Method and equipment for producing ornaments parts

A technology for manufacturing equipment and manufacturing methods, applied in clothing, applications, jewelry, etc., can solve problems such as reduced production efficiency, poor pattern fineness, and insufficient refinement, and achieve the effects of reducing production costs, improving tightness, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

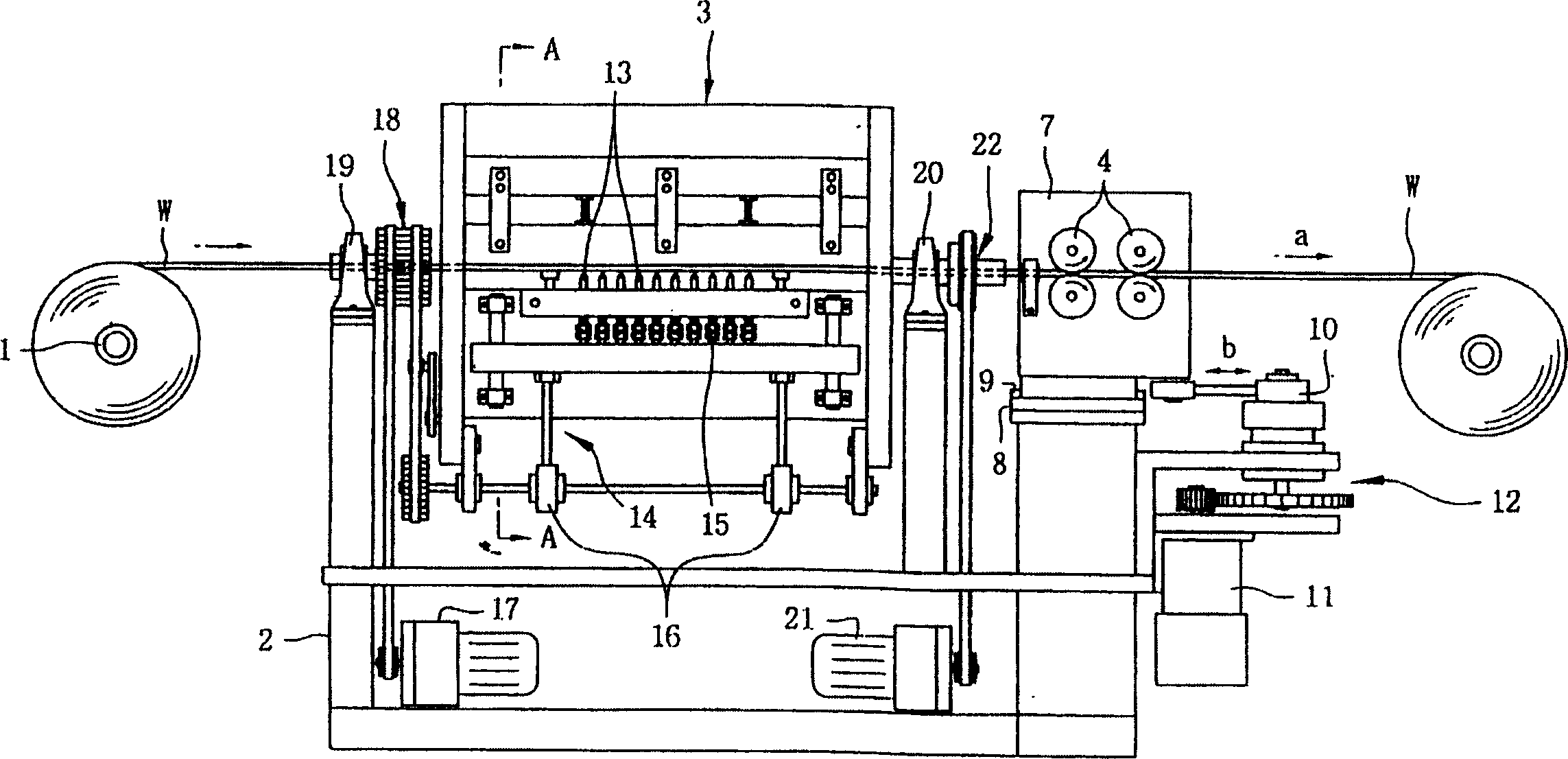

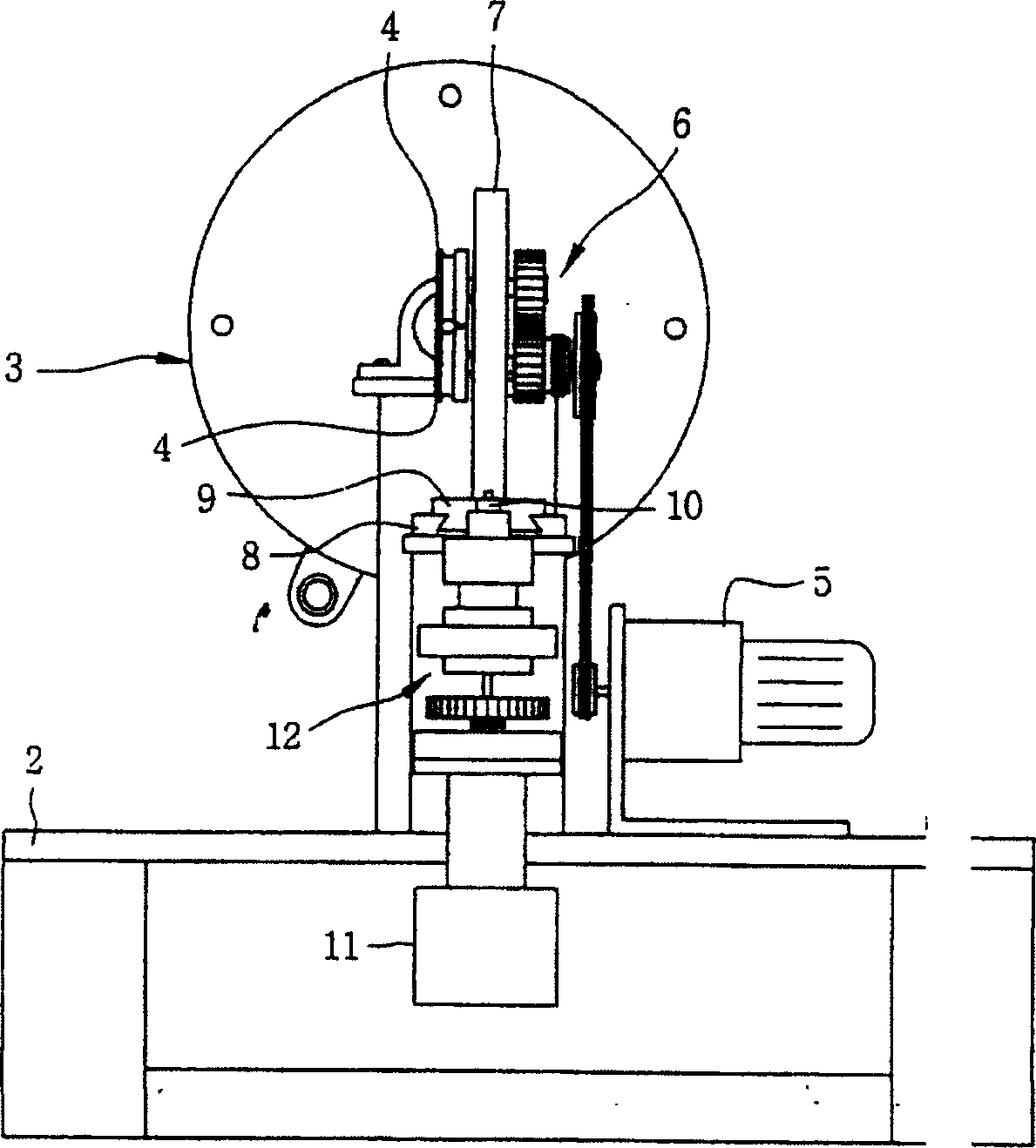

[0026] The overall structure of jewelry manufacturing equipment of the present invention is as figure 2 As shown, it comprises a frame 2, and at least one through hole is respectively arranged on the left and right ends of the top of the frame 2, and the diameter of the through hole is slightly larger than the metal wire W to be processed; all through holes are coaxial, forming a A channel for the smooth feeding of the wire W.

[0027] The left reel 1 is set on the left side of the frame 2, which is used to wind the part of the metal wire W that has not been subjected to surface pattern processing; the right reel 1' is set on the right side of the frame 2, and is used to wind the surface pattern on the wire W. processed part.

[0028] The pattern processing of the metal wire W is completed by the stamping device 15, which is arranged in the middle of the upper part of the frame 2; when the metal wire W passes through its channel, patterns are stamped on the surface of the me...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap