Power lumbar mechanism

A driving mechanism, waist technology, applied in vehicle parts, movable seats, transportation and packaging, etc., can solve problems such as linear offset that cannot meet the screw thread size and time, and difficulty in providing power from a central vortex tube.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

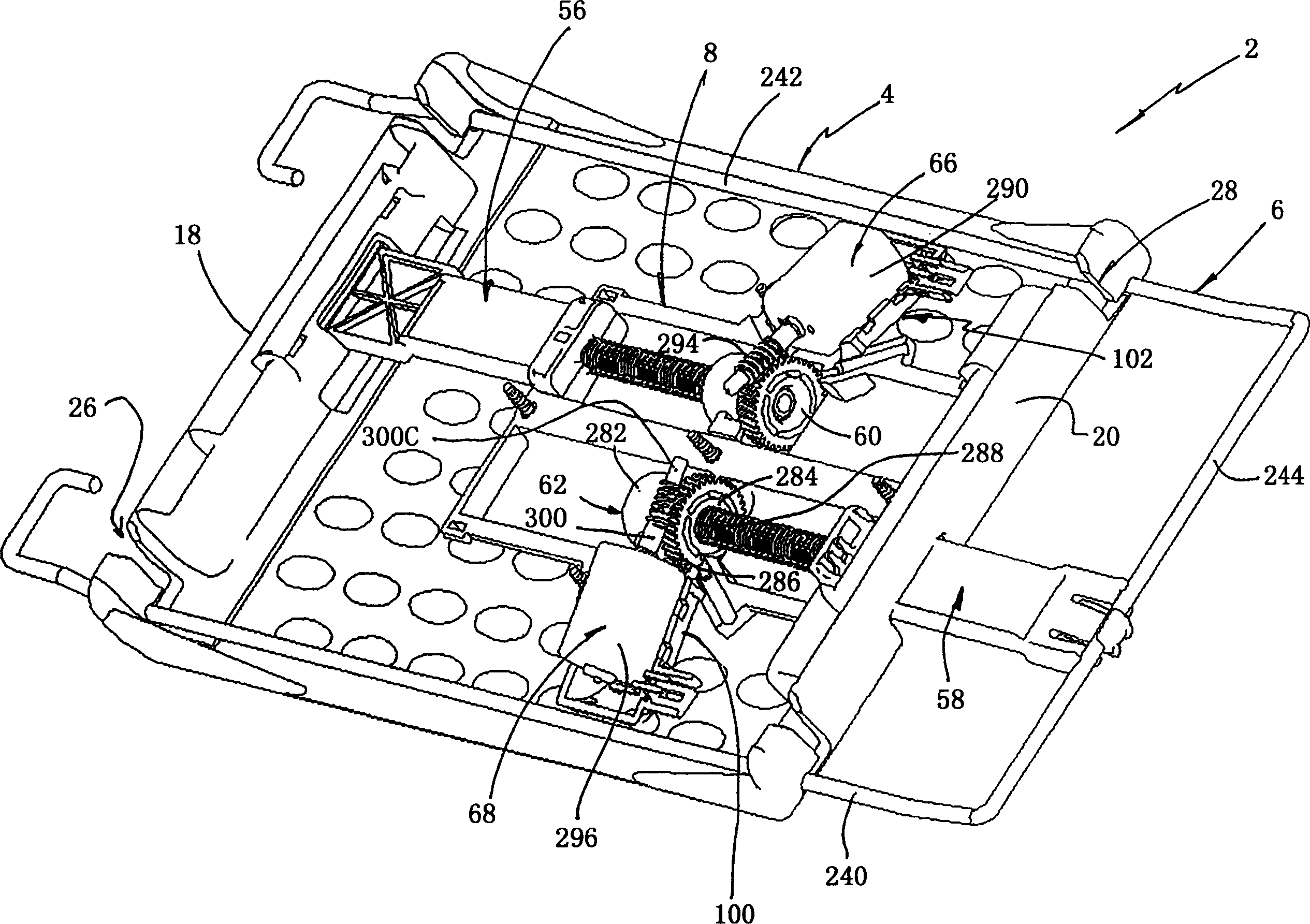

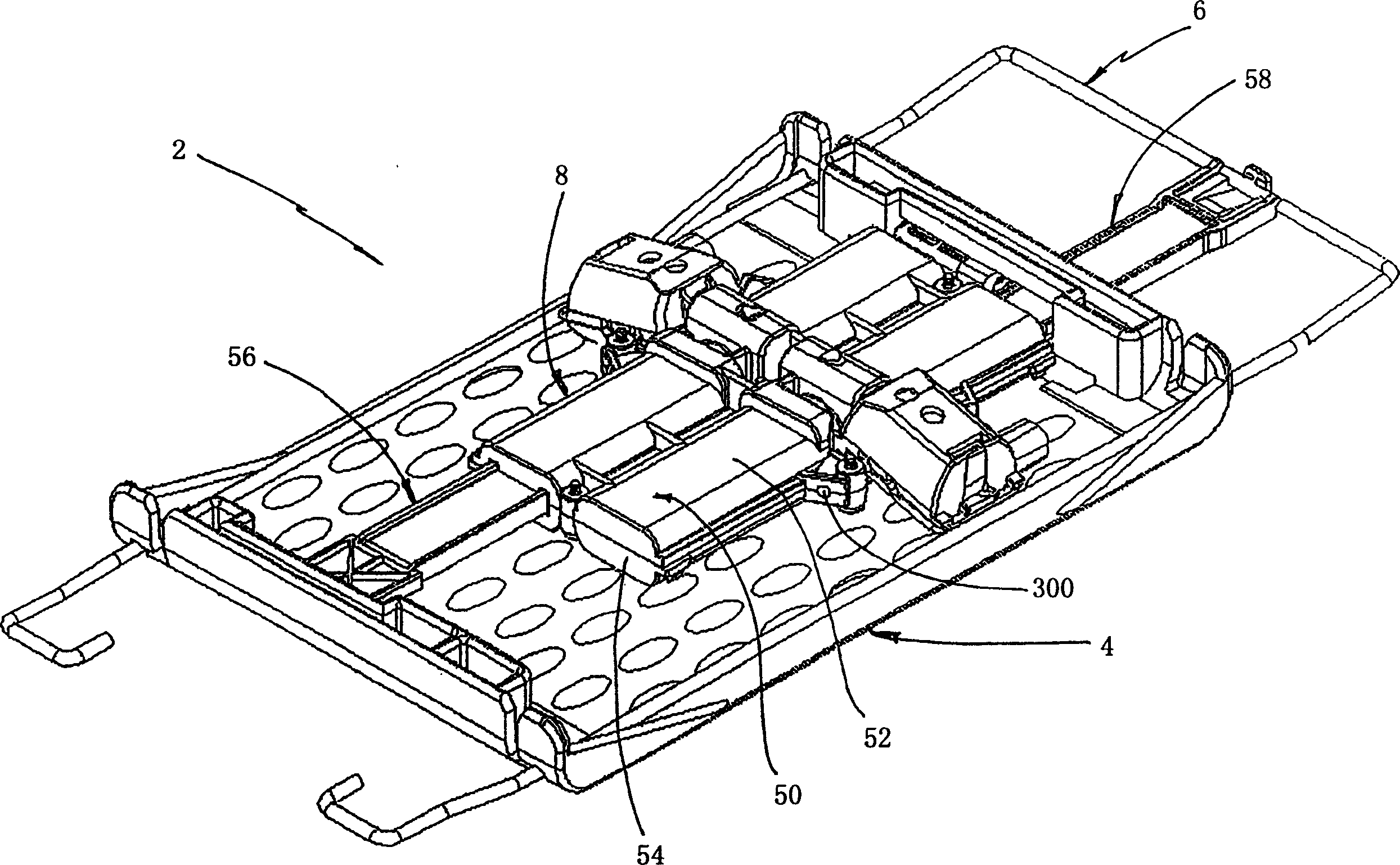

[0034] First refer to figure 1 and 2, the power lumbar mechanism is generally indicated by reference numeral 2, which includes a curved plate 4, which is slidably connected with the support structure 6 in the backrest of the seat, and the driving mechanism 8 attached to the lumbar mechanism is used to change the curved plate 4 The curvature and the position of the plate 4 relative to the support structure 6.

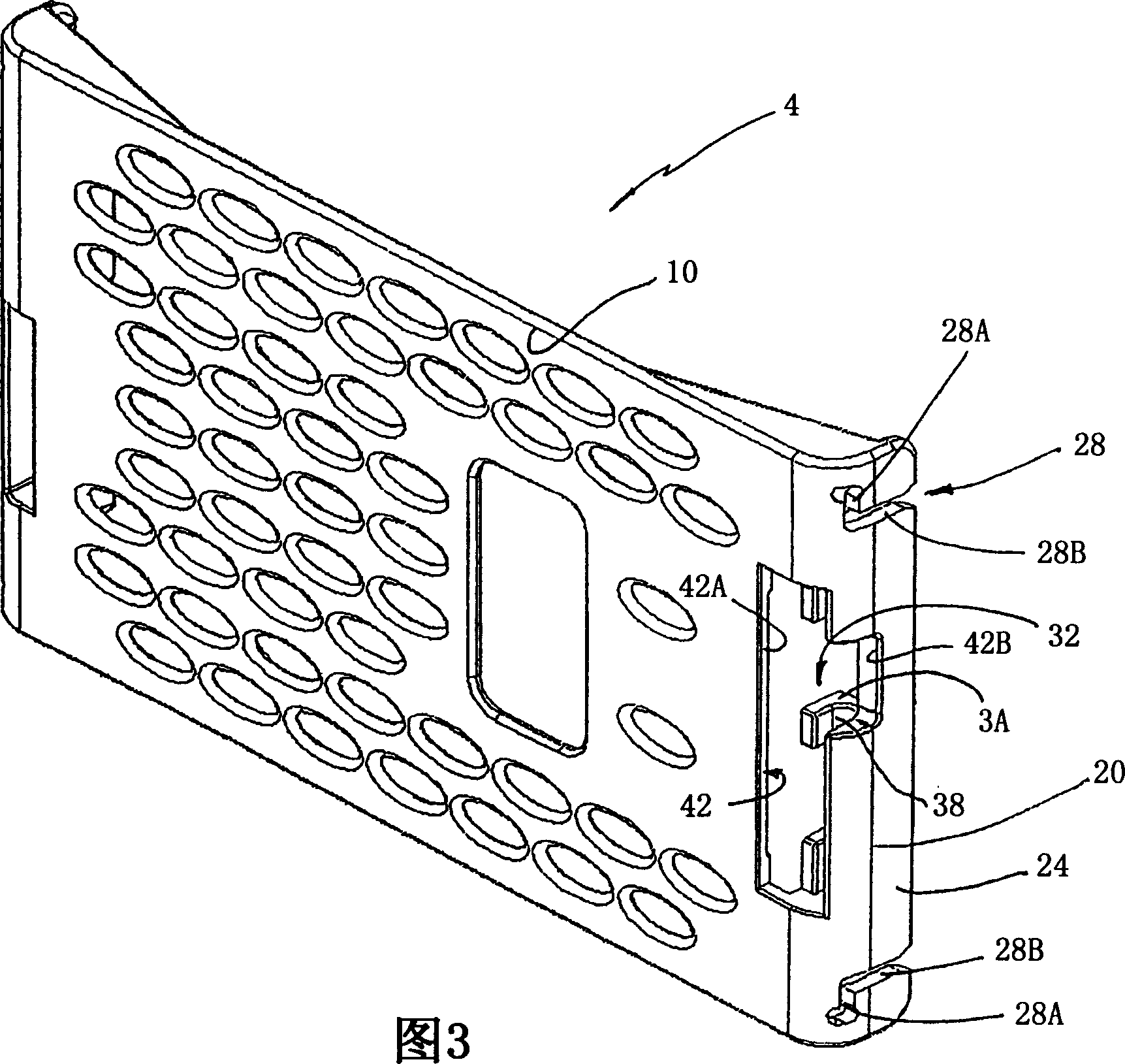

[0035] The curved plate, which includes an outer contact surface 10, an inner surface 12, sides 14, 16, and end edges 18, 20, will now be described in further detail with reference to FIGS. End edges 18 , 20 include straight sides 22 , 24 each of which includes an L-shaped groove 26 , 28 . These L-shaped slots include horizontal slot sections 26A, 28A and vertically extending slot sections 26B, 28B. Each end 18, 20 further includes a trunnion portion 30, 32, wherein each trunnion includes a slotted portion 34, 36 and a channel portion 38, 40, which will be further des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com