Large-scale three dimensional shape and appearance measuring and splicing method without being based on adhesive mark

A shape measurement and marking technology, which is applied in the field of precision measurement, can solve the problems of destroying the characteristics of the measured shape itself, increasing the error of automatic recognition, and affecting the authenticity of the measurement, so as to achieve true and reliable measurement data, deceleration errors, and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

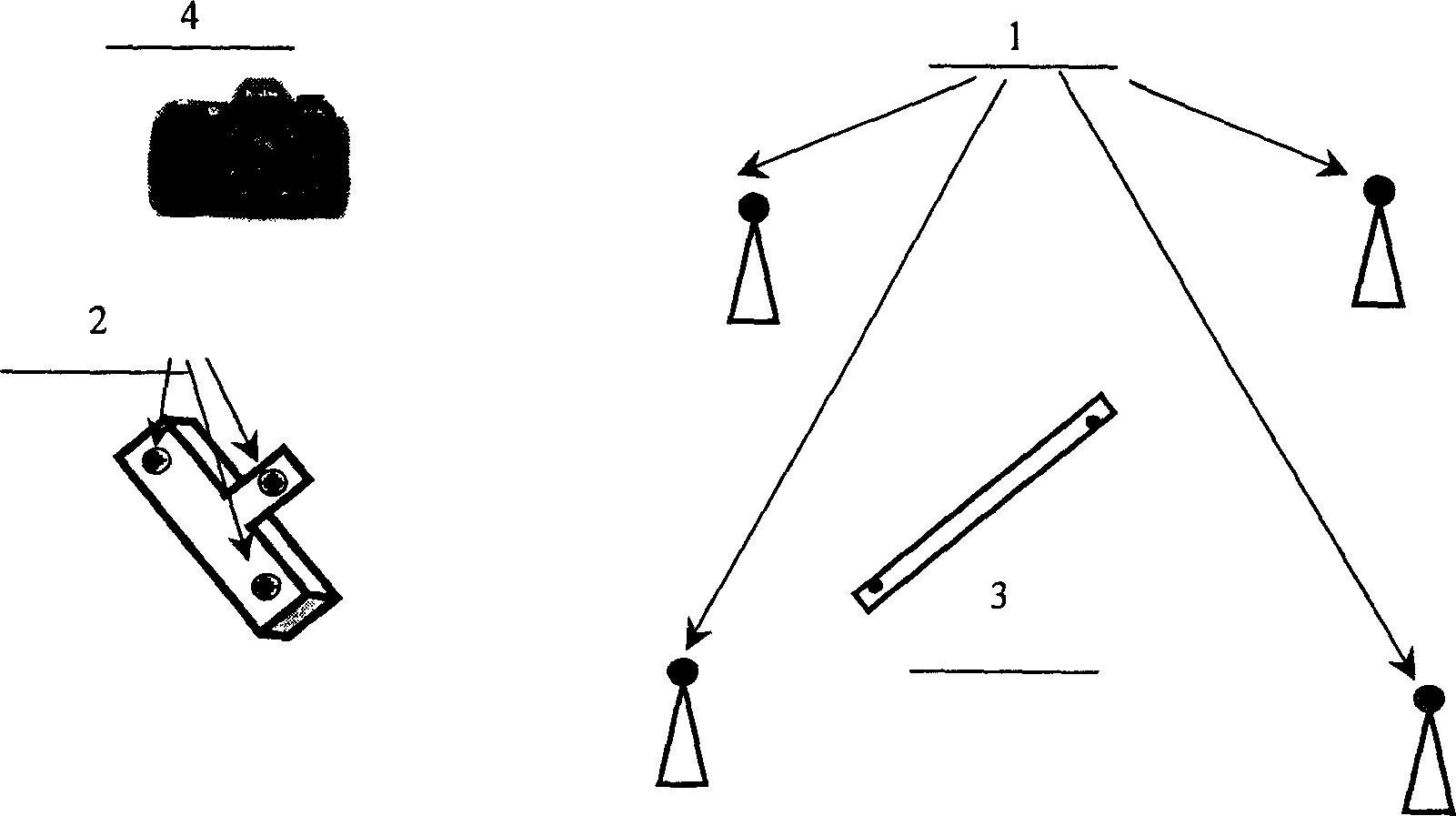

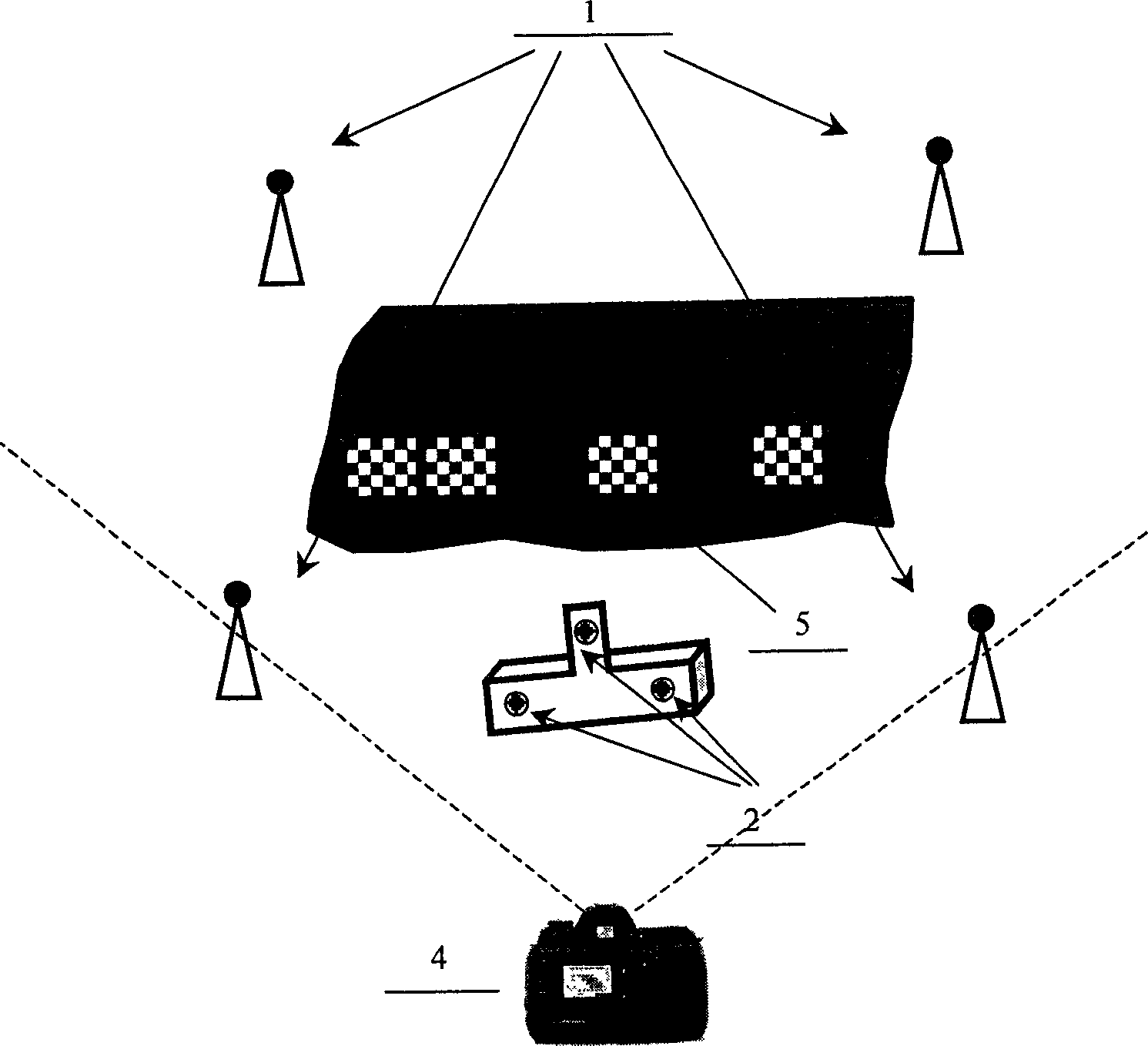

[0022] Such as figure 2 As shown, more than 4 global control points are placed in the measured space. The number of global points can be determined according to the actual requirements (the size of the measured object). The global control points are positioned at the center of the precision sphere. Three (or more) probe control points are fixed on the optical probe, and the probe control points are positioned by the center of a precision sphere or the center of a plane circle. The coordinates of the control points on the probe in the probe measurement coordinate system are pre-calibrated.

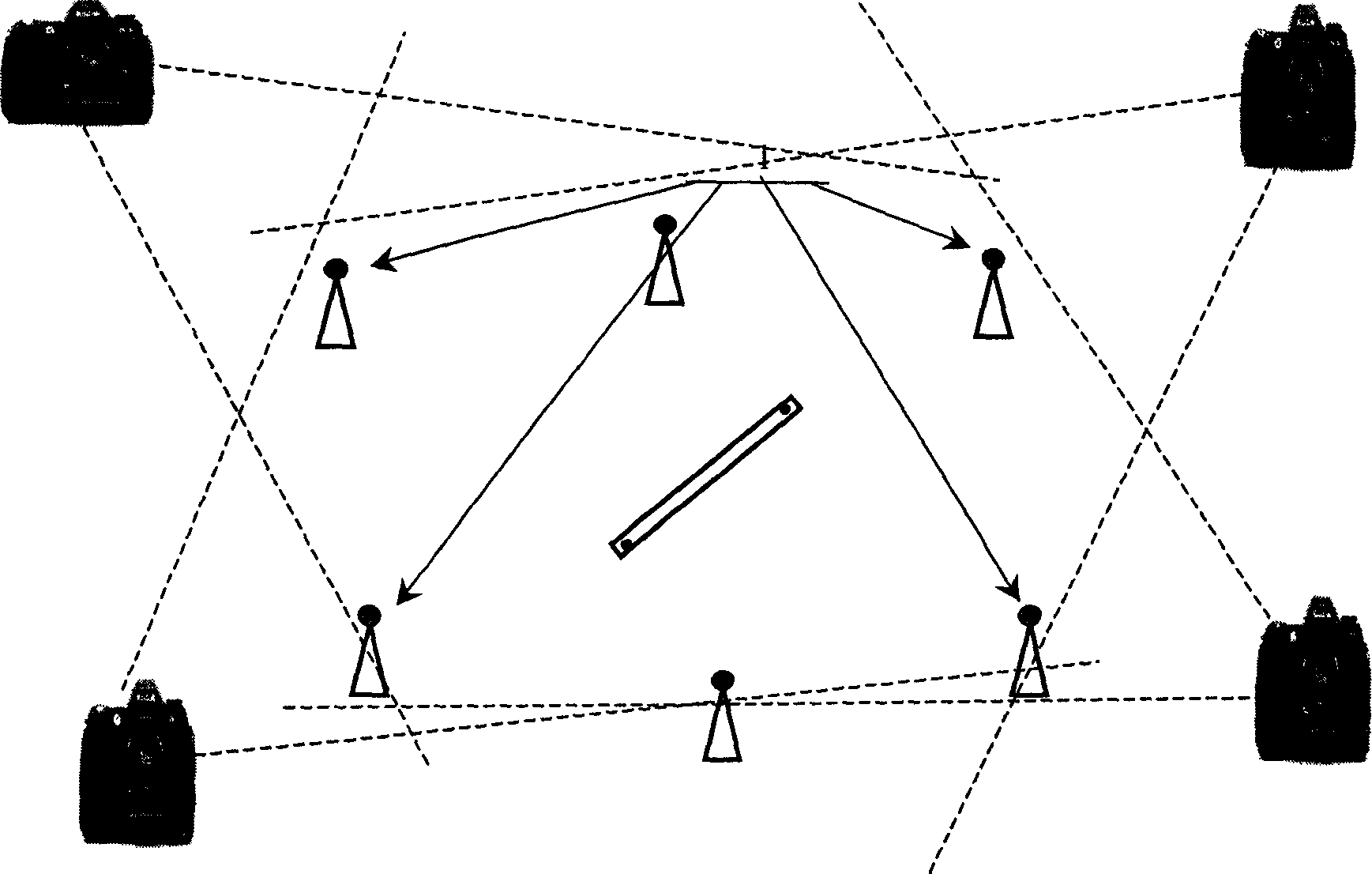

[0023] When measuring, first, use a digital camera to take images containing all global control points from multiple angles, and obtain the global control points in the global coordinate system O g x g Y g Z g The spatial coordinate value in ; secondly, the optical probe measures each area of the measured object one by one, and when measuring each area S i when, such as image 3, u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com