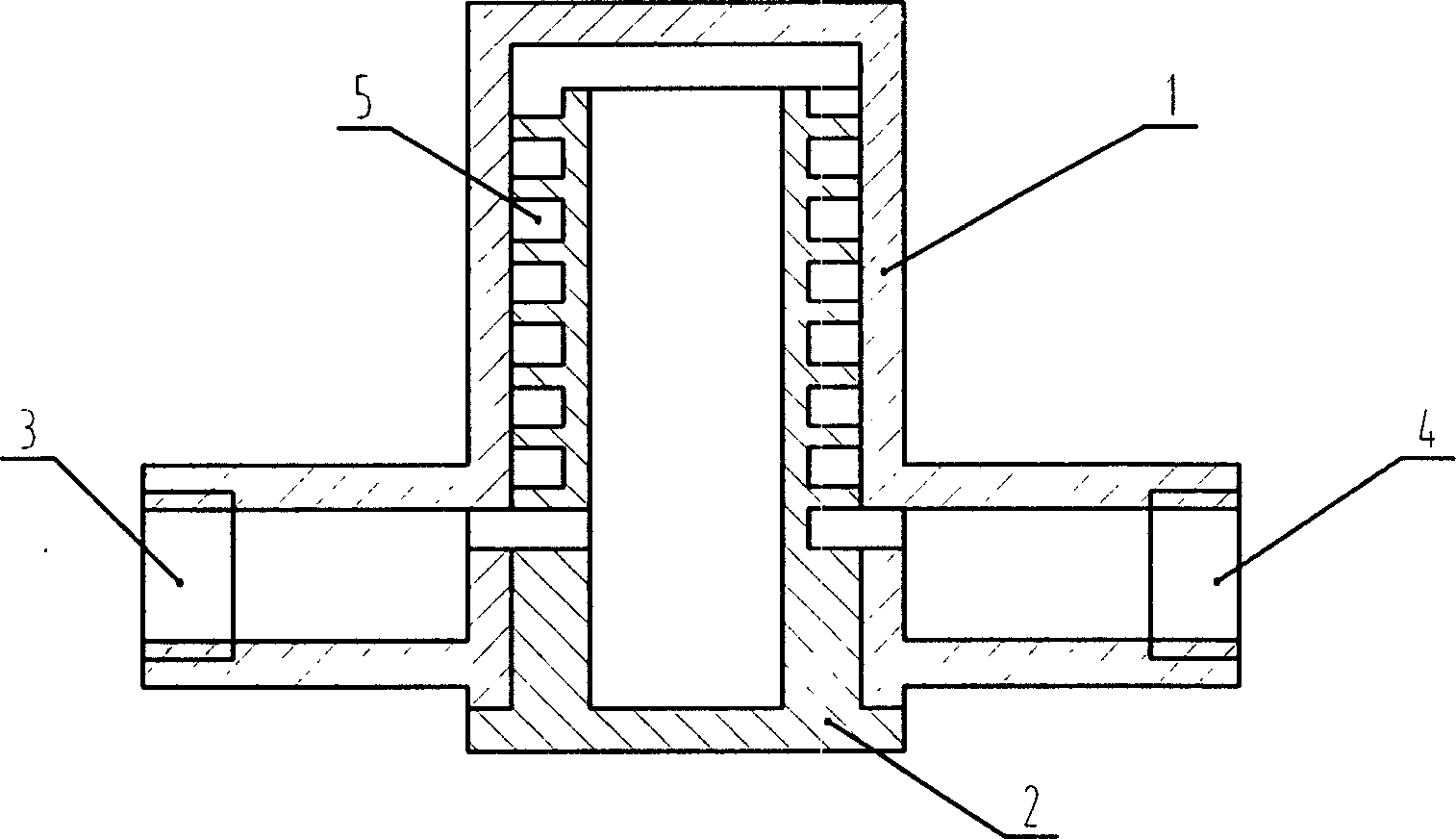

[0017] exist figure 1 Among them, the combination of the valve body (1) and the valve core (2) forms a helical tubular flow channel, in which the inlet (3) located at the lower part of the steam trap is connected to the inner cavity of the valve core (2) through the flow channel, and is located at the lower part of the steam trap. The outlet (4) on the other side is connected with the helical tube of the valve core (2), and the top of the inner cavity of the spool (2) is connected with the helical tube (5).

[0018] Steam condensate enters the valve body from the inlet (3), first enters the inner cavity of the valve core, enters the spiral tube from the top of the inner cavity, and flows into the outlet (4) from top to bottom. When the single-phase liquid steam condensate enters the steam trap, it can Flowing through the spiral tube smoothly, when steam is entrained in the condensed water, the fluid in the tube is vaporized due to the indirect heating of the steam to the spira...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com