Small size honeycomb structural member spot welding movable electrode and welding method

A technology of movable electrodes and small honeycombs, which is applied in the direction of electrode characteristics, welding equipment, resistance welding equipment, etc., can solve the problems of unfixed length of electrodes inserted into the honeycomb, unstable welding quality, high electrode cost, etc., and achieve good appearance and good welding The effect of high point quality and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

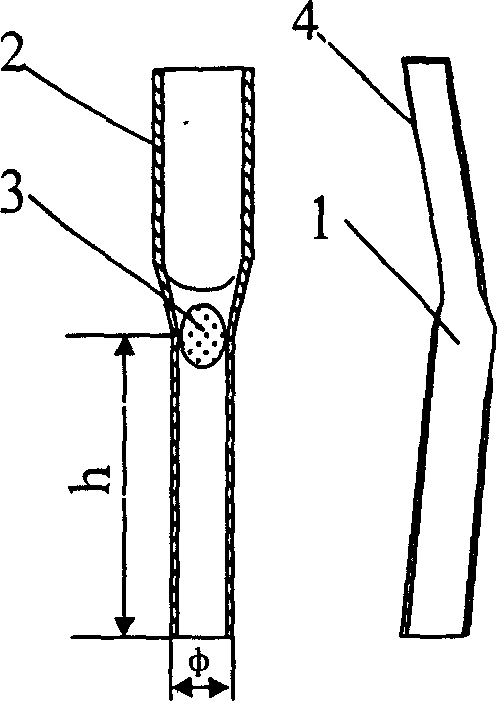

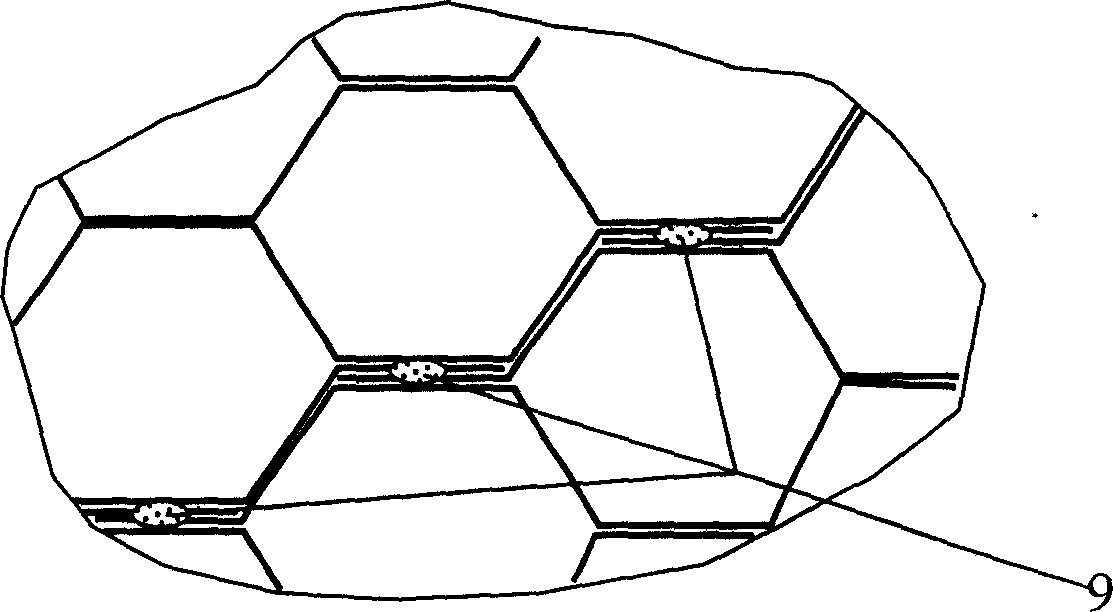

[0031] refer to figure 1 . The movable electrode is made of suitable high-strength enameled wire, which is processed into a figure 1 The active electrodes are shown. After the electrode is formed, the insulating varnish on its pressurized conductive surface 4 and welding contact surface 3 parts can be carefully removed. For example, image 3 For the honeycomb part shown, the diagonal size of the honeycomb is 1mm, and the high-strength enameled wire of φ0.7mm can be used to make the movable electrode; the diagonal size of the honeycomb is 2.0mm, and the high-strength enameled wire of φ1.6mm can be used to make the movable electrode electrode.

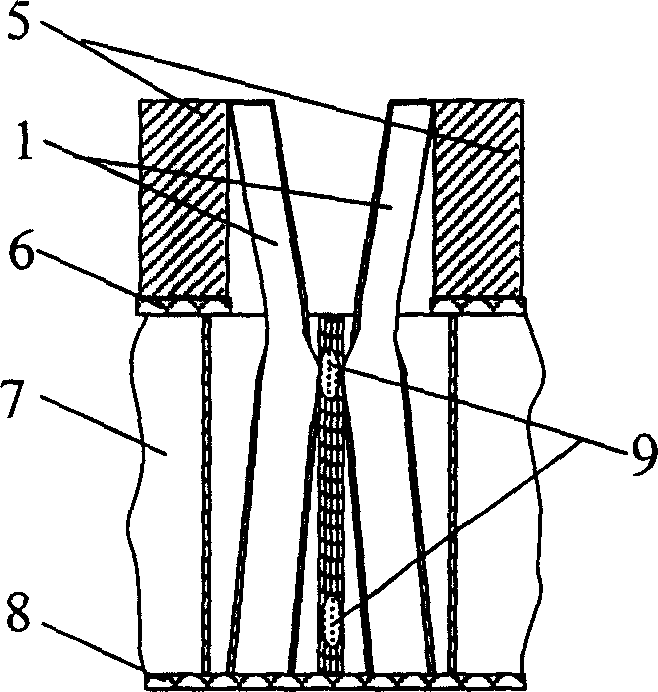

[0032] figure 2 Schematic diagram of welding for aero-engine honeycomb components. When welding, a layer of insulating plate 8 is placed on the bottom of the honeycomb member 7, and a pair of movable electrodes 1 are pressed figure 2 As shown, insert into the two honeycombs to be welded, stick a layer of insulating thin plate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com