Refrigerant distributor for heat exchanger and its assembling method

A refrigerant distribution and heat exchanger technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., to achieve the effects of reducing eddy currents, reducing overall noise, and simplifying the assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

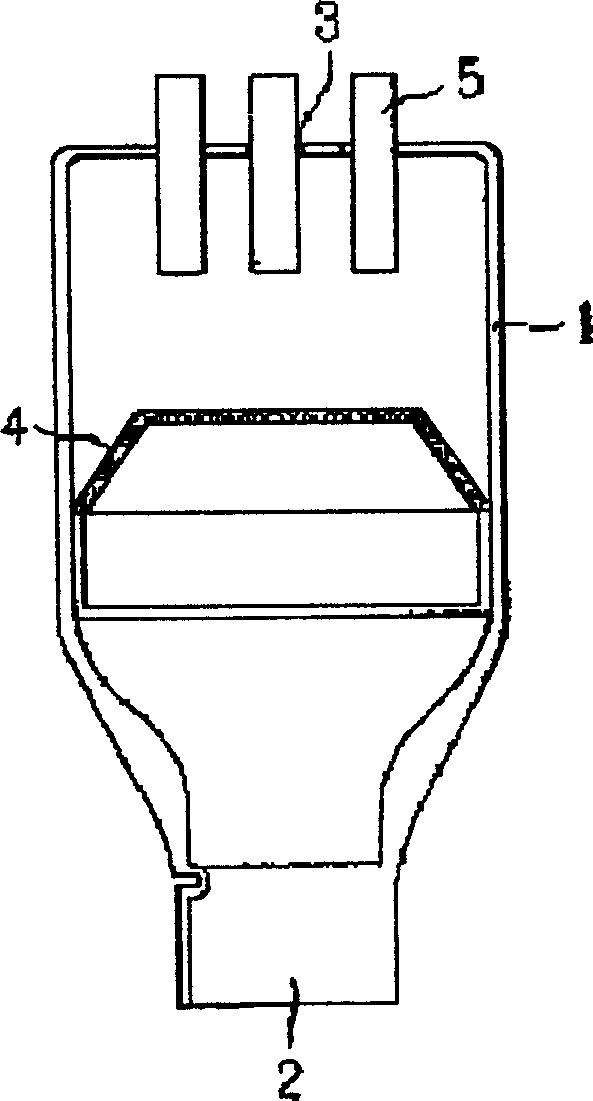

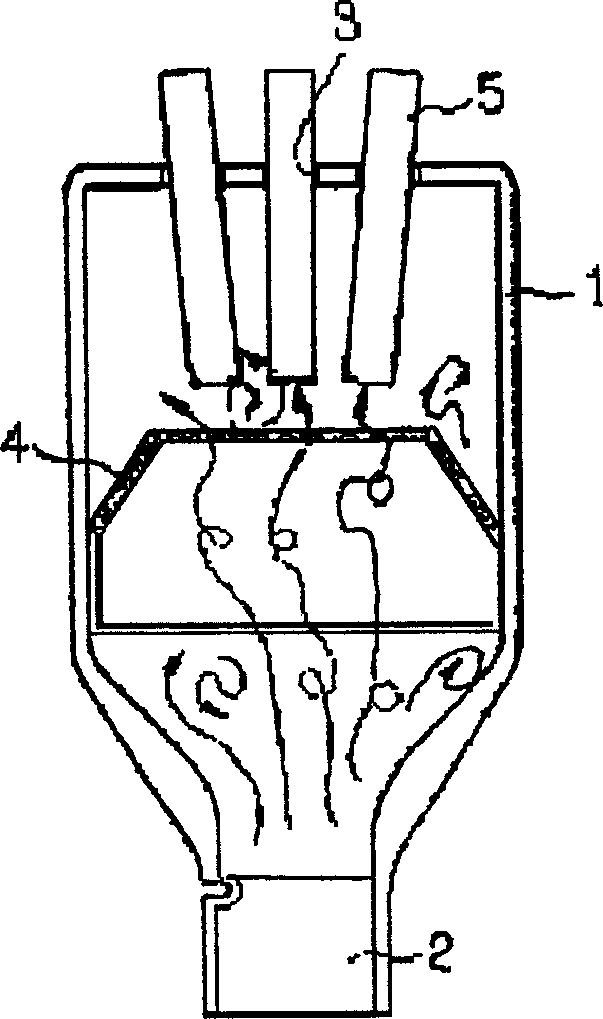

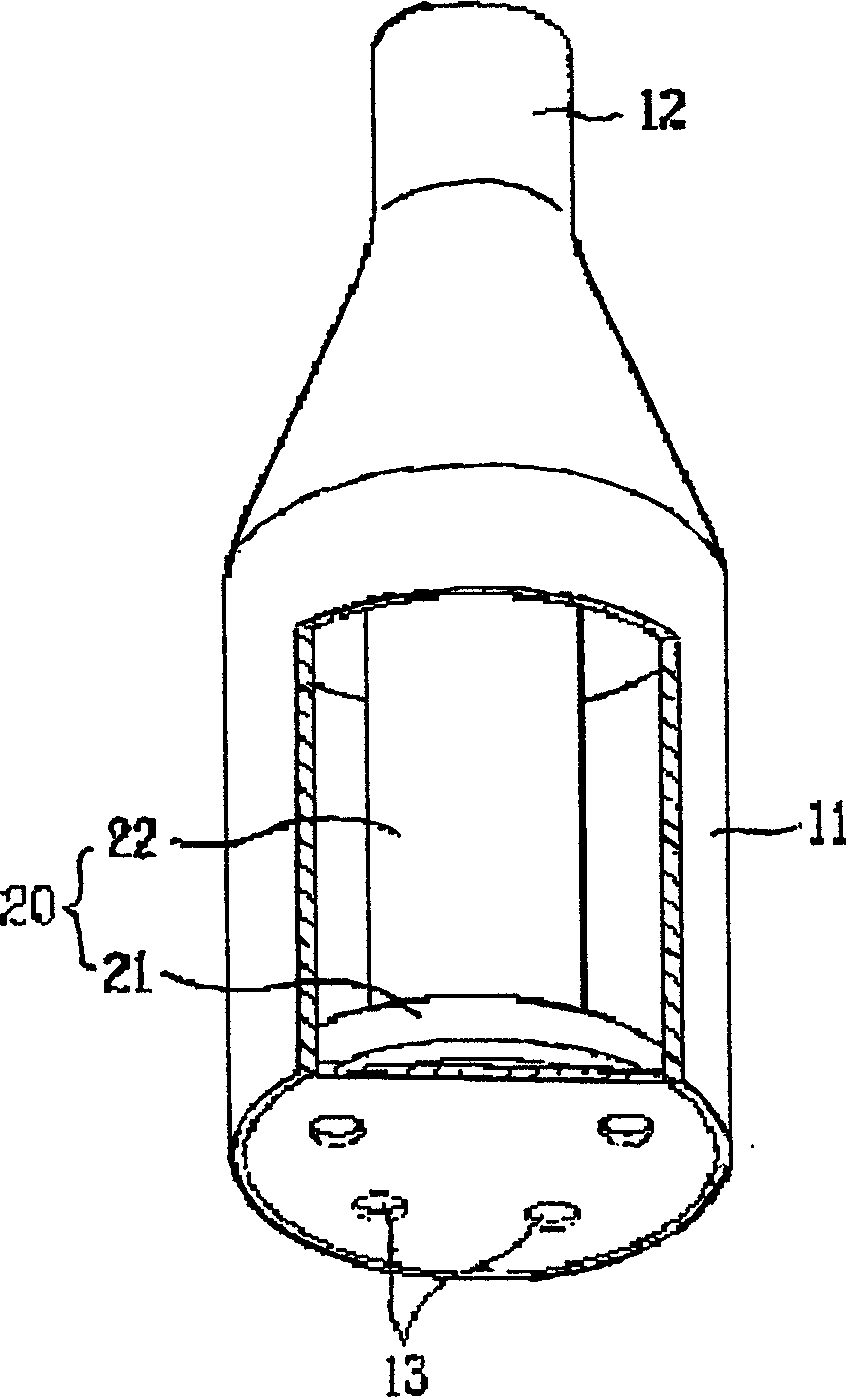

[0032] Such as image 3 , Figure 4 and Figure 5 As shown, the refrigerant distributor for heat exchangers of the present invention includes: a distributor body 11, a refrigerant pipe 15, and a homogenizing component 20; the distributor body 11 is in the shape of a hollow cylinder, with a refrigerant inlet 12 formed at one end, and One end is closed to form a bottom surface with several through holes 13; the refrigerant pipes are respectively inserted into the interior of the distributor body through the through holes; the homogenization component 20 is arranged on the distributor body 11 along the length direction of the distributor body 11 internal central location.

[0033] The homogenizing component 20 includes: a disc-shaped fixed plate 21 and a guide post 22; the disc-shaped fixed plate 21 is fixed on the inner wall of the bottom surface of the body 11 formed with the through hole 13, and the fixed plate 21 An annular through-groove 21 a that can be inserted into the...

Embodiment 2

[0036] Such as Figure 6 As shown, the guide column 122 is in the shape of a cylinder, and several refrigerant pipe guide grooves 123 are formed on its outer peripheral surface along the length direction.

Embodiment 3

[0038] Such as Figure 7 As shown, the guide post 222 is in the shape of a truncated cone, and its diameter gradually increases along the direction from the inlet 12 to the through hole 13 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com