Method of forming junction isolation active assembly

A technology of active components and junction insulation, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., and can solve the problems of complex trench process, high cost, and affecting the reliability and quality of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

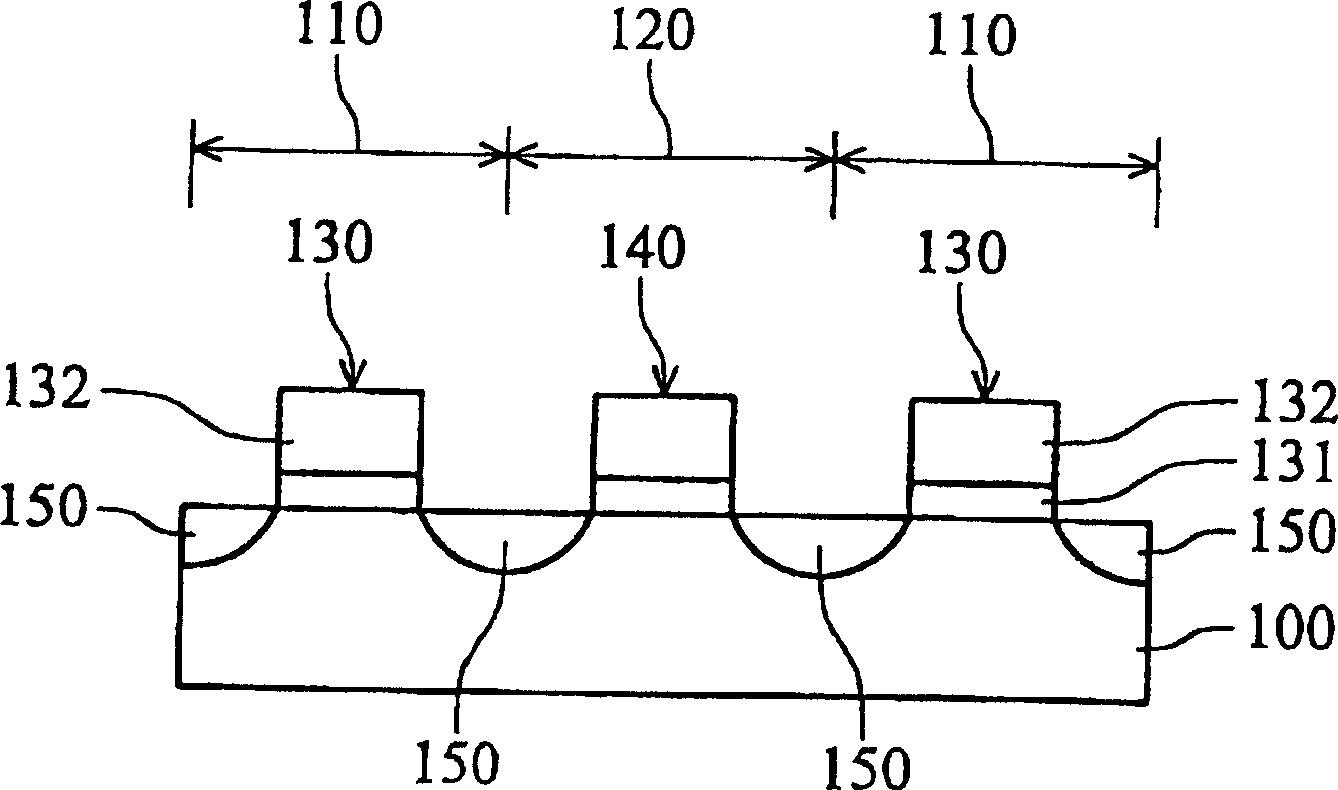

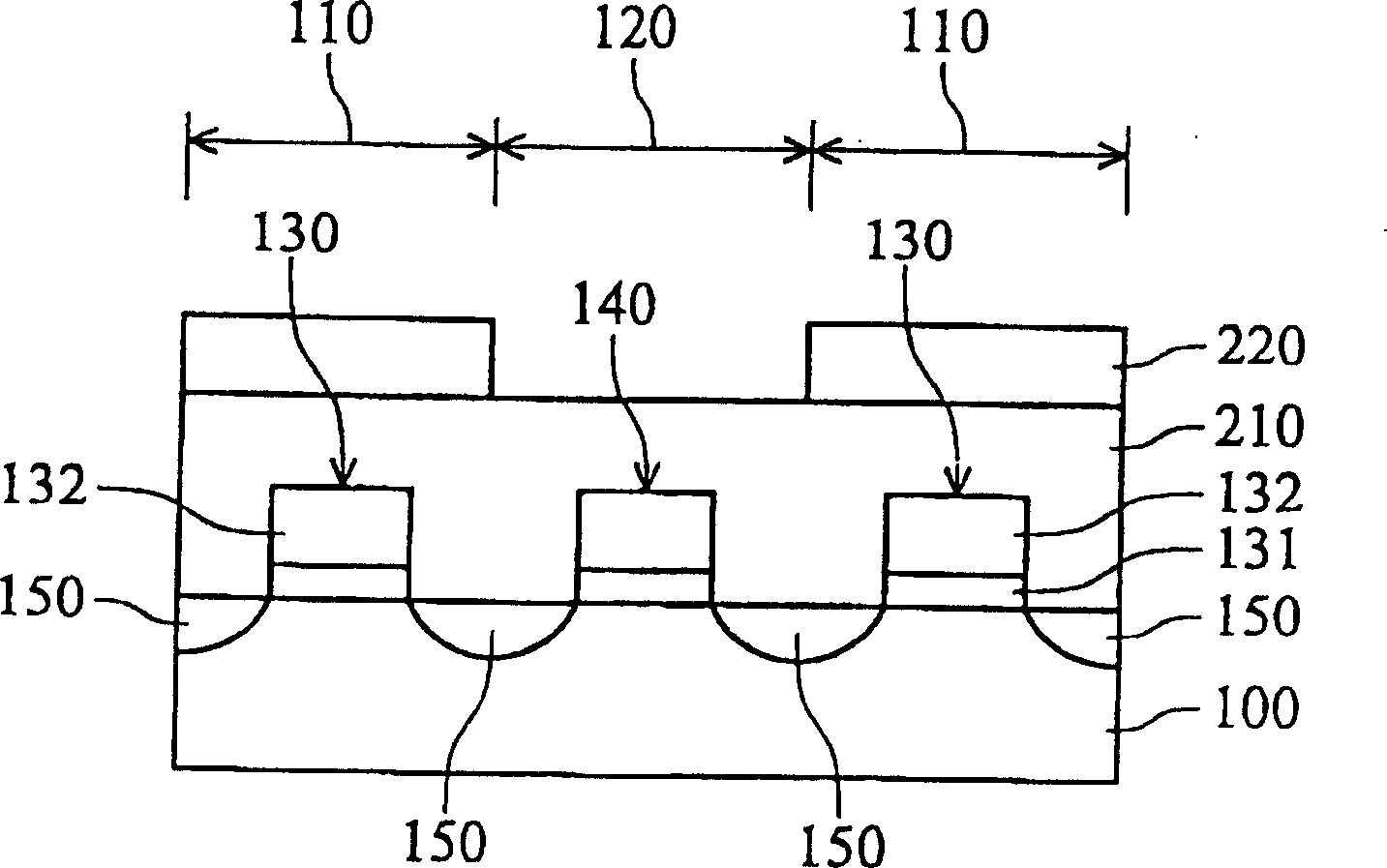

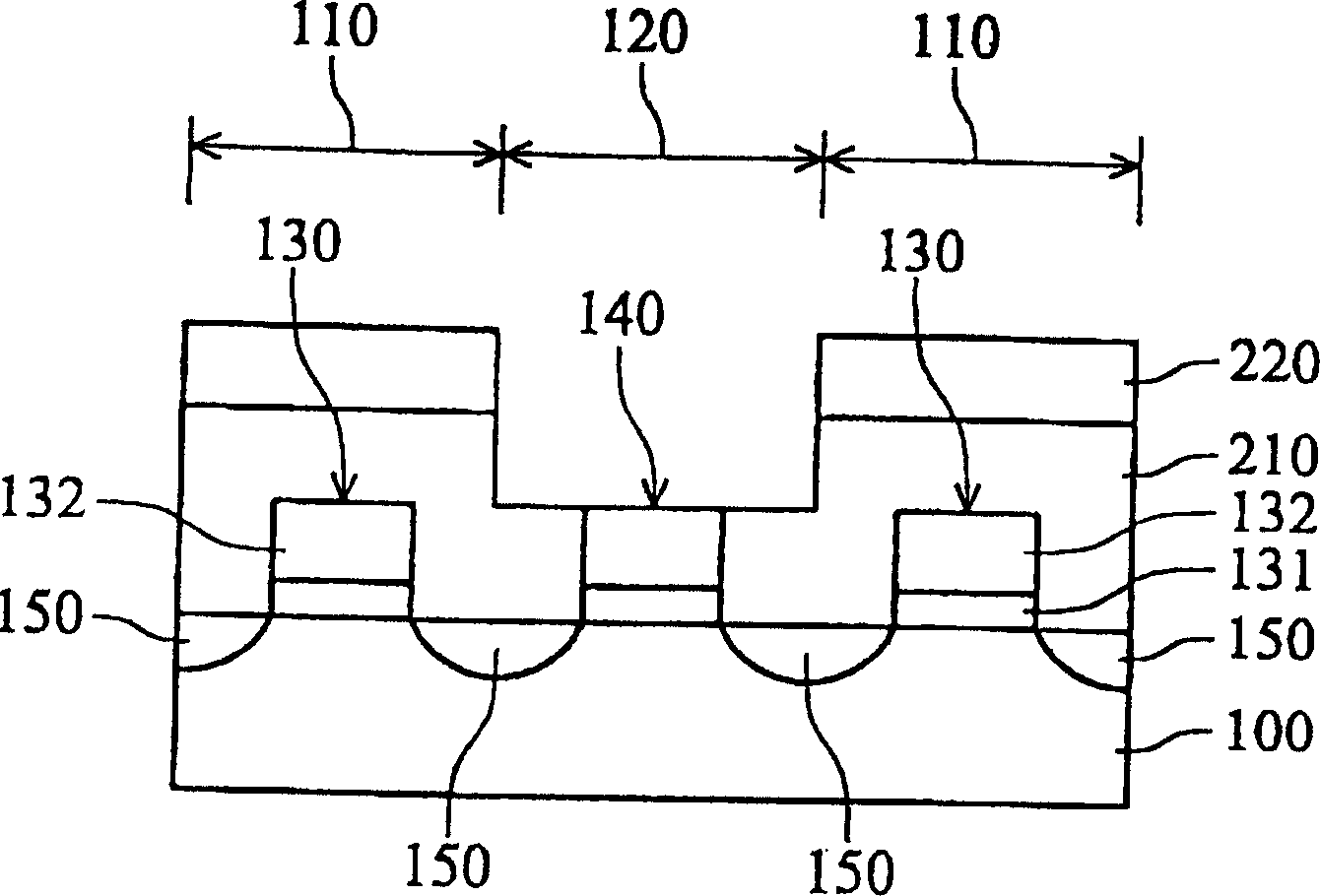

[0010] Use the following Figure 1~6 The process cross-sectional view is shown to illustrate an embodiment of the present invention.

[0011] First, if figure 1 As shown, it provides a semiconductor substrate 100, such as silicon, with a plurality of predetermined active regions (active areas) 110 on the substrate 100, and at least one predetermined isolation region (an isolation area) 120.

[0012] exist figure 1 In this method, a first gate structure 130 is formed on a part of the substrate 100 in the active region 110 , and a second gate structure 140 is formed on the substrate 100 in the isolation region 120 . An example is given here to illustrate the process of forming the first and second gate structures 130, 140. First, thermal oxidation or deposition is used to form, for example, SiO 2 An insulating layer (not shown) is on the substrate 100, and then a conductive layer (not shown) such as a polysilicon layer is formed on the insulating layer by deposition. Then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com