Efficient fluidized catalytic converting steam stripping device

A technology of fluidized catalysis and stripper, applied in chemical instruments and methods, chemical/physical processes, distillation and separation, etc., can solve the problems of reducing oil and gas concentration difference, affecting stripping effect, and difficult to improve stripping effect, etc., to achieve Improvement of yield and reduction of regeneration load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

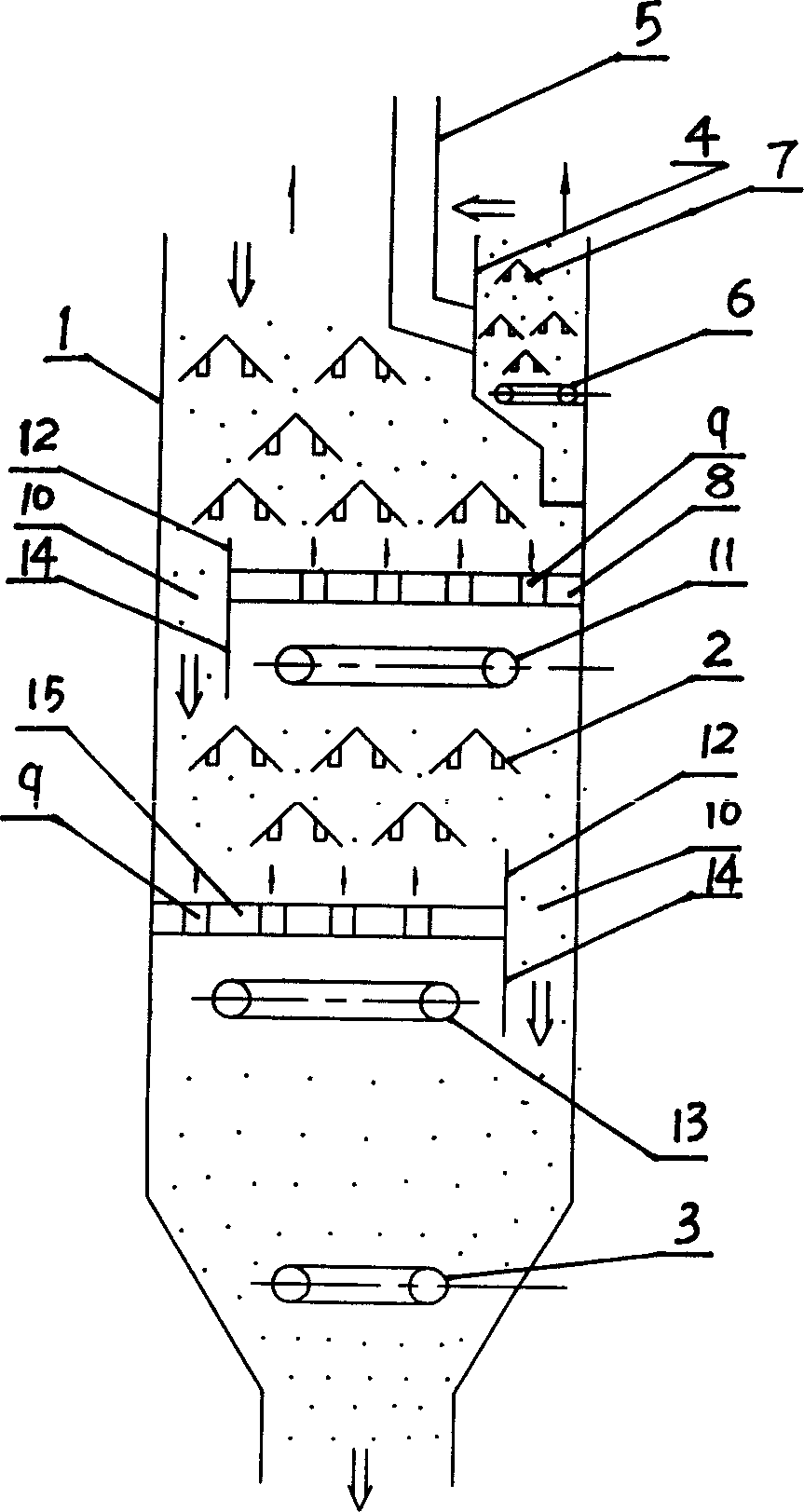

Embodiment 1

[0021] Embodiment 1. A high-efficiency fluidized catalytic conversion stripper, comprising a cylinder body 1 with multi-layer baffles 2 inside, a steam inlet 3 on the lower part of the cylinder body 1, and a waste gas outlet on the upper part. The inner side of the upper part of cylinder body 1 is provided with an initial stripper in parallel, the side of the cylinder body 4 of the initial stripper is provided with an oil catalyst inlet pipe 5, the lower part is provided with a steam inlet 6, and the upper part is provided with a waste gas outlet, the initial stripper cylinder body 4 The upper end of the inner side is not higher than the upper end of the cylinder 1, and the cylinder 4 of the initial stripper is provided with a multi-layer baffle 7. A partition 8 is arranged between two adjacent baffles 7 in the middle of the cylinder 1, and a vent hole 9, a weir 12, and an agent-reducing pipe 10 are arranged on the partition 8, and the agent-reducing pipe 10 extends out of the ...

Embodiment 2

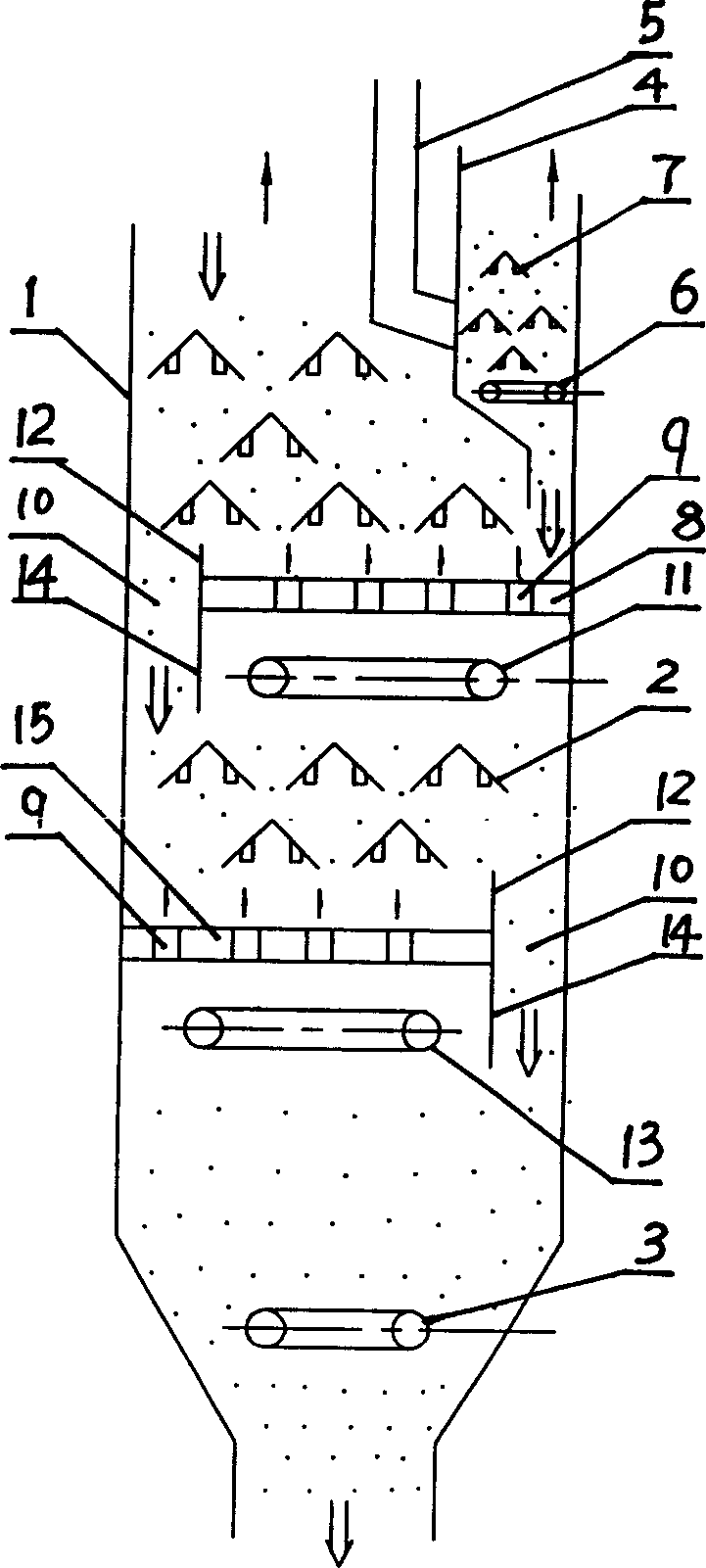

[0022] Embodiment 2. In this embodiment, the upper end of the cylinder body 4 of the initial stripper is higher than the upper end of the cylinder body 1, and the lower end of the initial stripper is connected with the cylinder body 1, and the catalyst after the initial stripping directly enters the cylinder body 1 for subsequent stage steaming. carry. Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com