An apparatus and method for beating and rolling a food doughbelt

A dough and food technology, applied in dough forming machinery or equipment, food science, dough sheeting machine/rolling machine/rolling pin, etc., can solve problems such as elastic recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Detailed description of preferred embodiments

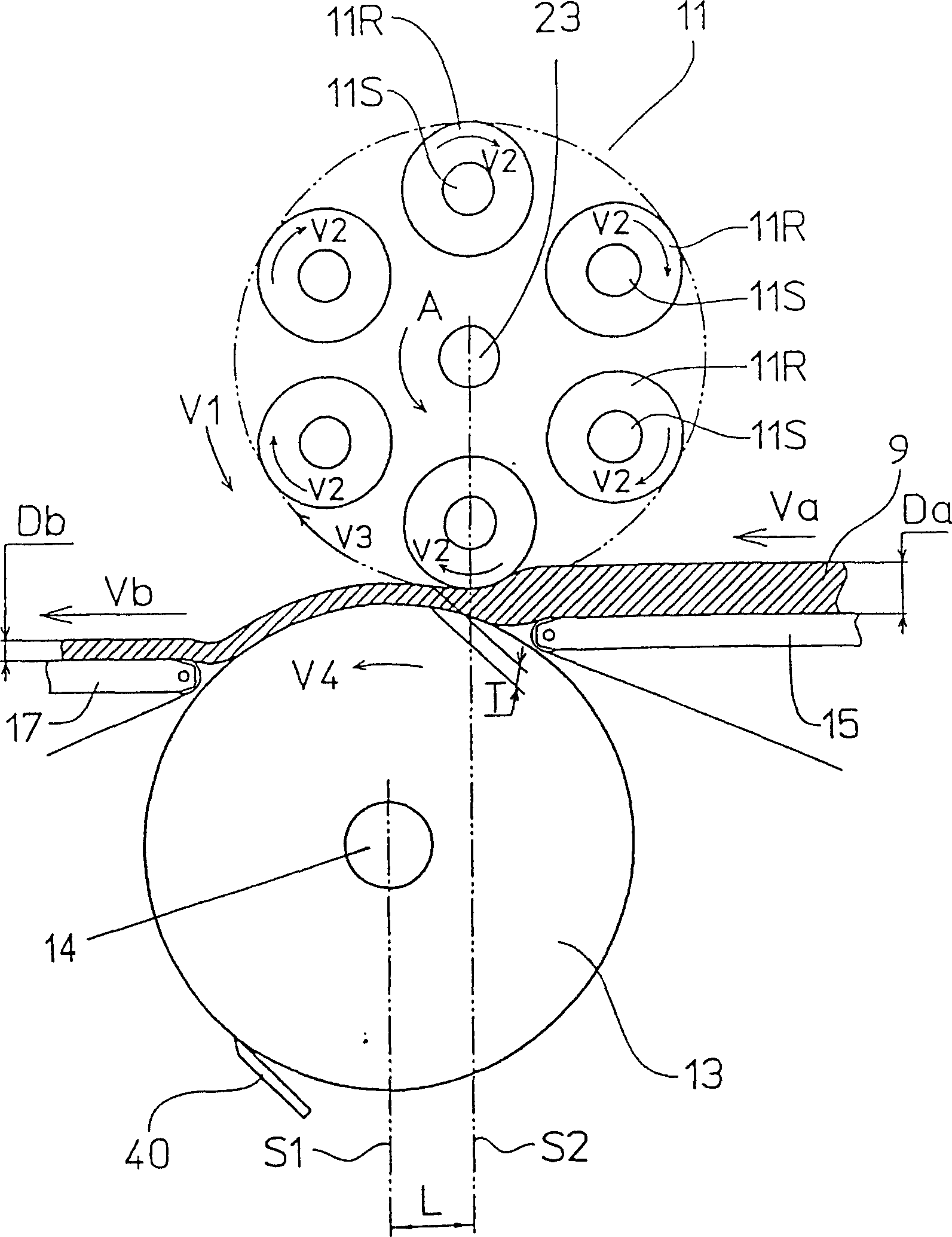

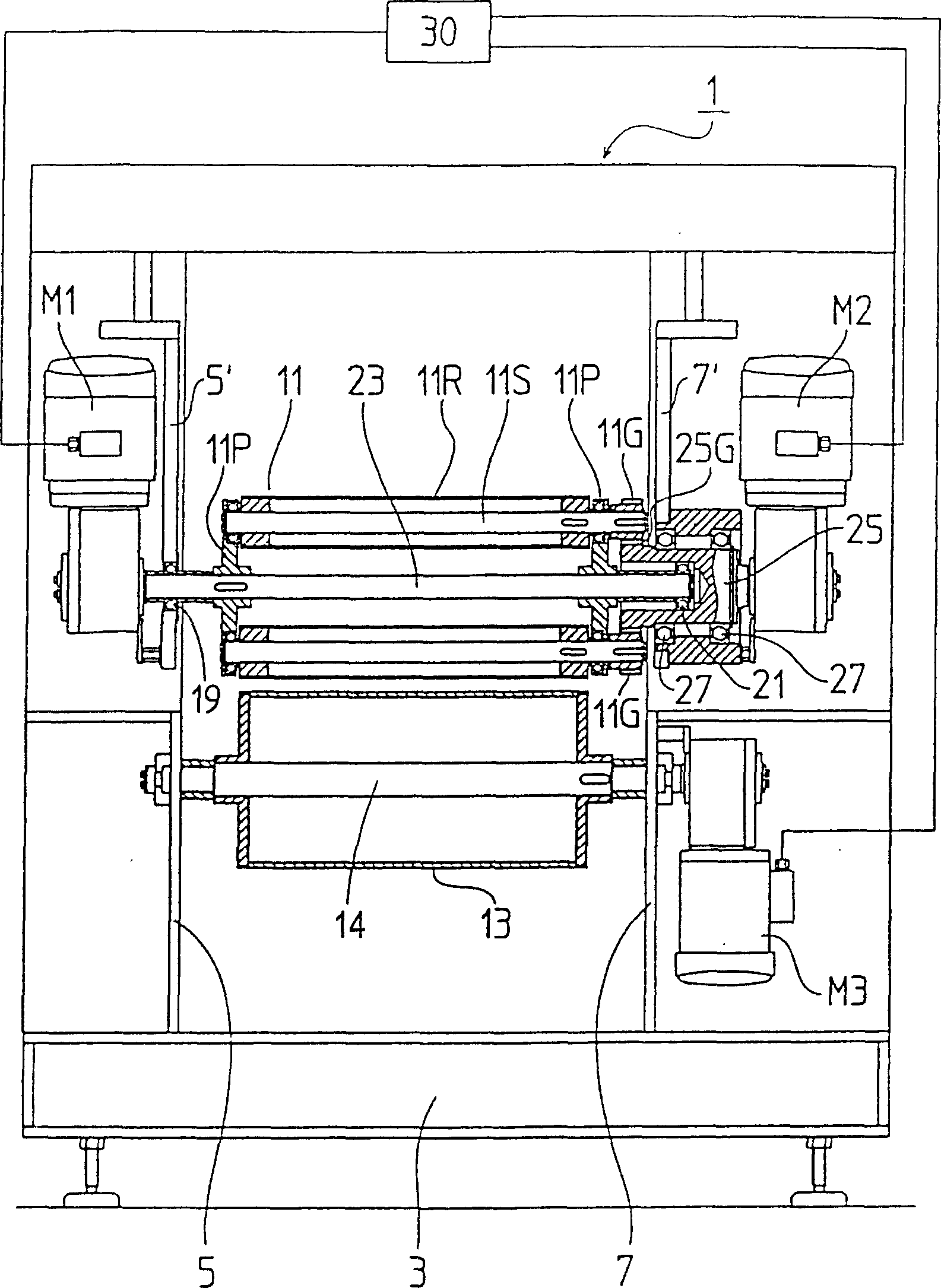

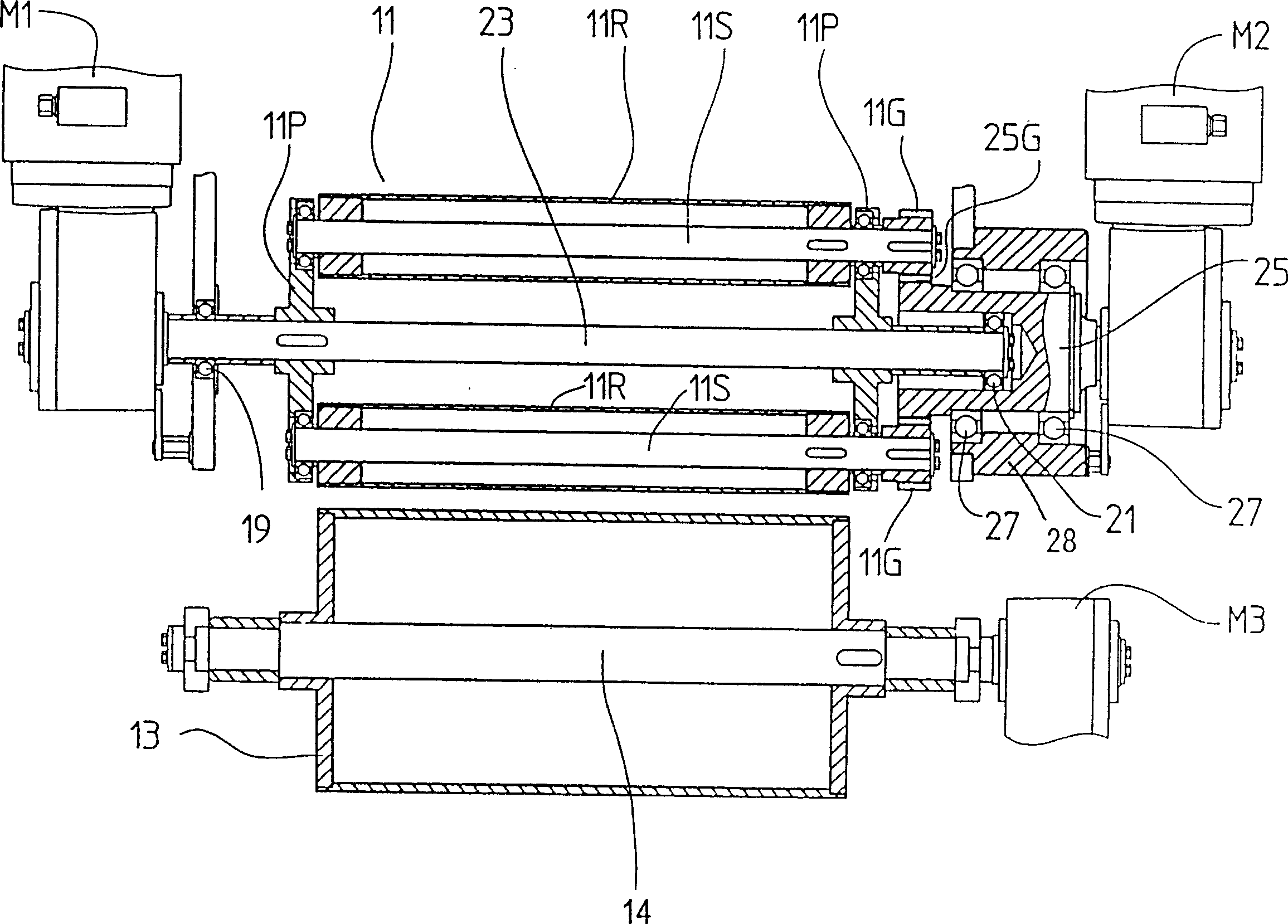

[0020] figure 1 An elevation view showing an embodiment of the invention is shown. The rolling device 1 includes a rotating element 11, such as a planetary roller mechanism arranged with rolling rollers 11R, and a rotating element 13 facing the rotating element 11, such as a large diameter conveying and rotating roller. There is a gap T between the rotating drum 13 and the planetary drum mechanism 11 with the rolling drum 11R. The dough belt 9 is conveyed to the gap T through a supply conveyor 15, and the dough belt 9 is rolled to a predetermined thickness by the rolling roller 11R in a beating or bumping shape and the rotating roller 13 in a conveying shape. An unloading conveyor 17 is provided to connect the downstream of the conveying rotating drum 13. The food dough 9 is stretched, and its thickness changes from Da to Db.

[0021] The planetary roller mechanism 11 includes a plurality of planetary rollers 11R, which are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com