Nozzle for use in hot runner mold

A hot runner and nozzle technology, applied in the field of injection nozzles, can solve the problems of high manufacturing cost and complex mold structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

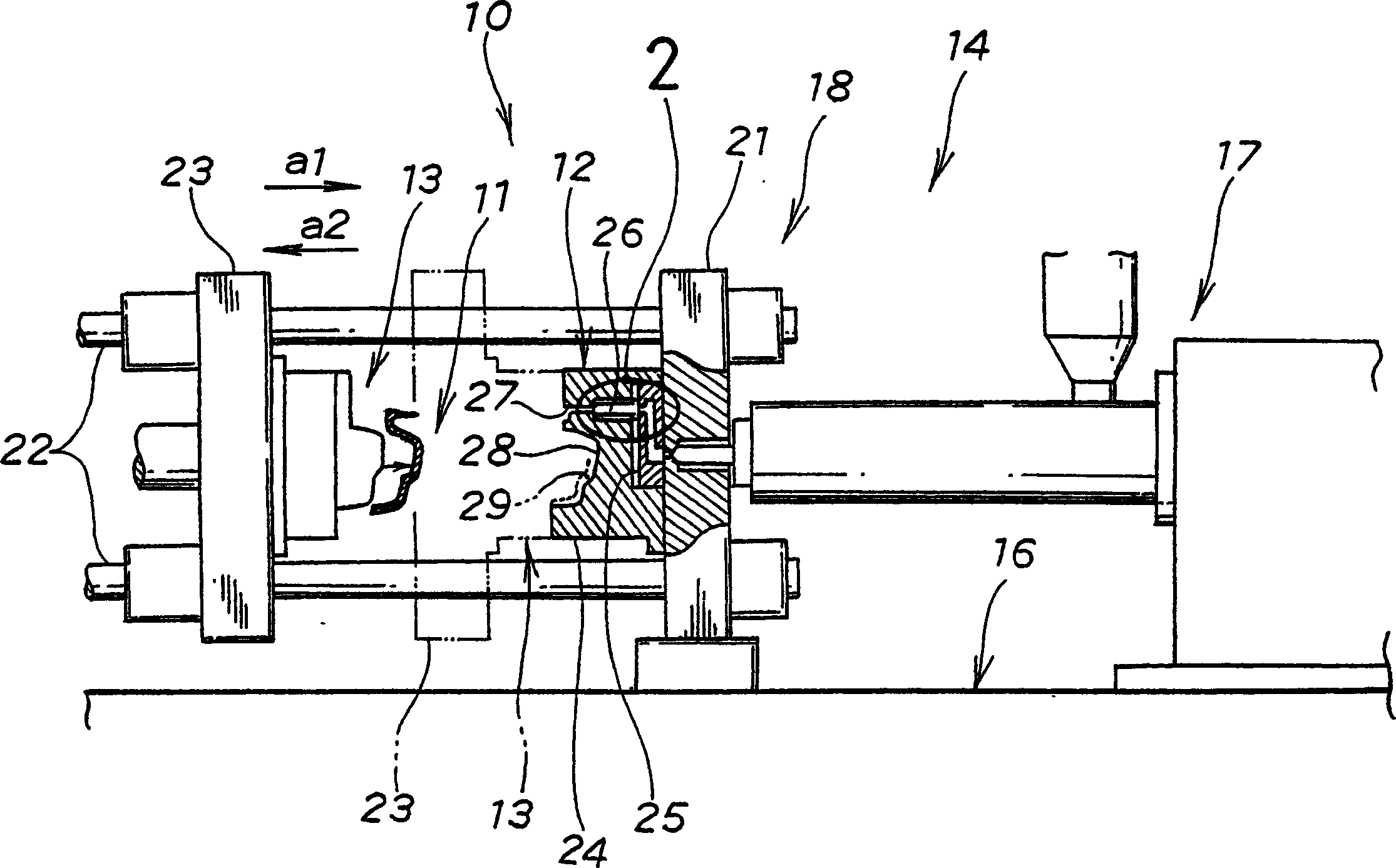

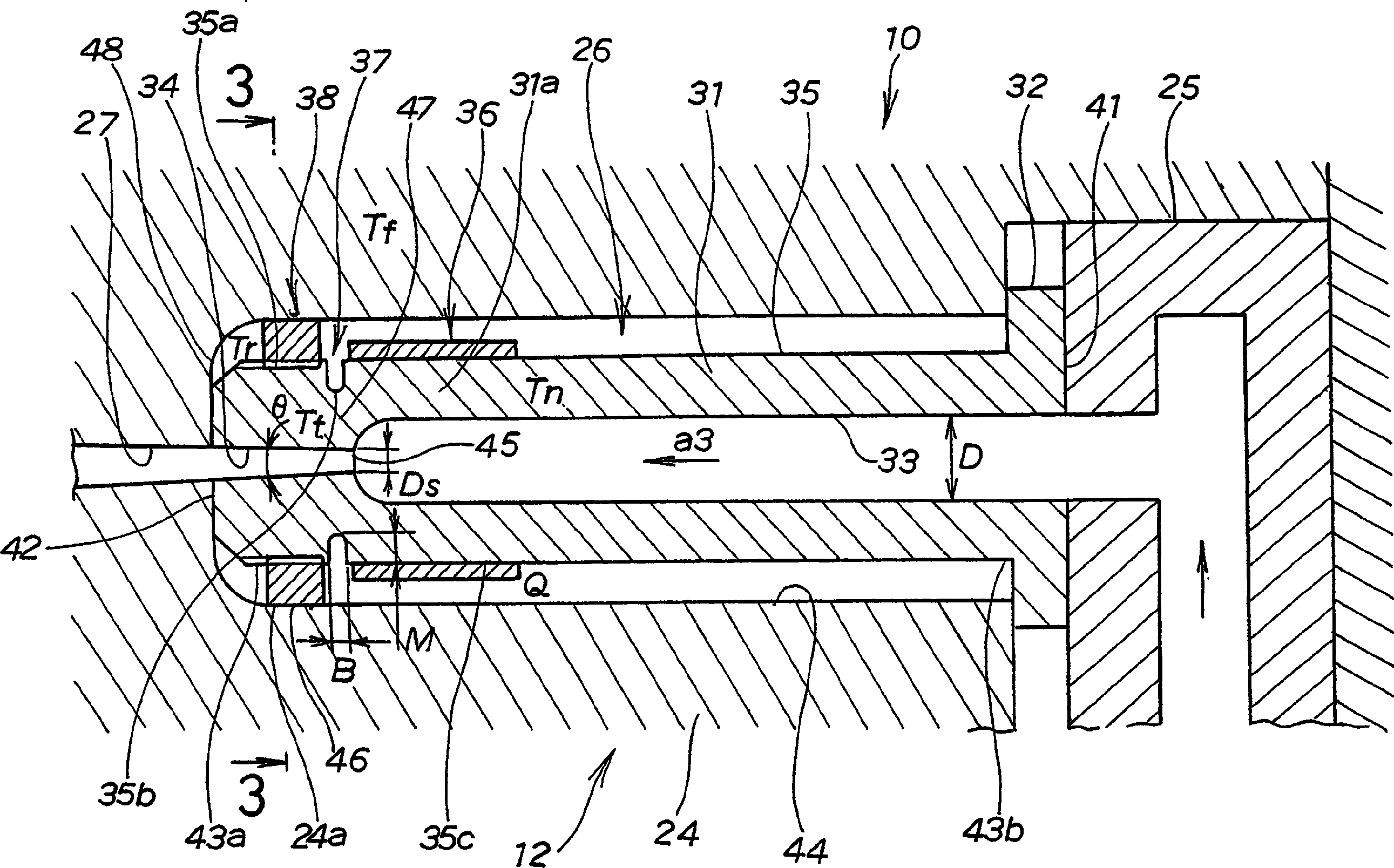

[0018] reference figure 1 , The hot runner mold 10 includes a fixed mold 12 and a movable mold 13 arranged to be engaged with the fixed mold 12. The mold 10 is installed in an injection molding machine 14 to manufacture a resin molded product 18.

[0019] The machine 14 includes: a support 16; an injection device 17 located on the support 16; and a mold clamping mechanism 18.

[0020] The mechanism 18 includes a fixed pressing plate 21, a connecting rod 22 mounted on the pressing plate 21, and a movable pressing plate 23 slidably mounted on the connecting rod 22. The movable pressing plate 23 is slidable in the direction indicated by the arrow a1, so that the movable mold 13 mounted on the pressing plate 23 is moved to the closed position shown by the two-dot chain line. In this closed position, the mold 13 is clamped to the fixed mold 12 by a predetermined pressure applied thereto. The movable platen 23 can also slide in the direction shown by the arrow a2, thereby moving the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com