Automatic gear shifting mechanism for vehicle

An automatic transmission and operating device technology, applied in the direction of transmission control, control devices, vehicle components, etc., can solve the problems of wire rack installation position restrictions, loud operation sound, and durability deterioration, so as to avoid durability deterioration and reduce Small operation sound, effect of reducing width size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, embodiments of the present invention will be specifically described with reference to the drawings.

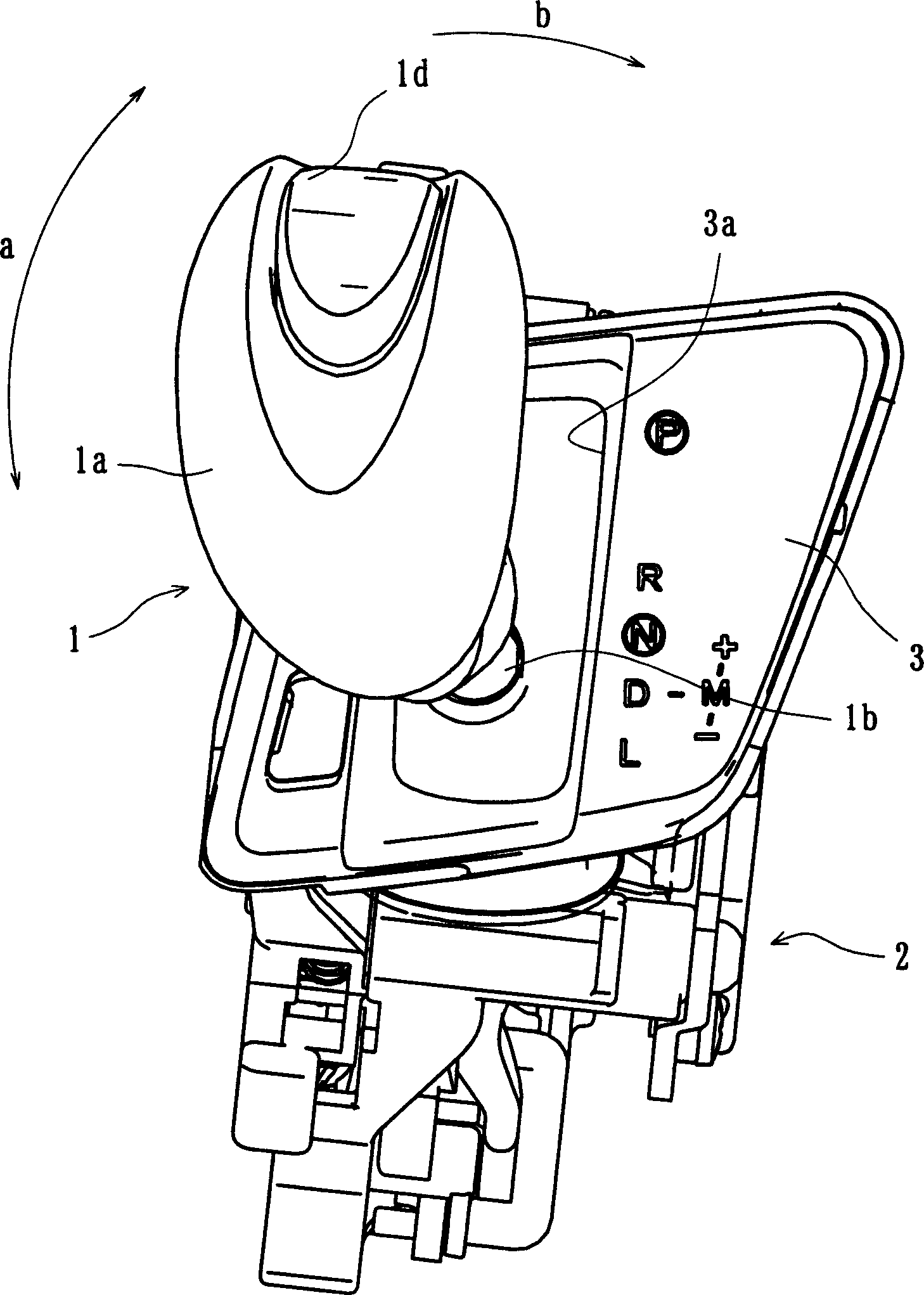

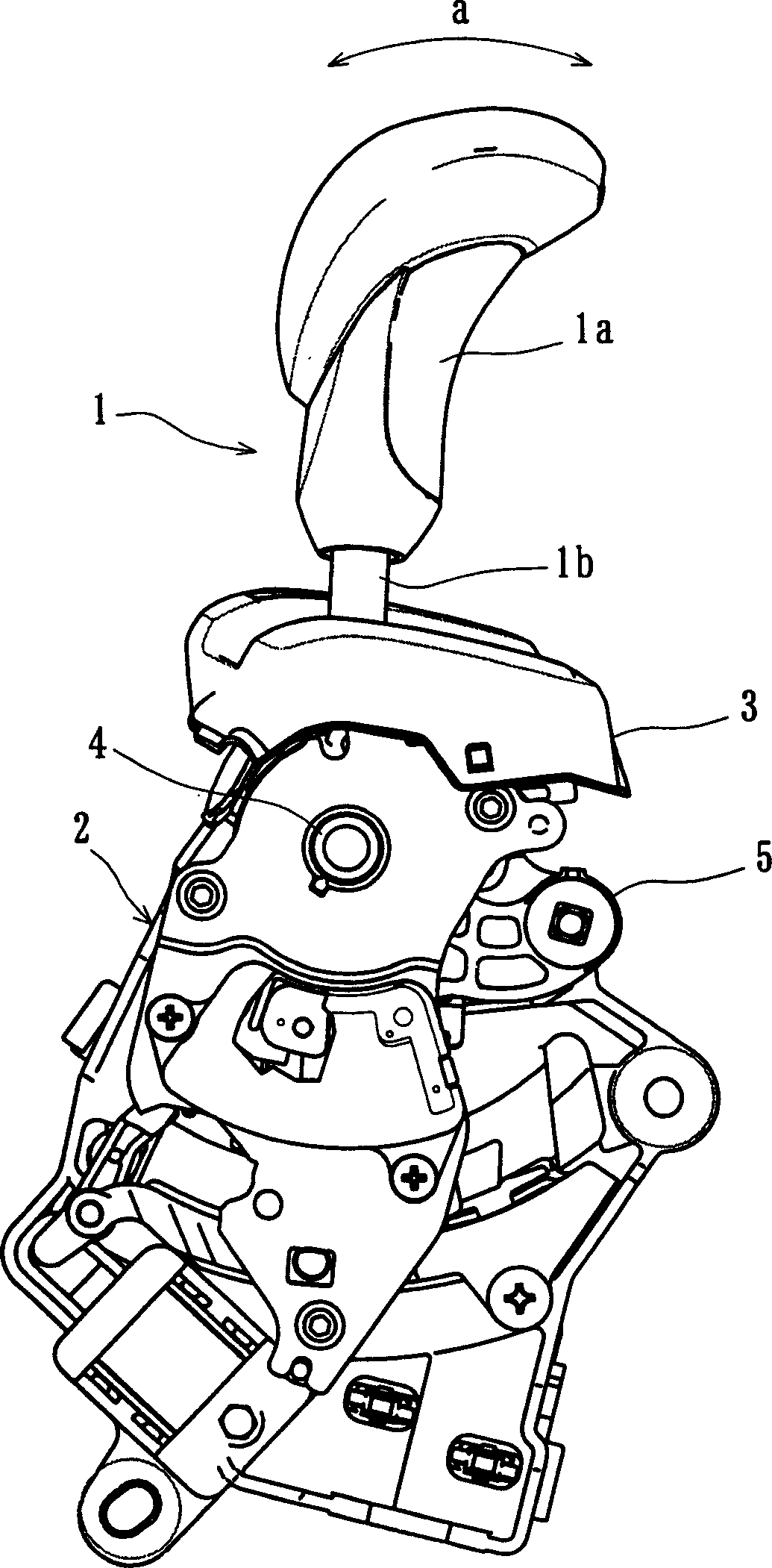

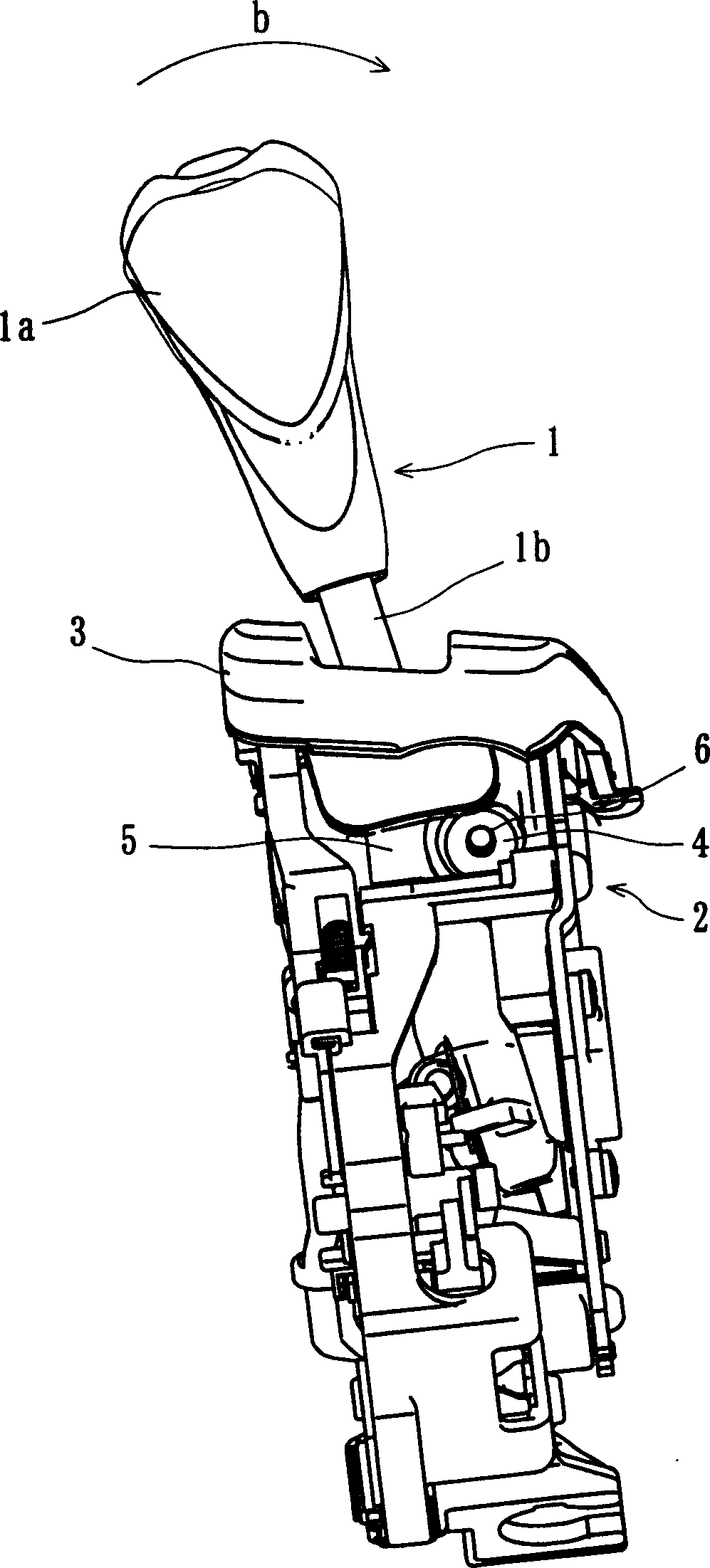

[0034] The automatic transmission operating device for vehicles involved in this embodiment can arbitrarily set the automatic mode and the manual mode, such as Figure 1 ~ Figure 3 As shown, in appearance, it is mainly composed of a shift lever 1, a bracket 2 fixed on the vehicle body, and a cover plate 3 covering the surface of the bracket 2, wherein the shift lever 1 is mainly composed of a handle part 1a and a rod part 1b .

[0035]The shift lever 1 is supported so that components such as the bracket 2 and the cover plate 3 fixed on the vehicle body relative to the cover plate can swing to the front and rear direction (a direction in the figure) of the vehicle body, and can swing to the left and right direction (b direction in the figure). direction) to pour, so in the normal state, the automatic mode is formed by shaking in the forward and backward dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com